Aliphatic water reducer residual polymer treatment method

An aliphatic water-reducing agent and processing method technology, applied in the chemical field of building materials, can solve problems such as long-term stacking, and achieve the effects of improving concrete plasticity, solving segregation, and ensuring setting time and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The residual polymer of the aliphatic water reducer is dried in natural air.

[0053] Jaw crush and ball mill the dried residual polymer of aliphatic water reducer to obtain granular residual polymer of aliphatic water reducer. Add 30% fly ash;

[0054] Sieve the residual polymer of the aliphatic water reducer after grinding, and select the residual polymer of the aliphatic water reducer in a granular form <45 μm as the residual aliphatic water reducer polymer powder;

[0055]According to mass percentage, mechanically mix 75% residual aliphatic water reducer polymer powder, 19% sodium silicate, 5% sodium sulfate, 0.5% methylcellulose and 0.5% sodium lauryl sulfate until uniform, An anti-segregation agent is prepared.

Embodiment 2

[0057] The residual polymer of the aliphatic water reducer is dried in natural air.

[0058] Jaw crush and ball mill the dried residual polymer of aliphatic water reducer to obtain granular residual polymer of aliphatic water reducer. Add 20% mineral powder;

[0059] Sieve the residual polymer of the aliphatic water reducer after grinding, and select the residual polymer of the aliphatic water reducer in a granular form <45 μm as the residual aliphatic water reducer polymer powder;

[0060] Mechanically mix 75% residual aliphatic water reducer polymer powder, 19% sodium silicate, 5% sodium carbonate, 0.5% hydroxypropyl methylcellulose and 0.5% sodium lauryl sulfate by mass percentage Until it is uniform, the anti-segregation agent is prepared.

Embodiment 3

[0062] The residual polymer of the aliphatic water reducer is dried at a low temperature.

[0063] Jaw crush and ball mill the dried residual polymer of aliphatic water reducer to obtain granular residual polymer of aliphatic water reducer. Add 30% limestone powder;

[0064] Sieve the residual polymer of the aliphatic water reducer after grinding, and select the residual polymer of the aliphatic water reducer in a granular form <45 μm as the residual aliphatic water reducer polymer powder;

[0065] According to mass percentage, 70% of residual aliphatic water reducer polymer powder, 28% sodium silicate, 1.0% hydroxymethyl cellulose and 1.0% sodium dodecylbenzenesulfonate were mechanically mixed until uniform, and prepared Anti-segregation agent.

[0066] Application of anti-segregation agent

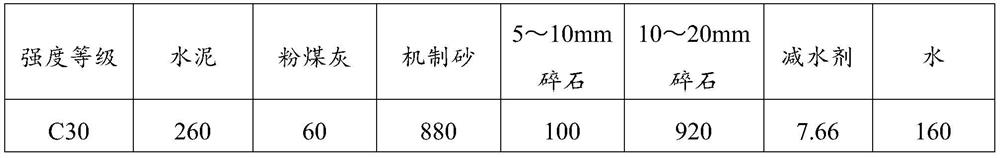

[0067] The anti-segregation agent prepared in Examples 1-3 and the blank sample without anti-segregation agent were compared to test the effect. According to GB8076-2008 "Concrete Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com