Mixed bullet belt device containing pre-set carving grooves

A belt and preset technology, applied in the direction of ammunition supply, offensive equipment, weapon accessories, etc., can solve the problems of small expansion effect of metal belt materials, contact collision, gunpowder gas leakage, etc., to improve air-holding performance and reduce collision damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

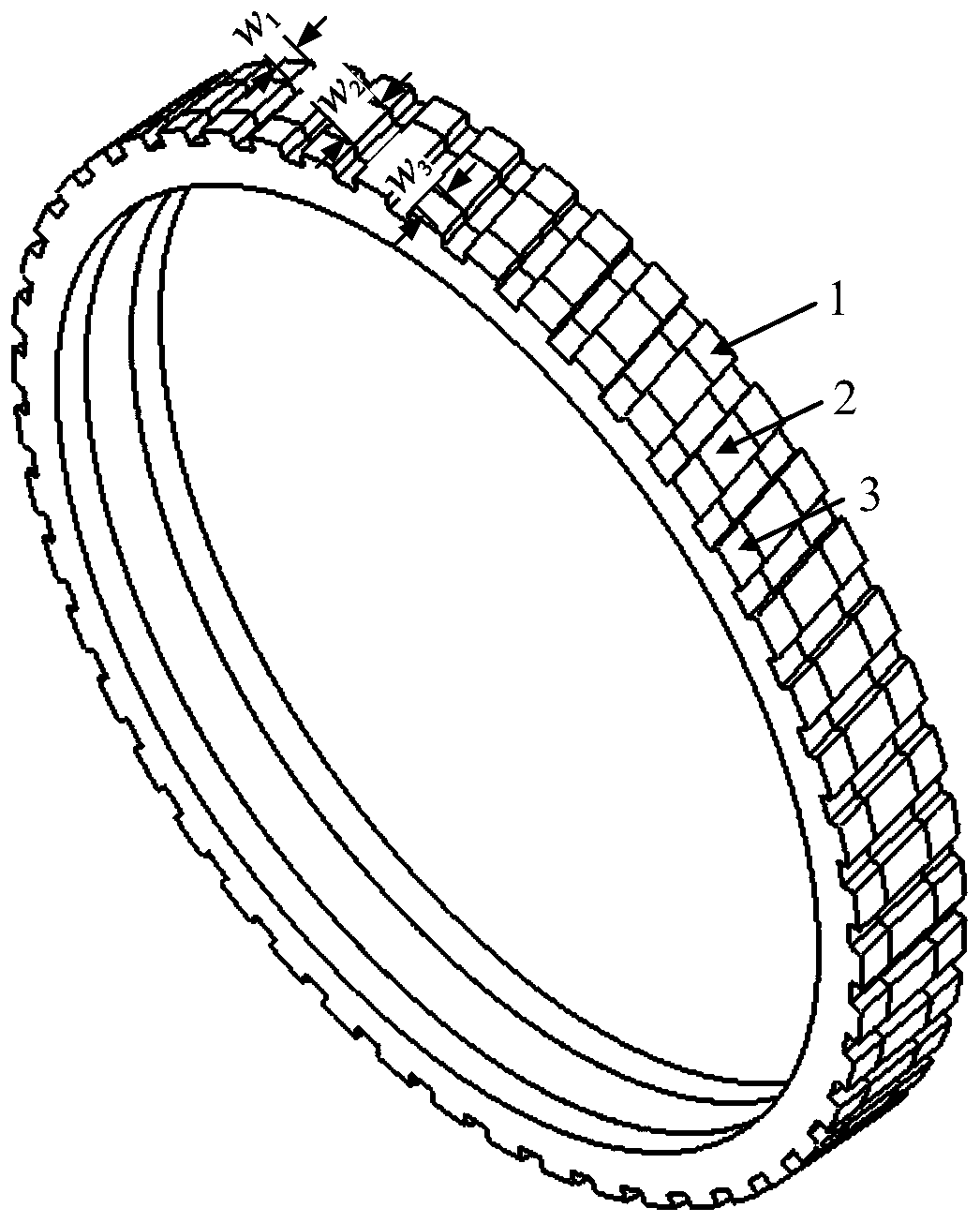

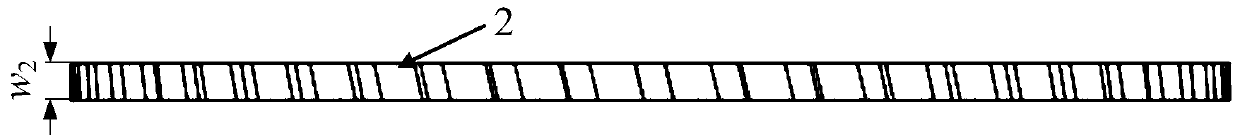

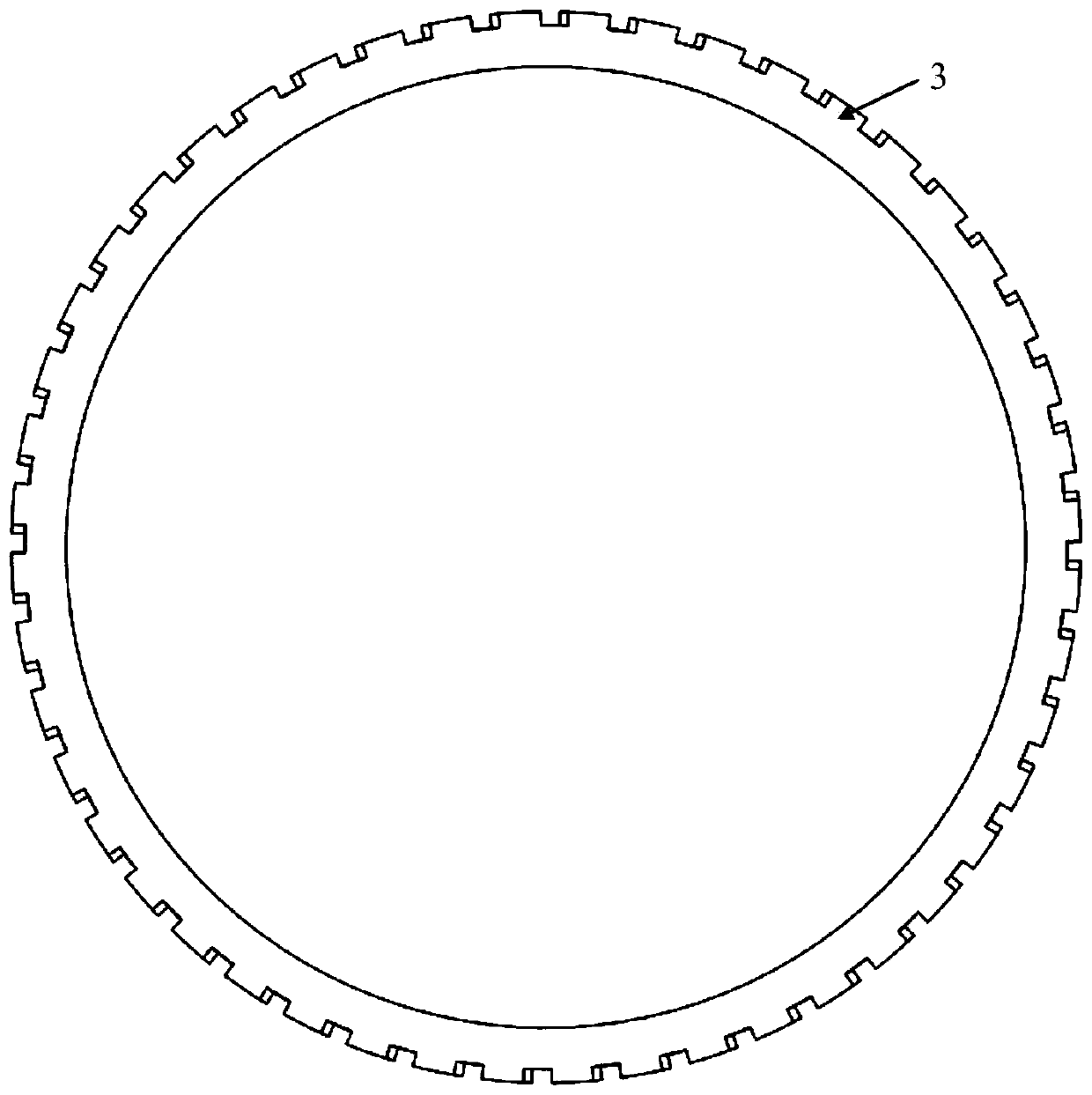

[0019] The invention proposes a hybrid elastic belt device with preset notches, which includes two plastic elastic belt rings and one metal elastic belt ring.

[0020] The present invention uses thermal conductivity greater than 0.2W·m -1 ·K -1 and coefficient of thermal expansion greater than 1.0×10 -4 K -1 Plastics (such as polytetrafluoroethylene) are used to make the plastic belts on both sides of the hybrid belt, and the middle belt ring is made of metal (such as copper or copper alloy). By using the thermal expansion characteristics of the belt ring on the bottom side of the bomb, the air-holding performance of the launch system is enhanced to a certain extent; the material rigidity of the plastic belt ring is used to slow down the impact on the inner wall of the barrel caused by the impact and collision between the belt and the barrel Damage; Utili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com