Efficient catalytic oxidation system based on adsorption and desorption coupling of double-circulating fluidized bed

A catalytic oxidation and fluidized bed technology, which is applied in chemical instruments and methods, gas treatment, and separation of dispersed particles, can solve the problems of large changes in air volume and concentration, difficulty in popularization, and limited range of applicable air volume, etc., to reduce operating costs in the later stage , Avoid installation and operation, and improve operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

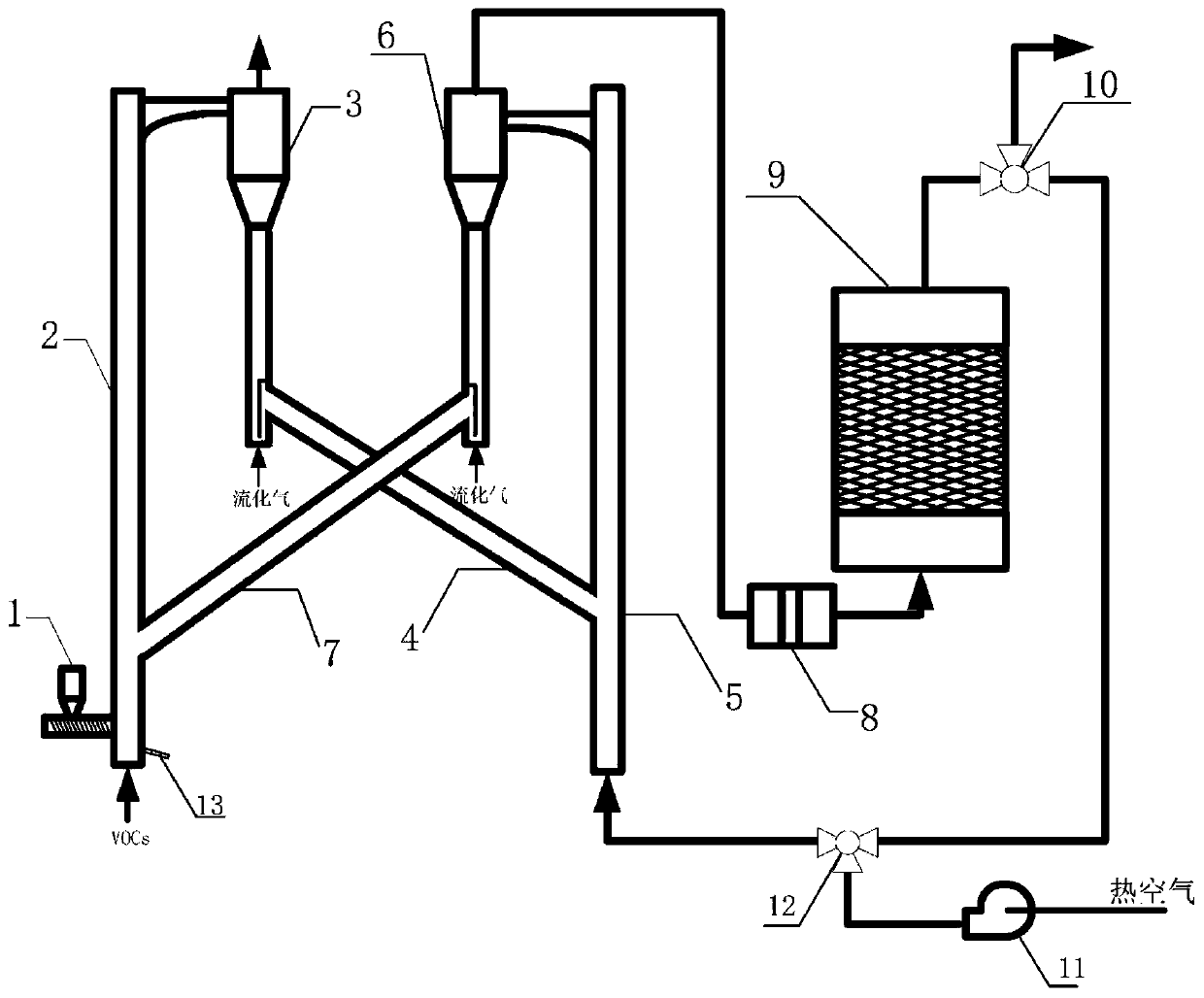

[0044] equipment such as figure 1 As shown, it includes: a screw feeder 1 for adsorption particle feed and a discharge port 13 for adsorption particle discharge; a dual-circulation fluidized bed system for adsorption and desorption, which includes the adsorption of organic waste gas Riser 2, adsorption cyclone separator 3, adsorption return device 4, desorption riser 5, desorption cyclone separator 6, desorption return device 7; a system for catalytic oxidation of organic waste gas, which includes a catalytic oxidation device 9. Empty valve 10; wherein, the screw feeder 1 is connected to the bottom of the adsorption riser 2 (fast fluidized bed); the top of the adsorption riser 2 is connected to the top of the adsorption cyclone separator 3; the adsorption cyclone The bottom of separator 3 links to each other with desorption riser 5 by adsorption feeder 4, and the top of desorption riser 5 (fast fluidized bed) links to each other with the top of desorption cyclone separator 6, ...

Embodiment 2

[0047] When the air volume of the organic waste gas is higher than the design air volume range, the screw feeder 1 is started again, and a given amount of adsorption particles is added to the bottom 2 of the adsorption riser to ensure the contact of the gas-solid phase and the purification efficiency. All the other processes are consistent with Example 1.

Embodiment 3

[0049] When the concentration of organic waste gas is higher than the design concentration range, the screw feeder 1 is started again, and a certain amount of adsorption particles are supplied to the bottom of the adsorption riser to ensure the contact of gas-solid phase and the purification efficiency. At the same time, start the blower 11 to fill in the hot air to ensure that the desorption efficiency of the adsorption particles in the desorption riser 5 is not greatly reduced. All the other processes are consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com