Magnetic adsorption separation device for metal powder waste residues

A metal powder and sorting device technology, which is applied in the directions of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of imperfect adsorption separation, metal ash slag rolling, etc., and achieves the effect of improving the stroke and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

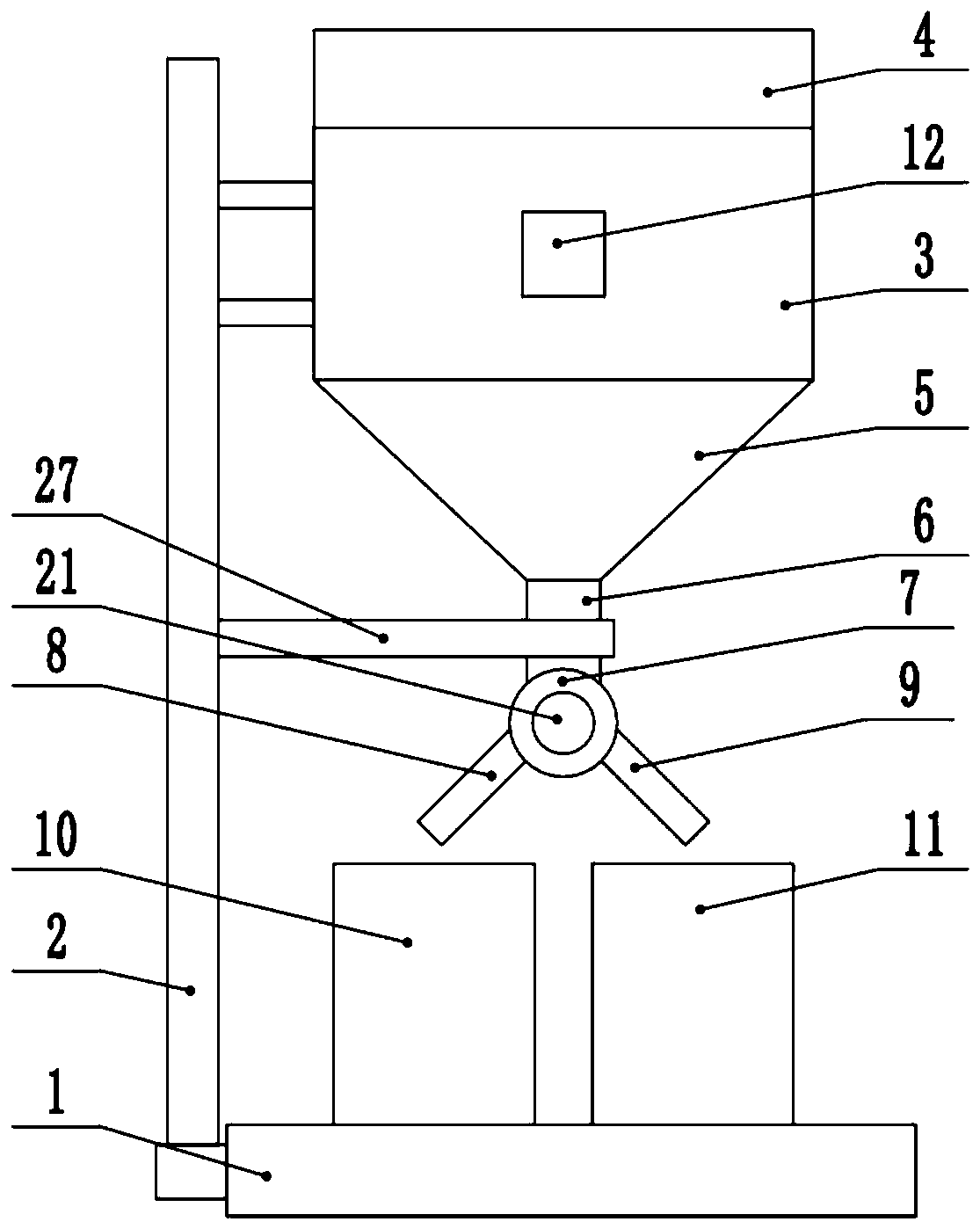

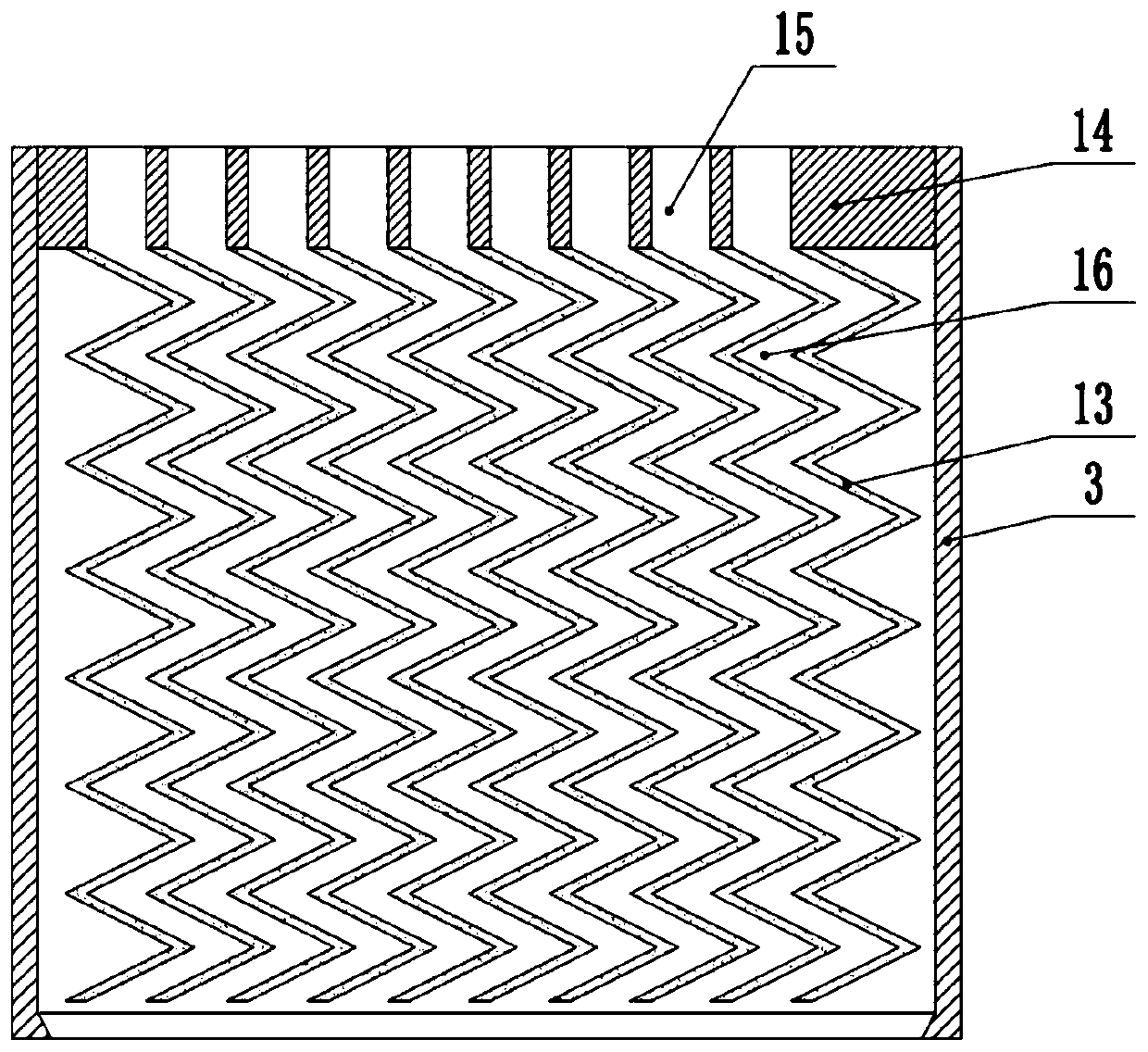

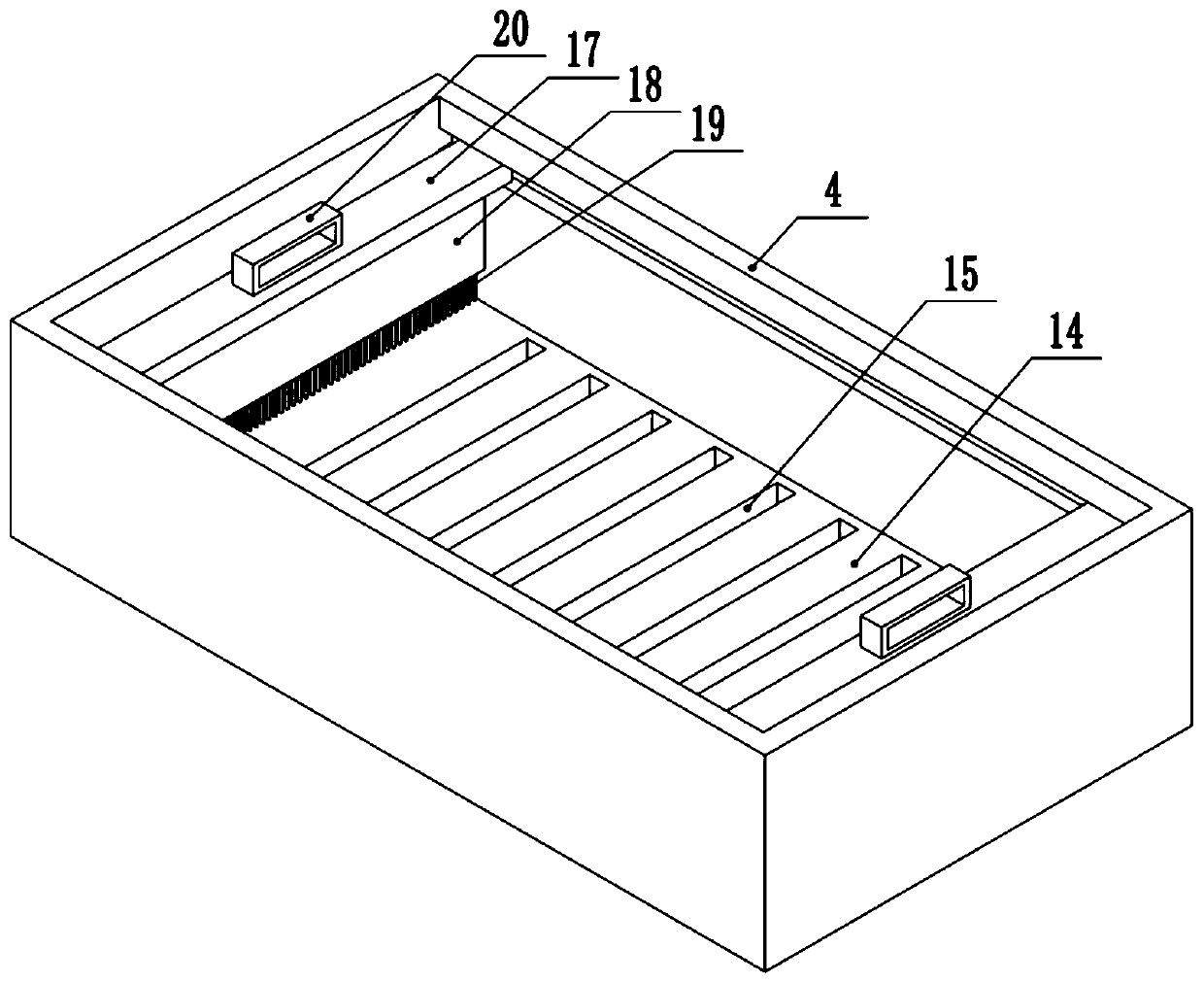

[0026] see Figure 1-4 , a magnetic separation device for metal powder waste slag, comprising a base 1, one end of the base 1 is fixedly connected to a side frame 2, an adsorption cover 3 is arranged above the base 1, the adsorption cover 3 is fixedly connected to the side frame 2, and the adsorption cover 3 is provided with an adsorption separation device, the top of the adsorption cover 3 is fixedly connected to the feed cover 4, and the feed cover 4 is provided with a feeding device, and the bottom end of the adsorption cover 3 is fixedly connected to the collection cover 5, and the collection cover 5 The bottom end of the main pipe 6 is fixedly connected to the feeding main pipe 6, and the bottom end of the feeding main pipe 6 is fixedly connected to the distributing device 7, and the two sides of the distributing device 7 are respectively fixedly connected to the first feeding pipe 8 and the second feeding pipe 9, A first collecting box 10 and a second collecting box 11 c...

Embodiment 2

[0029] see Figure 1-4 , comprising a base 1, one end of the base 1 is fixedly connected to the side frame 2, an adsorption cover 3 is arranged above the base 1, the adsorption cover 3 is fixedly connected to the side frame 2, an adsorption separation device is arranged inside the adsorption cover 3, and the adsorption cover 3 The top of the suction cover 3 is fixedly connected to the feeding cover 4, and a feeding device is provided in the feeding cover 4. The bottom end of the adsorption cover 3 is fixedly connected to the collecting cover 5, and the bottom end of the collecting cover 5 is fixedly connected to the feeding main pipe 6. The bottom end of the material main pipe 6 is fixedly connected with the distribution device 7, and the both sides of the distribution device 7 are respectively fixedly connected with the first feeding pipe 8 and the second feeding pipe 9, and the top of the base 1 is placed with the first The first collection box 10 and the second collection b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com