Double-color rubber mat at front end of automobile auxiliary instrument board and preparation method thereof

A sub-instrument panel and front-end technology, which is applied to the front-end two-color rubber pad of automobile sub-instrument panel and its preparation field, can solve the problems of affecting product quality, marginal entry of dust, poor flame retardancy, etc., so as to avoid the deterioration of material properties and processing difficulties. , Improve the effect of high temperature resistance, the effect of high decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

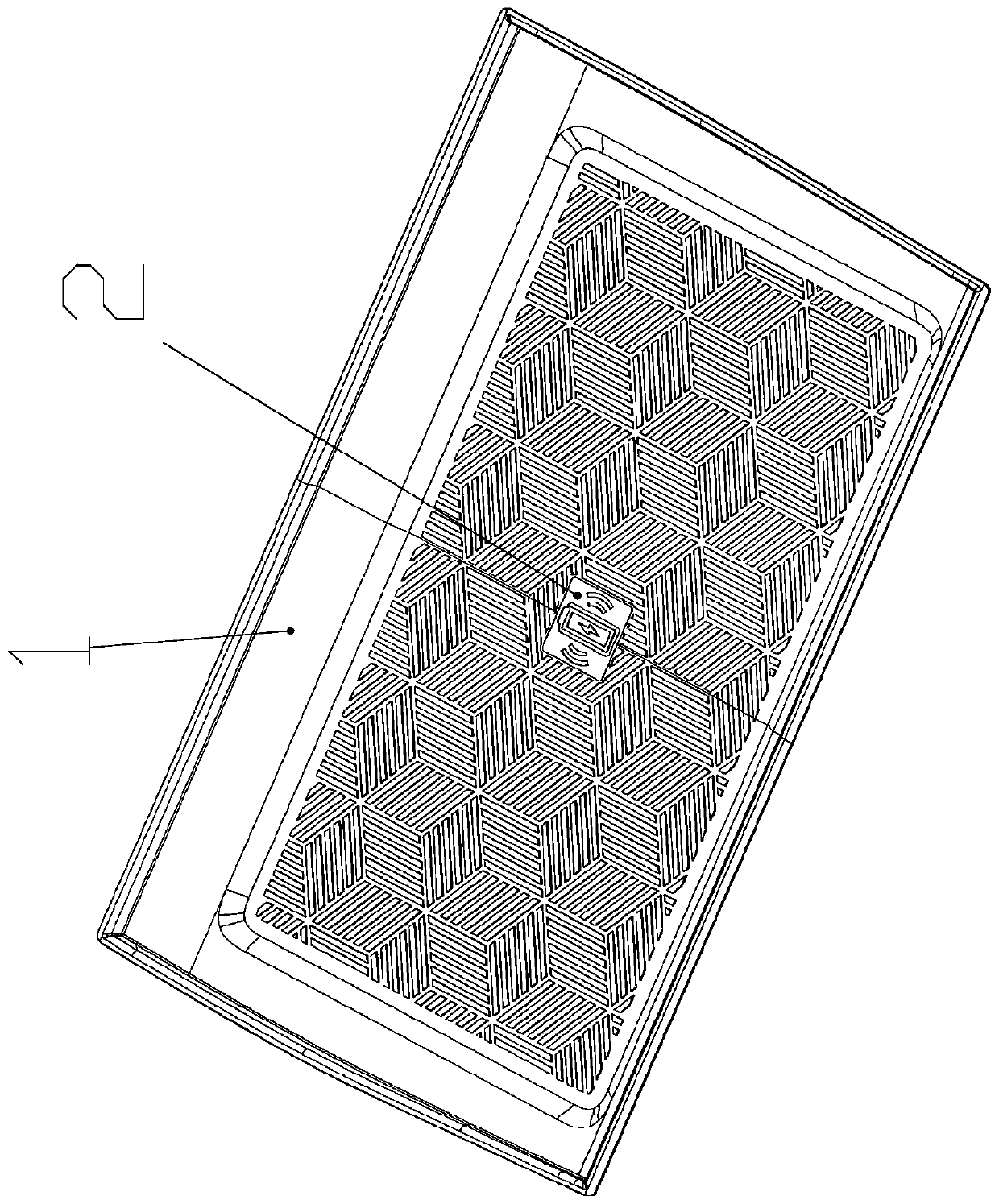

[0025] Such as figure 1 As shown, the two-color rubber pad at the front end of an automobile sub-dashboard provided by this embodiment includes a black rubber layer 11 with a square structure and a red rubber layer 22 located at the center of the black rubber layer 11. The black rubber layer 11 and the red rubber layer The rubber layer 22 is formed by integral injection molding. The black rubber layer 11 includes raw materials according to the following proportions: 40-50 parts of TPS thermoplastic elastomer, 10-15 parts of PP, 5-8 parts of paraffin-based filler oil, 5-12 parts of diatomite, 3-5 parts of impact modifier, 5-10 parts of binder, 12-15 parts of phosphorus / nitrogen / silicon ternary composite flame retardant, 1-8 parts of flame retardant synergist and melanin, the red rubber layer 22 includes raw materials according to the following ratios: 20-30 parts of TPS thermoplastic elastomer, 3-8 parts of PP, 1-5 parts of paraffin-based filler oil, and 2 parts of diatomaceous...

Embodiment 2

[0041] This embodiment provides a two-color rubber pad at the front end of an automobile sub-dashboard, comprising a square-shaped black rubber layer 11 and a red rubber layer 22 located at the center of the black rubber layer 11, the black rubber layer 11 and the red rubber layer 22 Formed by integral injection molding, the black rubber layer 11 includes raw materials in the following proportions: 42 parts of TPS thermoplastic elastomer, 13 parts of PP, 6 parts of paraffin-based filler oil, 8 parts of diatomaceous earth, impact resistance 4 parts of modifier, 7 parts of binder, 13 parts of phosphorus / nitrogen / silicon ternary composite flame retardant, 4 parts of flame retardant synergist and melanin, the red rubber layer 22 includes Raw materials: 22 parts of TPS thermoplastic elastomer, 5 parts of PP, 3 parts of paraffin-based filler oil, 3 parts of diatomaceous earth, 2 parts of impact modifier, 3 parts of binder, phosphorus / nitrogen / silicon ternary composite resistance 6 par...

Embodiment 3

[0048] This embodiment provides a two-color rubber pad at the front end of an automobile sub-dashboard, comprising a square-shaped black rubber layer 11 and a red rubber layer 22 located at the center of the black rubber layer 11, the black rubber layer 11 and the red rubber layer 22 Formed by integral injection molding, the black rubber layer 11 includes raw materials in the following proportions: 40 parts of TPS thermoplastic elastomer, 10 parts of PP, 5 parts of paraffin-based filler oil, 5 parts of diatomaceous earth, impact resistance 3 parts of modifier, 5 parts of binder, 12 parts of phosphorus / nitrogen / silicon ternary composite flame retardant, 1 part of flame retardant synergist and melanin, the red rubber layer 22 includes Raw materials: 20 parts of TPS thermoplastic elastomer, 3 parts of PP, 1 part of paraffin-based filler oil, 2 parts of diatomaceous earth, 1 part of impact modifier, 1 part of binder, phosphorus / nitrogen / silicon ternary composite resistance 5 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com