Pentaerythritol ester lubricating oil base oil and preparation method thereof

A technology of lubricating base oil and pentaerythritol ester is applied in the field of lubricating base oil, which can solve the problems of low viscosity-temperature and high-temperature oxidation stability, and achieve the effect of excellent viscosity-temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

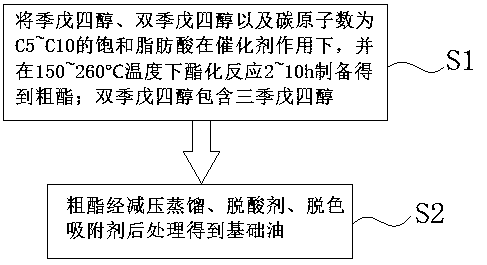

Method used

Image

Examples

Embodiment 4

[0049] In Example 4: the various indicators of the base oil are as follows: the kinematic viscosities at 40°C, 100°C, and -40°C are respectively 23.0mm 2 / s, 4.78mm 2 / s, 8500mm 2 / s, the viscosity index is 132, and the pour point is lower than -60°C.

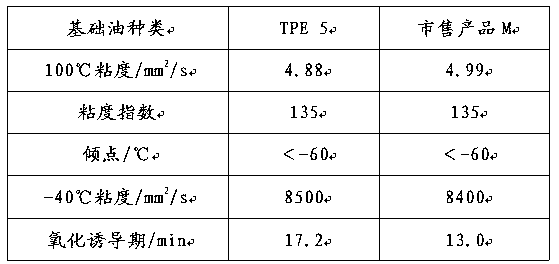

[0050] In combination with the above-mentioned scheme, specifically, as this Example 5: base oil is prepared according to the method of Example 1, the difference is that the ratio of raw materials added is different; take 31.0g of pentaerythritol (purity 90%), 5.0g of dipentaerythritol (purity 90%) , of which tripentaerythritol is about 1.5g, the mass fraction is 4.1%, and the total number of hydroxyl groups is about 1.06mol. According to the ratio of carboxyl / hydroxyl molar excess ratio of about 3%, n-valeric acid, n-octanoic acid, n-nonanoic acid, and 2-methylbutyric acid , 2-methylvaleric acid 20.5g, 37.5g, 31.5g, 12.2g, 37.0g, the molar ratio of each acid is 23.6%, 18.2%, 18.2%, 11%, 29%, normal carboxyl, iso The ratios ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com