Composite rim manufacturing method and structure

A composite, rim-based technology, applied to other household appliances, household appliances, household components, etc., can solve problems such as troublesome and time-consuming construction, poor combination of carbon fiber rims and tires, and air leakage, etc., to improve safety performance and durability, improving production efficiency and yield, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical means of the present invention and the effects it can achieve more completely and clearly disclosed, the detailed description is as follows, please refer to the disclosed drawings and figure numbers:

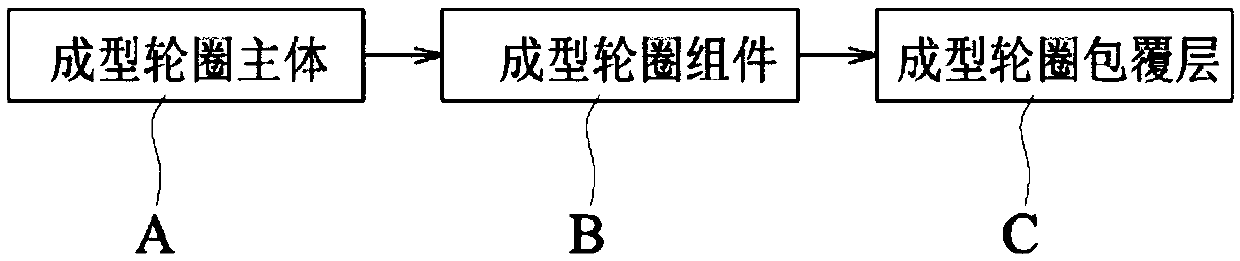

[0043] First, see figure 1 , figure 2 Shown, be the composite rim method of the present invention, its main implementation steps include:

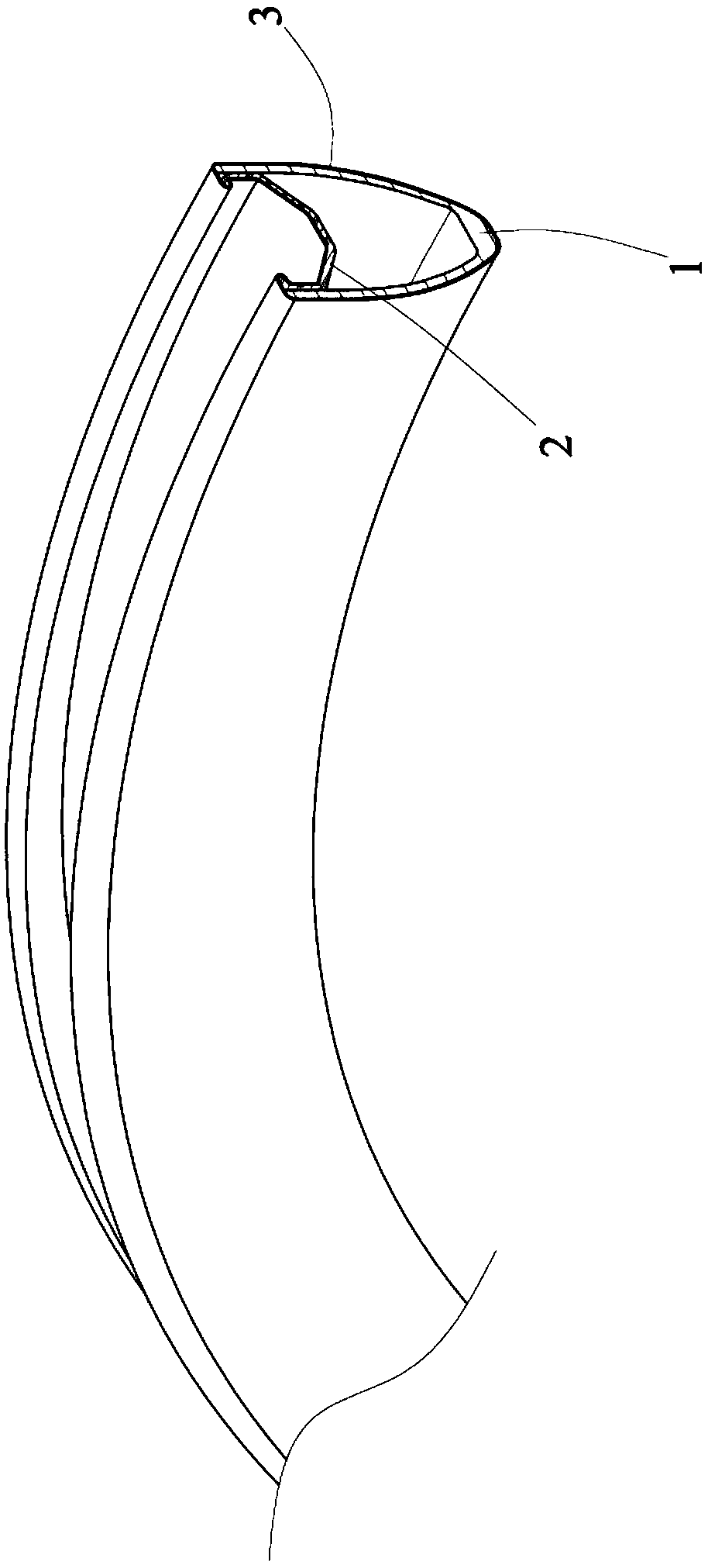

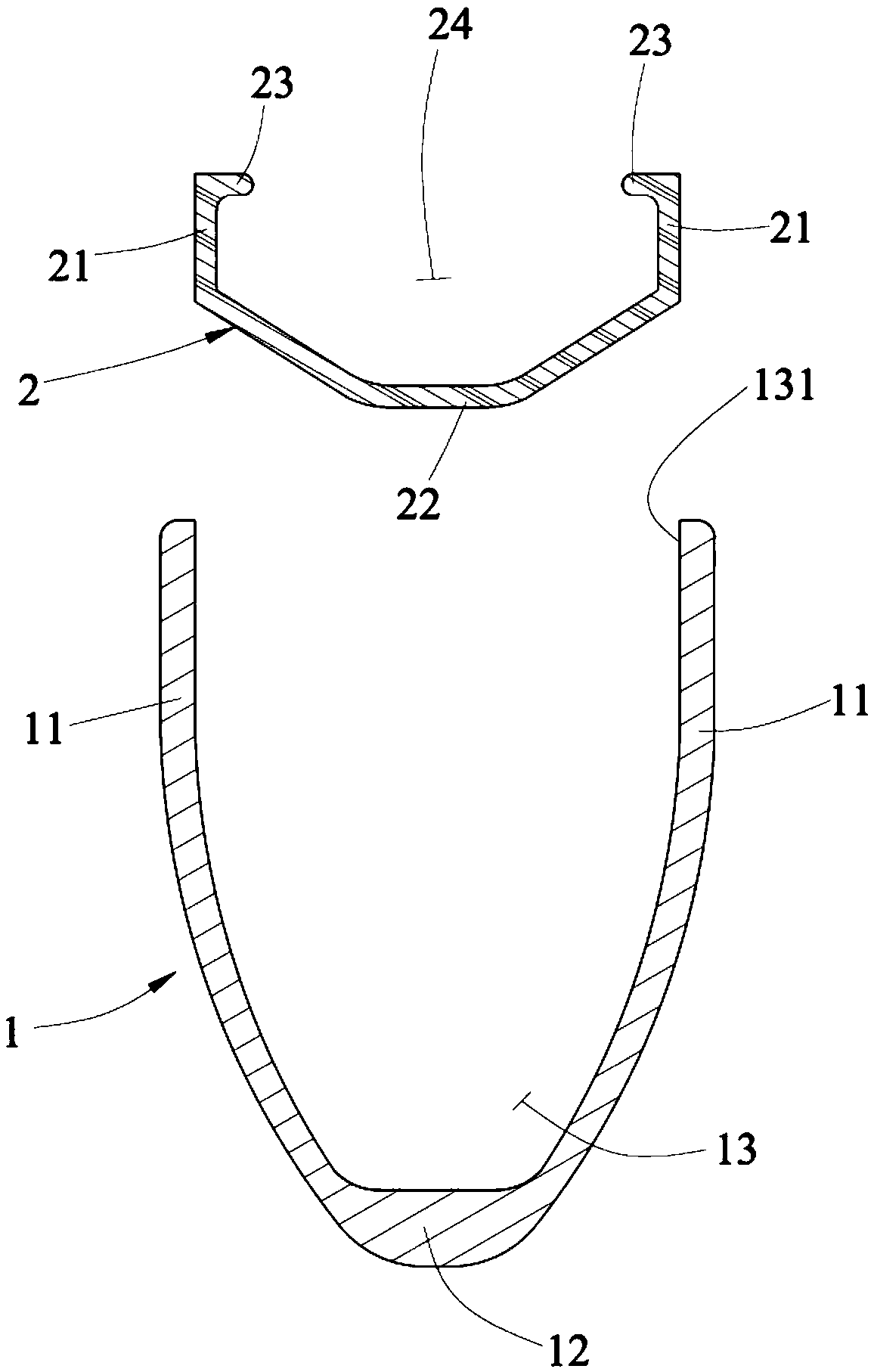

[0044] A. Forming the main body of the rim: prepare a rim main body molding mold, and a mold cavity is provided in the rim main body molding mold, and multiple layers are sequentially pasted along the cavity wall of the rim main body molding mold The first carbon fiber material, the first carbon fiber material can be carbon fiber cloth material, and then the first carbon fiber material is heated and hardened in the rim body forming mold to form a ring-shaped rim body 1, please see also image 3 As shown, the section of the rim main body 1 is formed with two opposite side walls 11 and a bottom wall 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com