Microphone, preparation method thereof and electronic equipment

A technology of microphone and conductive layer, which is applied in the field of microphone and its preparation, which can solve the problems of film peeling, complicated preparation process of double-back electrode MEMS microphone, and excessive film, so as to reduce the number of film layers and improve the problem of wafer warpage , The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] A preparation method for a double-back pole MEMS microphone, comprising the following steps:

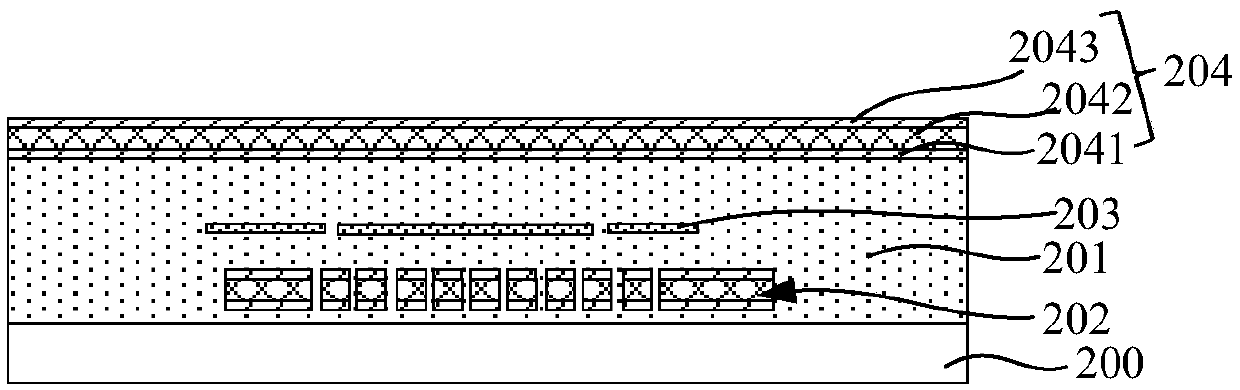

[0058] First, please refer to Figure 1A , providing a substrate formed with a lower back plate 202 and a diaphragm 203, the substrate also includes a base 200 and an insulating layer 201, and the lower back plate 202 has a plurality of holes penetrating through the lower back plate 202 The first through hole 2021, the diaphragm 203 has a plurality of second through holes 2031 penetrating through the diaphragm 203, and the insulating layer 201 connects between the lower back electrode plate 202 and the base 200 and between the lower back electrode plate 202 and the substrate 200 respectively. The diaphragms 203 are separated from each other, and the insulating layer 201 fills the first through hole 2021 and the second through hole 2031 , and completely buries the lower back plate 202 and the diaphragm 203 inside.

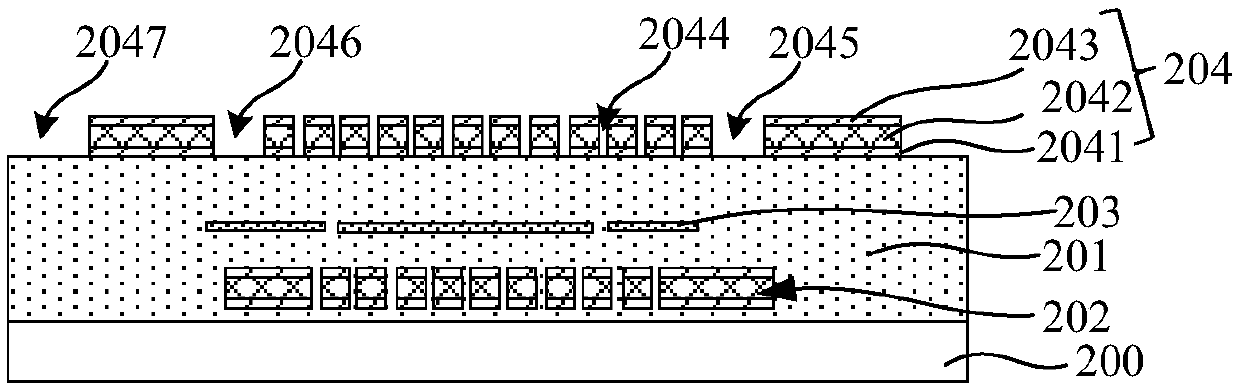

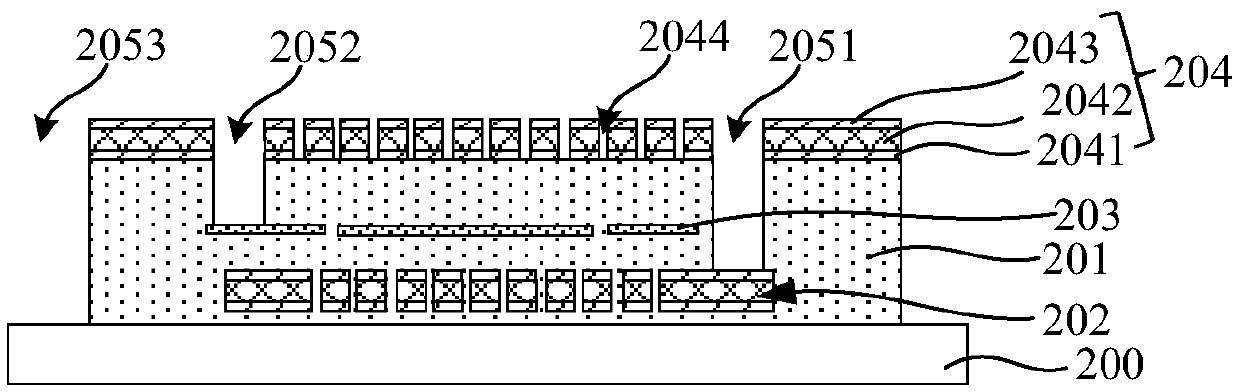

[0059] Next, please refer to Figure 1B , deposit the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com