Dustproof heat dissipation mechanism and multifunctional high-voltage power distribution cabinet for new energy automobile

A technology of heat dissipation mechanism and dustproof, applied in substation/distribution device casing, electrical components, substation/switch layout details, etc., can solve the problems of poor cooling effect and easy blocking of dustproof meshes, so as to avoid blockage. , Good dustproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

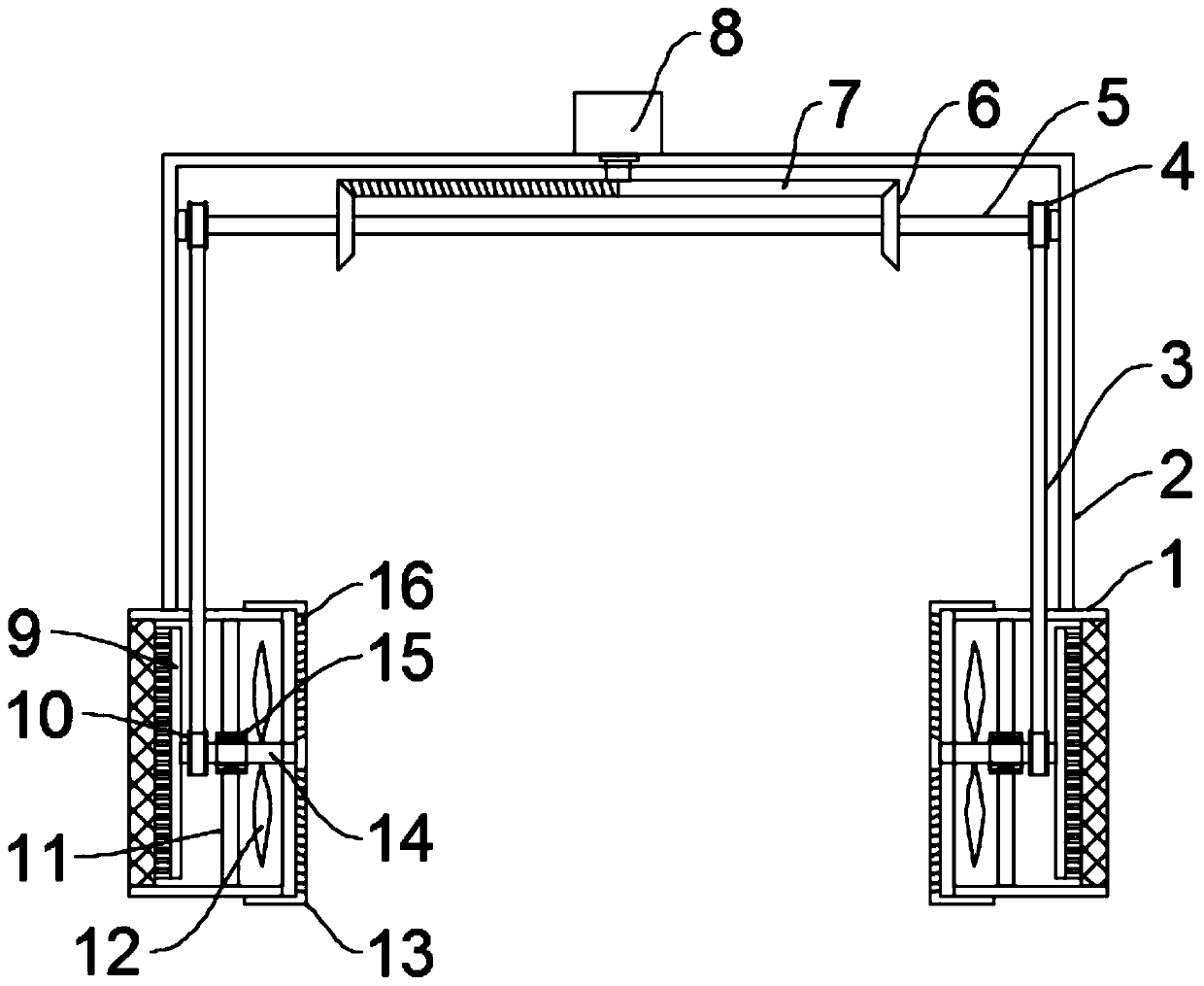

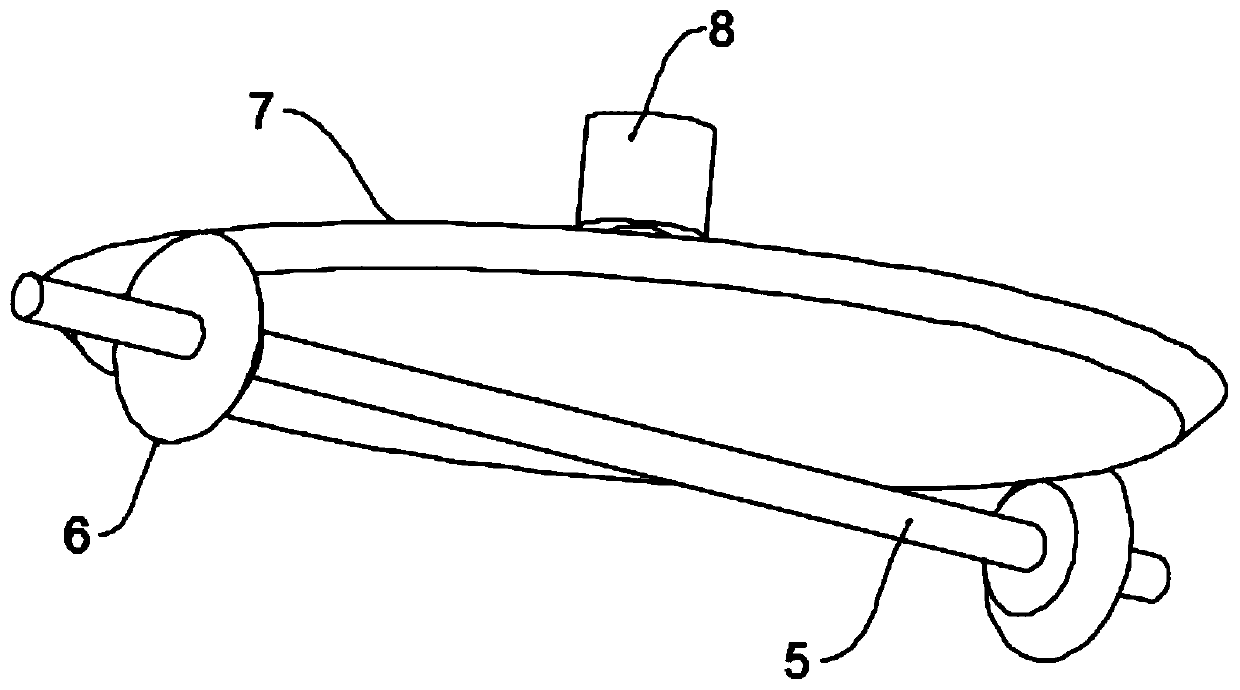

[0021] see Figure 1-2 , in an embodiment of the present invention, a dust-proof heat dissipation mechanism, including a portal frame 2, an installation cylinder 1 and fan blades 12, the installation cylinder 1 is installed on both sides of the bottom of the portal frame 2, and the installation cylinder 1 is installed There are fan blades 12, a motor 8 is installed in the middle of the portal frame 2 top, a semi-conical gear 7 is installed on the output shaft of the motor 8, and a rotating shaft 5 is installed below the semi-conical gear 7 on the portal frame 2, and the rotating shaft 5 passes through the bearing and Portal frame 2 is rotationally connected, bevel gear 6 is installed on both sides of half bevel gear 7 on the rotating shaft 5, the diameter of half bevel gear 7 is at least 10 times of the diameter of bevel gear 6, bevel gear 6 meshes with half bevel gear 7, The outer side of the installation cylinder 1 is equipped with a dust-proof net, the installation cylinder...

Embodiment 2

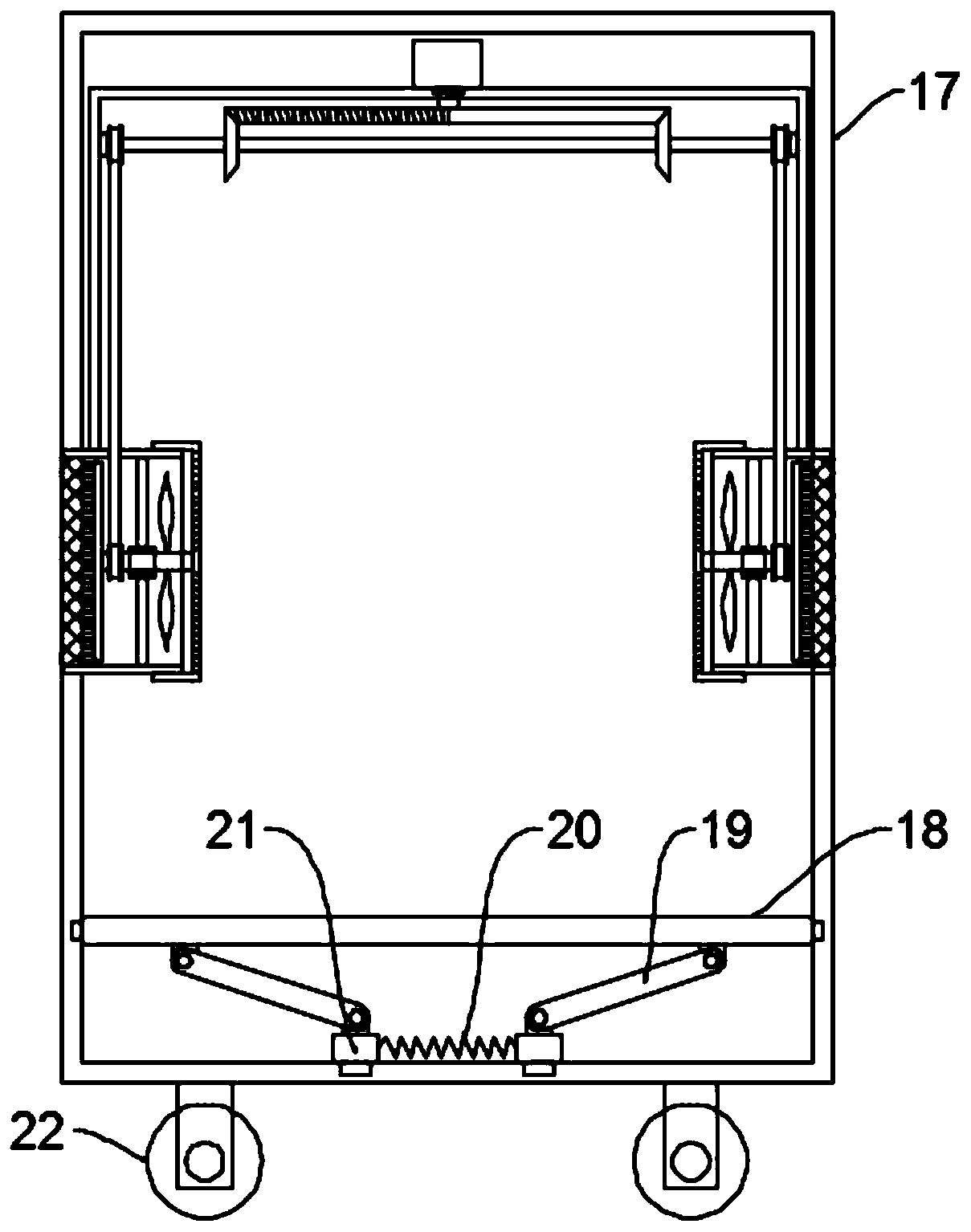

[0023] see image 3 , a multifunctional high-voltage power distribution cabinet for new energy vehicles, including the dust-proof heat dissipation mechanism described in Embodiment 1, and also includes a cabinet body 17 and a shock absorbing device, and the dust-proof heat dissipation mechanism is installed on the cabinet body 17 Inside, the four corners of the bottom of the cabinet body 17 are equipped with rollers 22. The rollers 22 are self-locking rollers to facilitate the movement of the device. Plate 18, connecting rod 19, movable block 21 and damping spring 20, the first slide block is fixed on both sides of described mounting plate 18, and the first slide block is slidingly connected with the inner wall of cabinet body 17, and both sides of mounting plate 18 bottom are all hinged There is a connecting rod 19, the other end of the connecting rod 19 is inclined towards the middle part of the mounting plate 18 and is hinged with a movable block 21, the bottom of the movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com