Manufacturing method of mobile phone backboard with metal color

A manufacturing method and metallic color technology, applied in the structure of telephones, telephone communications, electrical components, etc., can solve the problems of affecting signal reception and transmission, high manufacturing cost of glass plates, and easy yellowing of adhesives, so as to increase transmission and receiving strength, suitable color and easy application method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

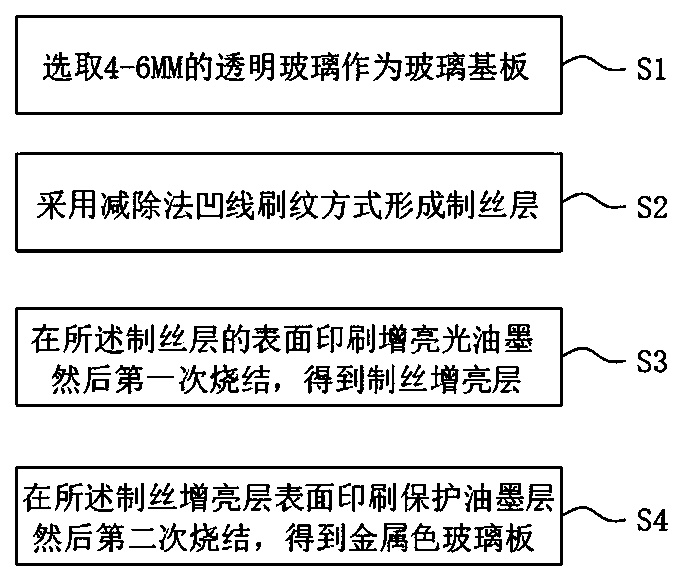

[0024] see figure 1 , the present invention provides the following technical solutions: a method for manufacturing a mobile phone backplane with a metallic color, comprising the following steps:

[0025] S1. Select 4-6mm transparent glass as the glass substrate;

[0026] S2. Forming the silk-making layer by means of the subtractive method of concave line brushing;

[0027] S3, printing brightening ink on the surface of the silk-making layer, and then sintering for the first time to obtain the silk-making brightening layer;

[0028] S4. Printing a protective ink layer on the surface of the fiber-made brightening layer, and then sintering for the second time to obtain a metallic glass plate.

[0029] In this embodiment, the transparent glass of 4-6 mm is selected as the glass substrate; the silk layer is formed by the method of subtraction method concave line brush pattern, and the method of subtraction method concave line brush pattern is that the equipment is adjusted by 200...

Embodiment 2

[0037] see figure 1 , the present invention provides the following technical solutions: a method for manufacturing a mobile phone backplane with a metallic color, comprising the following steps:

[0038] S1. Select 4-6mm transparent glass as the glass substrate;

[0039] S2. Forming the silk-making layer by means of the subtractive method of concave line brushing;

[0040] S3, printing brightening ink on the surface of the silk-making layer, and then sintering for the first time to obtain the silk-making brightening layer;

[0041] S4. Printing a protective ink layer on the surface of the fiber-made brightening layer, and then sintering for the second time to obtain a metallic glass plate.

[0042] In this embodiment, the transparent glass of 4-6 mm is selected as the glass substrate; the silk layer is formed by the method of subtraction method concave line brush pattern, and the method of subtraction method is the adjustment of the equipment through the pressure of 500 Pa a...

Embodiment 3

[0050] see figure 1 , the present invention provides the following technical solutions: a method for manufacturing a mobile phone backplane with a metallic color, comprising the following steps:

[0051] S1. Select 4-6mm transparent glass as the glass substrate;

[0052] S2. Forming the silk-making layer by means of the subtractive method of concave line brushing;

[0053] S3, printing brightening ink on the surface of the silk-making layer, and then sintering for the first time to obtain the silk-making brightening layer;

[0054] S4. Printing a protective ink layer on the surface of the fiber-made brightening layer, and then sintering for the second time to obtain a metallic glass plate.

[0055] In this embodiment, the transparent glass of 4-6 mm is selected as the glass substrate; the fiber-making layer is formed by the method of subtraction method concave line brush pattern, and the method of subtraction method concave line brush pattern is that the equipment is adjuste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com