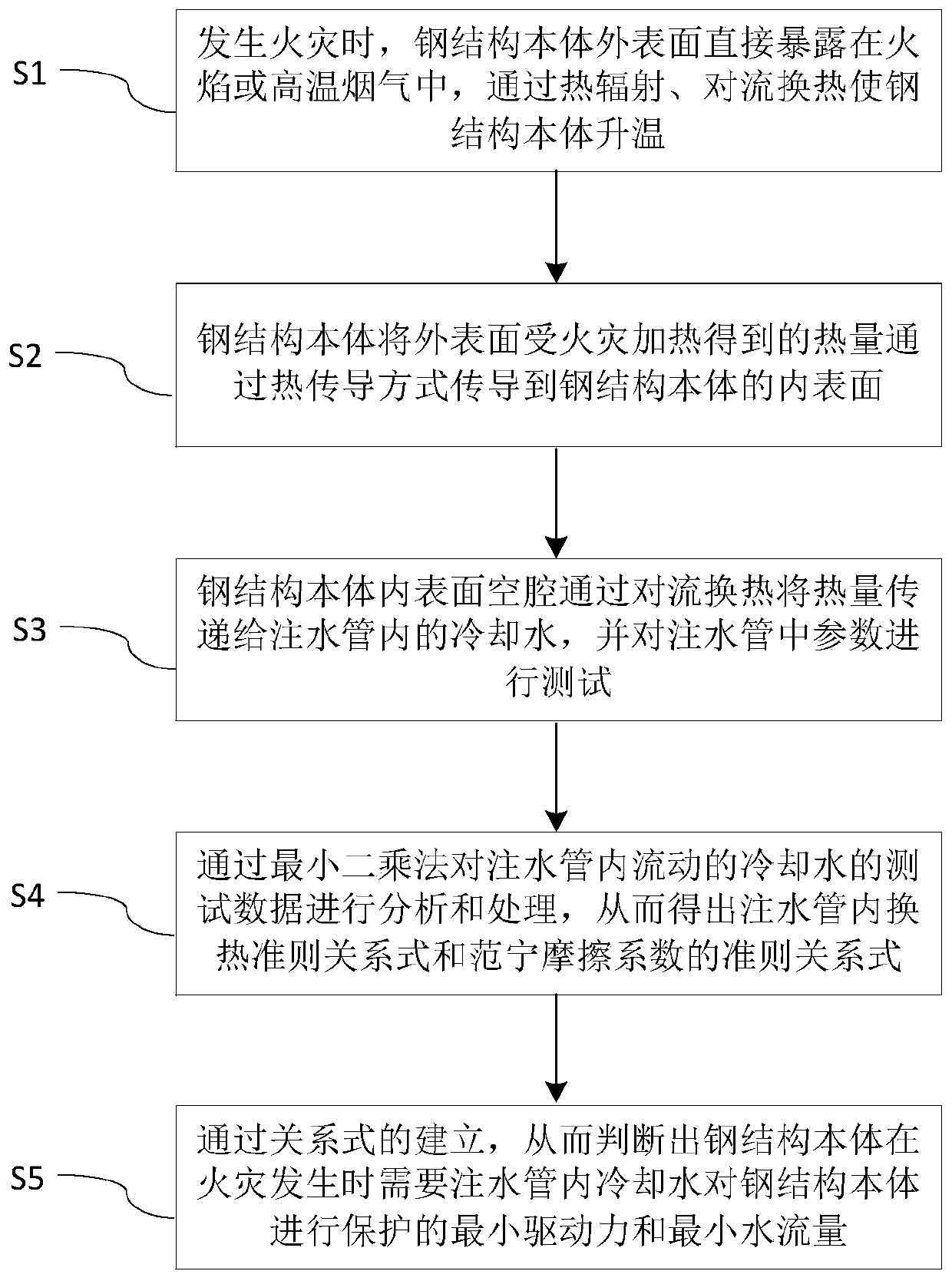

Steel structure water injection fireproof protection method

A technology for steel structures and water injection pipes, applied in geometric CAD, computer-aided design, calculation, etc., can solve the problems that fire-resistant coatings cannot protect steel structures, temperature instability, and falling of steel structures, and achieve good fire protection effects and mechanical properties The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

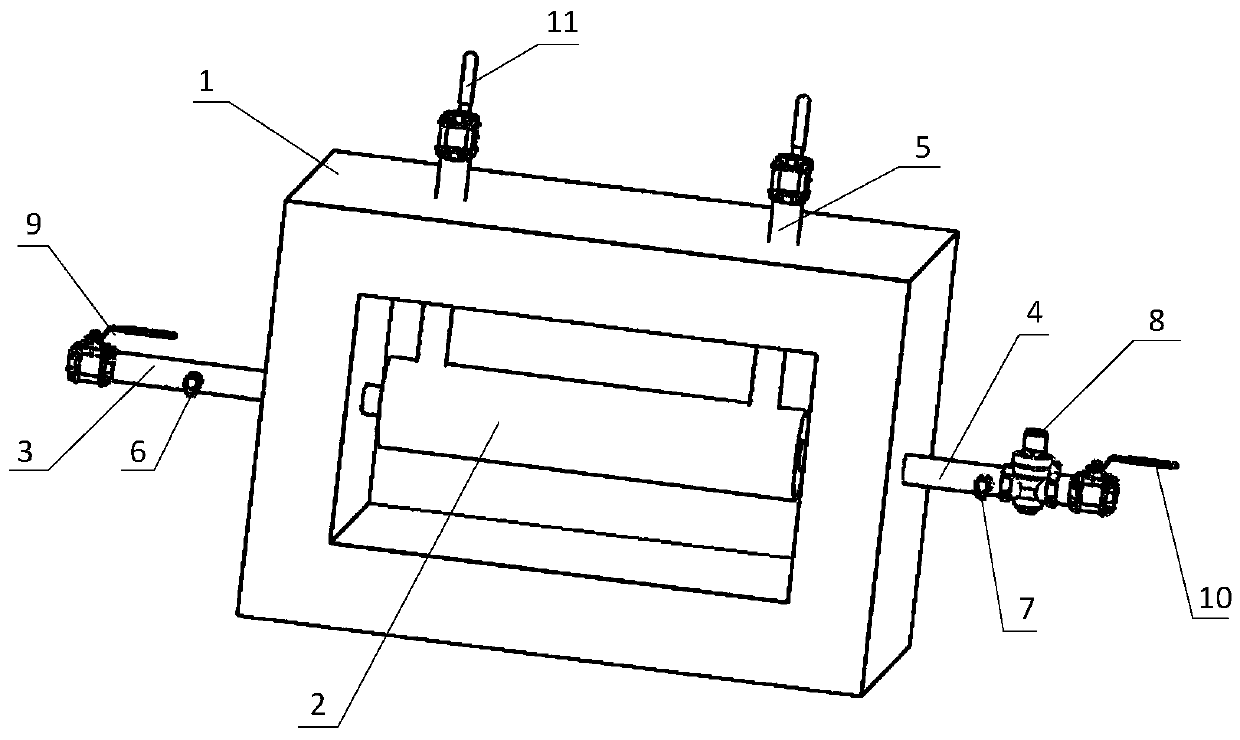

[0048] as per figure 2As shown, the water injection pipe 2 is installed in the steel structure body 1, and then the water inlet pipe 3 and the water outlet pipe 4 are connected to the two ends of the water injection pipe 2 through the steel structure body 1, and the water inlet pipe 3 and the water outlet pipe 4 are installed. The valve 9 and the water outlet valve 10 also need to install the water inlet pressure gauge 6 and the water outlet pressure gauge 7 for detecting the pressure of the cooling water in the pipeline, and additionally need to be installed on the water outlet pipe 4 to measure the pressure from the water injection pipe. 2. Thermocouple gauge 8 of the cooling water temperature discharged. The exhaust pipe 5 that communicates with the water injection pipe 2 is arranged to determine the quantity of the exhaust pipe according to the length of the water injection pipe 2. Usually, an exhaust pipe needs to be provided with an interval of 5 to 8 meters, and the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com