Step-by-step axial extrusion throttling device of elastic double rubber tube

A throttling device, elastic technology, applied in wellbore/well components, sealing/packing, earth-moving drilling, etc., to achieve the effect of easy unsealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

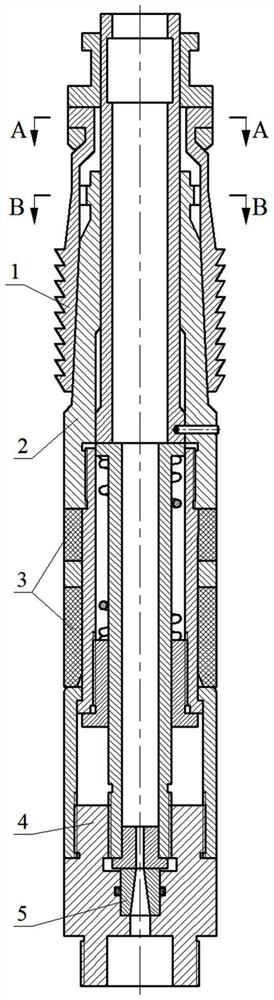

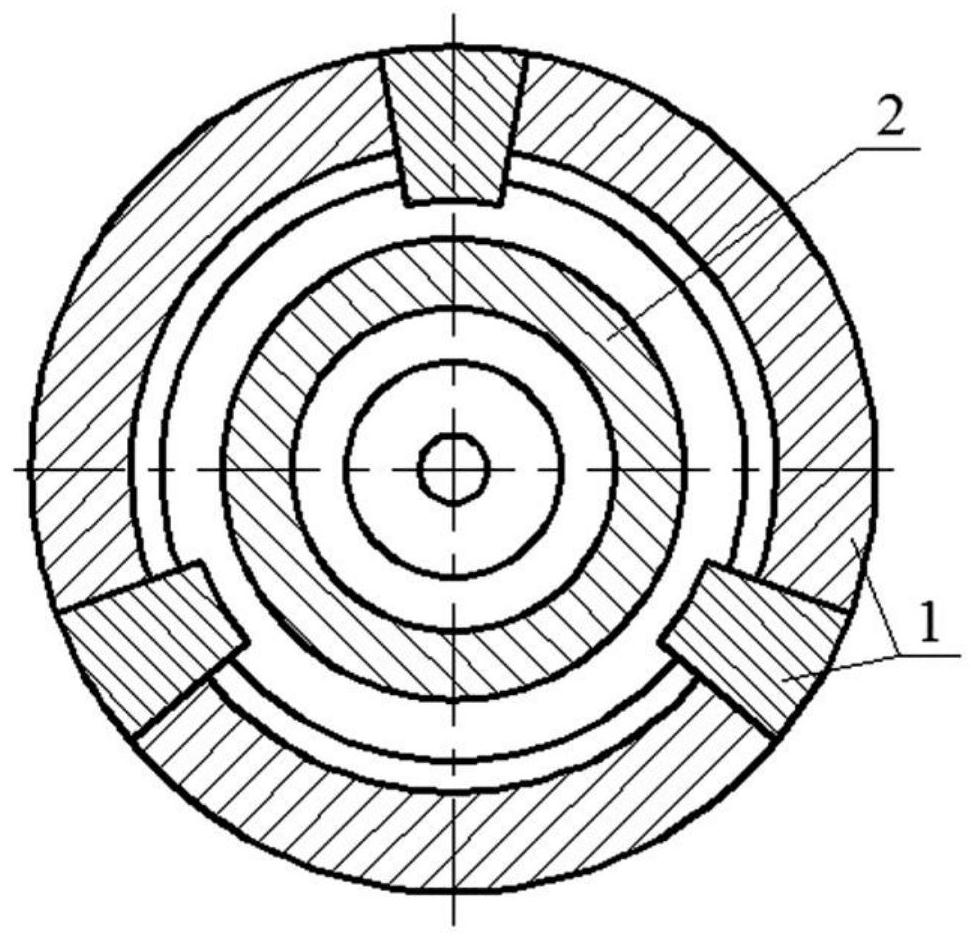

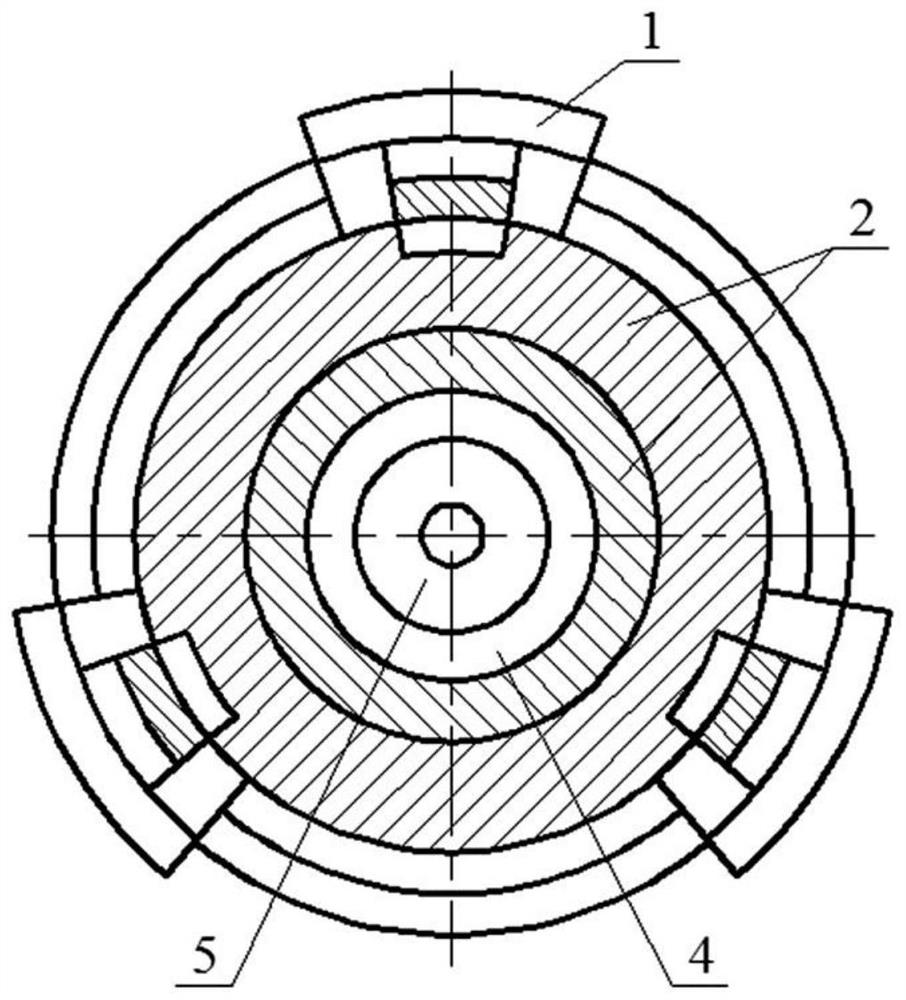

[0042] exist Figure 1 ~ 3 In the middle, the elastic bump step-by-step axial extrusion throttle is composed of a ferrous locking body 1, a throttling body 2, a double sealing capsule 3, an elastic booster 4, and a tapered glower 5. The throttle device achieves the downhole rapid sitting and salvage by the kaisher locking body 1, complete the sealing and unsapping of the seat by the double sealing rubber 3 and the elastic booster 4, and combined with the tapered throttle 5 and the throttle body 2 form a stable throttle field to effectively solve the routine gas well and the well-defined problem of well-defined wells, and prevent the natural gas hydrate from the underlying process.

[0043] exist Figure 1 ~ 3 In the middle, the elastic bump step-by-step axial squeezing the throttling device is fixed to the tube wall of the tube post, and the boosted matrix of the elastic booster 4 Connect with the downhole screen, the kaisha locking body 1, the throttle body 2 and the elastic booste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com