High-temperature and high-pressure supercritical carbon dioxide reaction kettle

A technology of carbon dioxide, high temperature and high pressure, applied in chemical/physical/physical chemical fixed reactors, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as poor sealing effect of reactors, achieve high degree of automation, Timely monitoring of pressure conditions and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

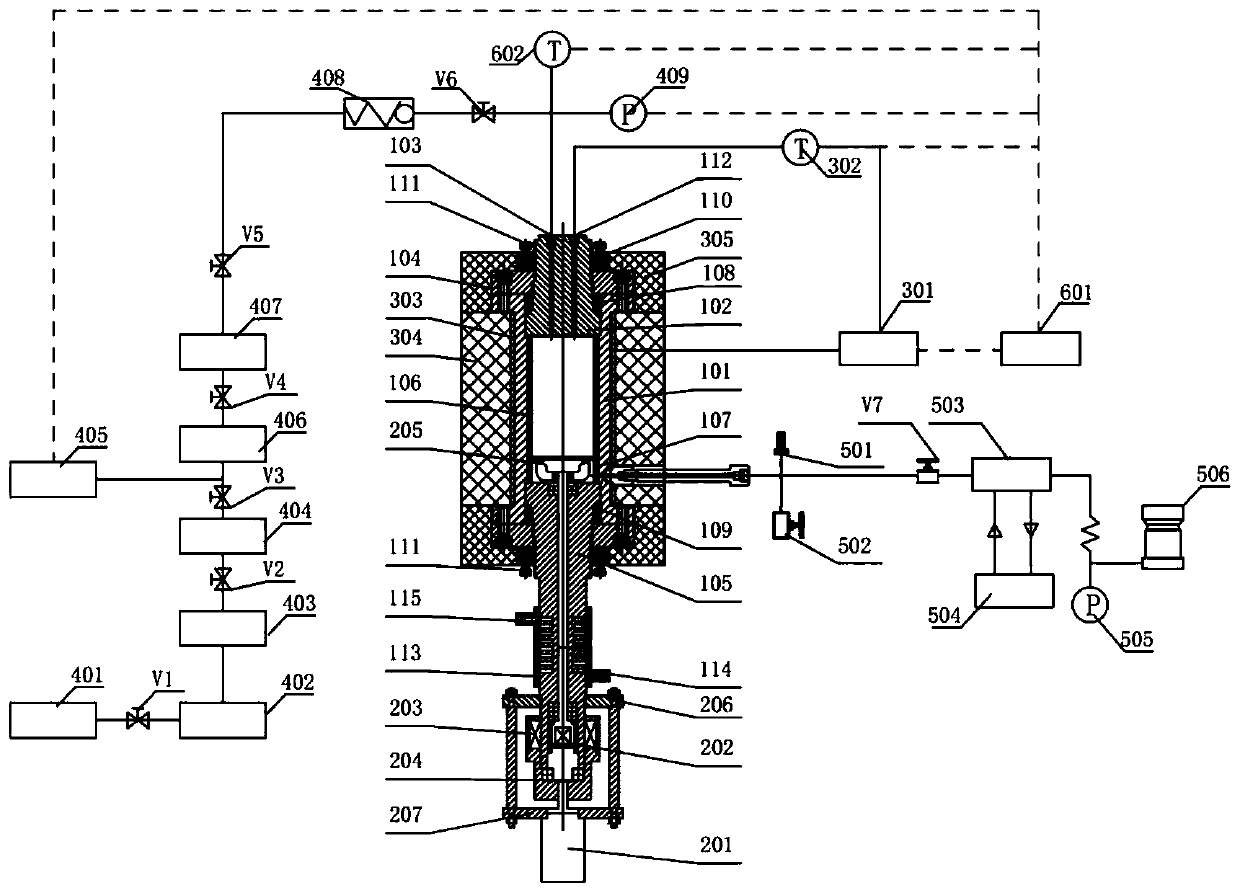

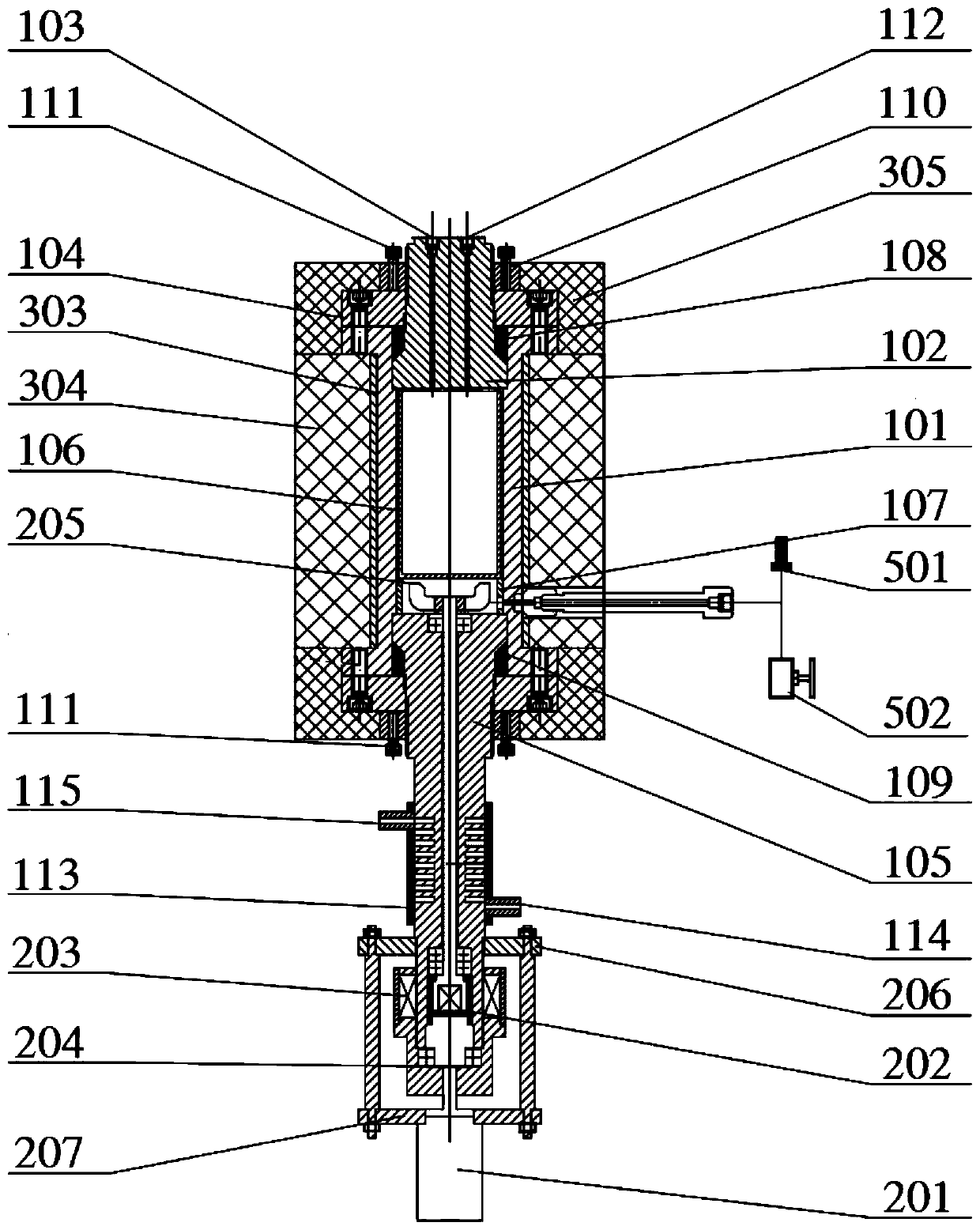

[0025] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0026] The present invention aims at the unsatisfactory high-temperature resistance performance of the existing reactors in the face of supercritical carbon dioxide reaction as a whole, and it is not easy to maintain a high temperature and high pressure state all the time. At the same time, it is difficult to achieve real-time monitoring and control of the temperature and pressure state in the reactor during the reaction. , the reaction efficiency is low, and the sealing effect of the reactor is not good, and a high-temperature and high-pressure supercritical carbon dioxide reactor is provided.

[0027] Such as figure 1As shown, the embodiment of the present invention provides a high temperature and high pressure supercritical carbon dioxide reactor, com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com