A Stator Modular Ring Winding Double Rotor Permanent Magnet Motor

A technology of ring winding and permanent magnet motors, which is applied in the shape/style/structure of winding conductors, magnetic circuits, electromechanical devices, etc., and can solve the problems of ineffective use of the space at the end of the motor, increased copper wire consumption, and increased copper consumption of the motor, etc. problems, to simplify the processing and distribution process, facilitate mass production, and improve torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

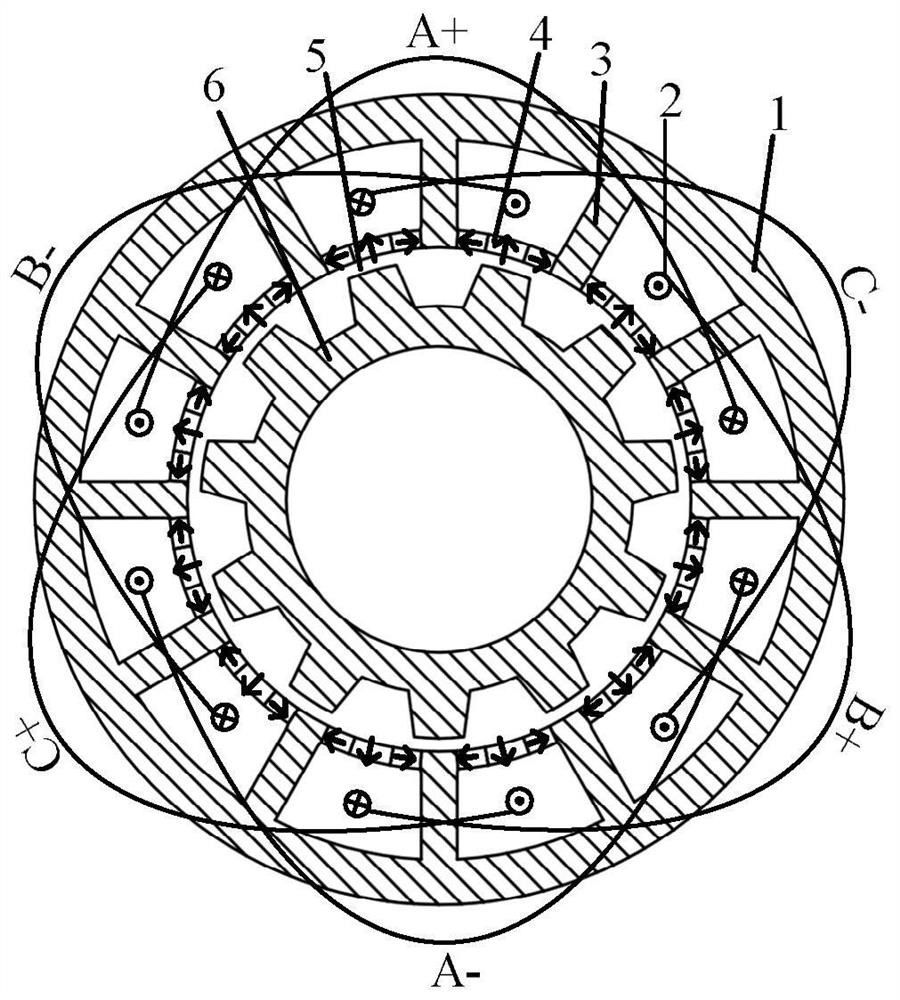

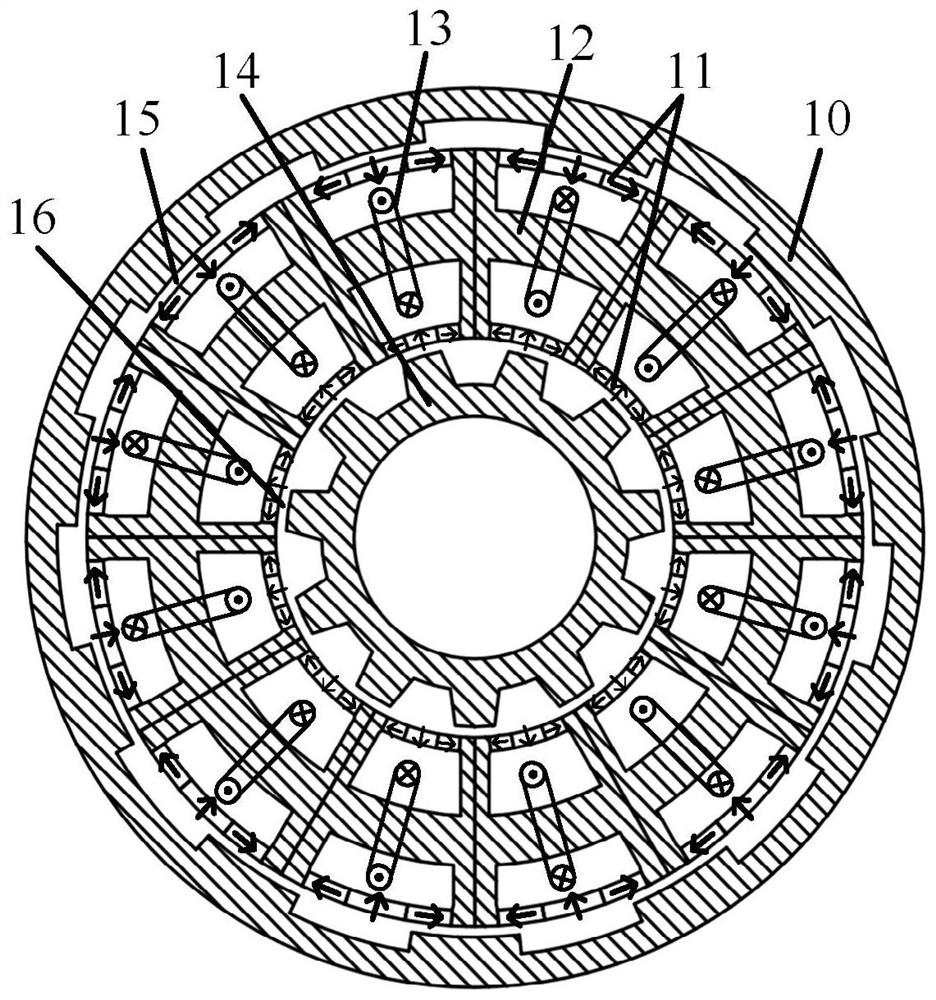

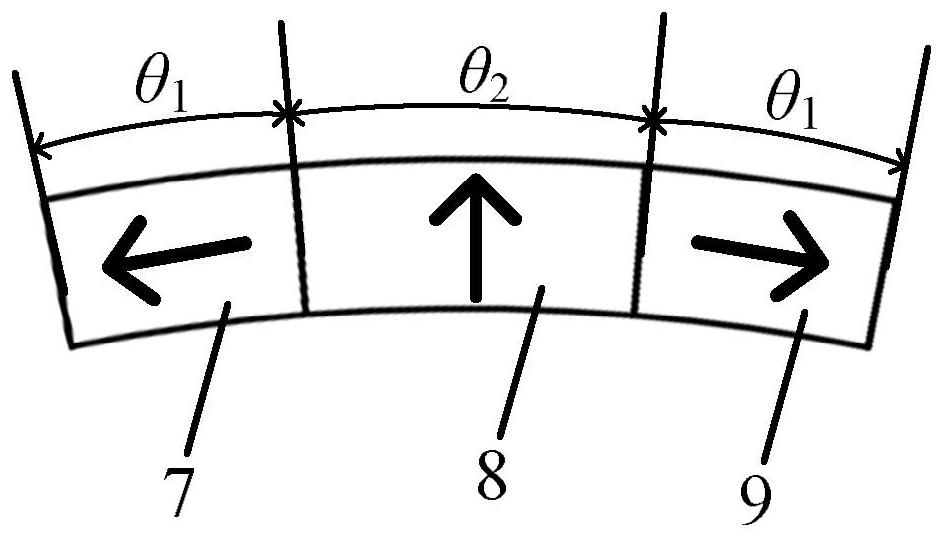

[0030] Such as figure 2 As shown, the structure of Embodiment 1 of the present invention includes an inner rotor 14, an outer rotor 10, and several modular stators 12, and all the modular stators are sequentially spliced according to the circumferential direction to form a complete stator, and the stator is located between the inner rotor 14 and the Between the outer rotor 10, and the inner rotor 14 and the outer rotor 10 respectively form independent air gaps 16 and 15 with the stator. Each modular stator has an inner stator slot and an outer stator slot in the radial direction, the inner stator slot is close to the inner rotor, the outer stator slot is close to the outer rotor, the stator teeth are on both sides of the stator slot, and the space between the inner stator slot and the outer stator slot is It is the stator yoke, and the stator yoke of each modular stator has an armature winding 13 wound in a ring, and permanent magnets 11 are arranged at the slots of the inn...

Embodiment 2

[0040] Such as Figure 9 As shown, the difference between this embodiment and Embodiment 1 lies in the modular stator, since the stator is spliced by discrete modular stators, which affects the reliability of the motor operation. Therefore, in this embodiment, a dovetail slot 31 is provided at the junction of the modularized stators to fix the adjacent stator modules and increase the reliability of the entire motor system. . Other structures of the motor of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com