Preparation method for producing arene and olefin from mixed alcohol

A technology for olefins and aromatic hydrocarbons, which is applied in the field of preparing aromatic hydrocarbons and olefins with mixed alcohols, can solve problems such as outstanding environmental protection problems, difficult water separation, and high energy consumption, and achieves the advantages of saving production costs, reducing energy consumption, and reducing environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

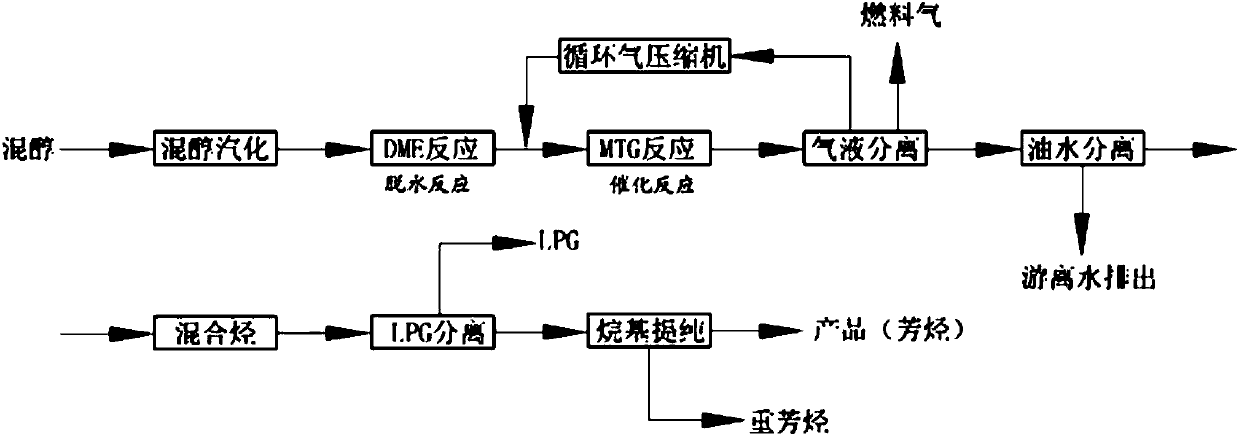

[0025] This example provides a preparation method for producing aromatics and olefins with mixed alcohol, which includes the following steps: (1) vaporization treatment, (2) first dehydration reaction, (3) second Dehydration reaction, (4) gas-liquid separation, (5) oil-water separation, (6) LPG separation and (7) alkyl purification.

[0026] The mixed alcohol in this embodiment includes the following components in mass percentage: 15% methanol, 45% ethanol, 7% other miscellaneous alcohols, and the balance is water.

[0027] Firstly, the mixed alcohol is subjected to (1) vaporization treatment, the purpose is to turn all the mixed alcohol into gas, that is, to heat the mixed alcohol to vaporize, the heating temperature is 200°, and the vaporization pressure is 1.4Mpa.

[0028] The gas obtained by the vaporization of step (1) is processed in step (2), and step (2) is the first dehydration reaction, and the first dehydration reaction is that the temperature and pressure of the va...

Embodiment 2

[0056] This example provides a preparation method for producing aromatics and olefins with mixed alcohols, which includes the following steps: (1) vaporization treatment of mixed alcohols, (2) first dehydration reaction, (3) second Dehydration reaction, (4) gas-liquid separation, (5) oil-water separation, (6) LPG separation and (7) alkyl purification.

[0057] The mixed alcohol of the present embodiment comprises the following components in mass percentage: methanol 10%, ethanol 50%, and the balance is water.

[0058] Firstly, the mixed alcohol is subjected to (1) vaporization treatment, the purpose is to turn all the mixed alcohol into gas, that is, to heat the mixed alcohol to vaporize, the heating temperature is 180°, and the vaporization pressure is 1.4Mpa.

[0059] The gas obtained by the vaporization of step (1) is processed in step (2), and step (2) is the first dehydration reaction. Mix with dimethyl ether catalyst under Mpa, the volume ratio of the volume of describe...

Embodiment 3

[0068] This example provides a preparation method for producing aromatics and olefins with mixed alcohols, which includes the following steps: (1) vaporization treatment of mixed alcohols, (2) first dehydration reaction, (3) second Dehydration reaction, (4) gas-liquid separation, (5) oil-water separation, (6) LPG separation and (7) alkyl purification.

[0069] The mixed alcohol of this embodiment comprises the following components in mass percentage: 20% of methanol, 40% of ethanol, 10% of other fusel alcohols, and the balance is water.

[0070] First, the mixed alcohol is subjected to (1) vaporization treatment, the purpose is to turn all the mixed alcohol into gas, that is, to heat the mixed alcohol to vaporize, the heating temperature is 230°, and the vaporization pressure is 1.4Mpa.

[0071] The gas obtained by the vaporization of step (1) is processed in step (2), and step (2) is the first dehydration reaction. Mix with dimethyl ether catalyst under Mpa, the volume ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com