Extrusion die, device and method for realizing bidirectional extrusion forming process

A forming process and two-way extrusion technology, applied in the direction of metal extrusion dies, etc., can solve the problems of extruders and extrusion dies that have not yet appeared in the two-way extrusion process, improve the stress conditions of the die, prevent the deformation of the punch, The effect of good weld quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

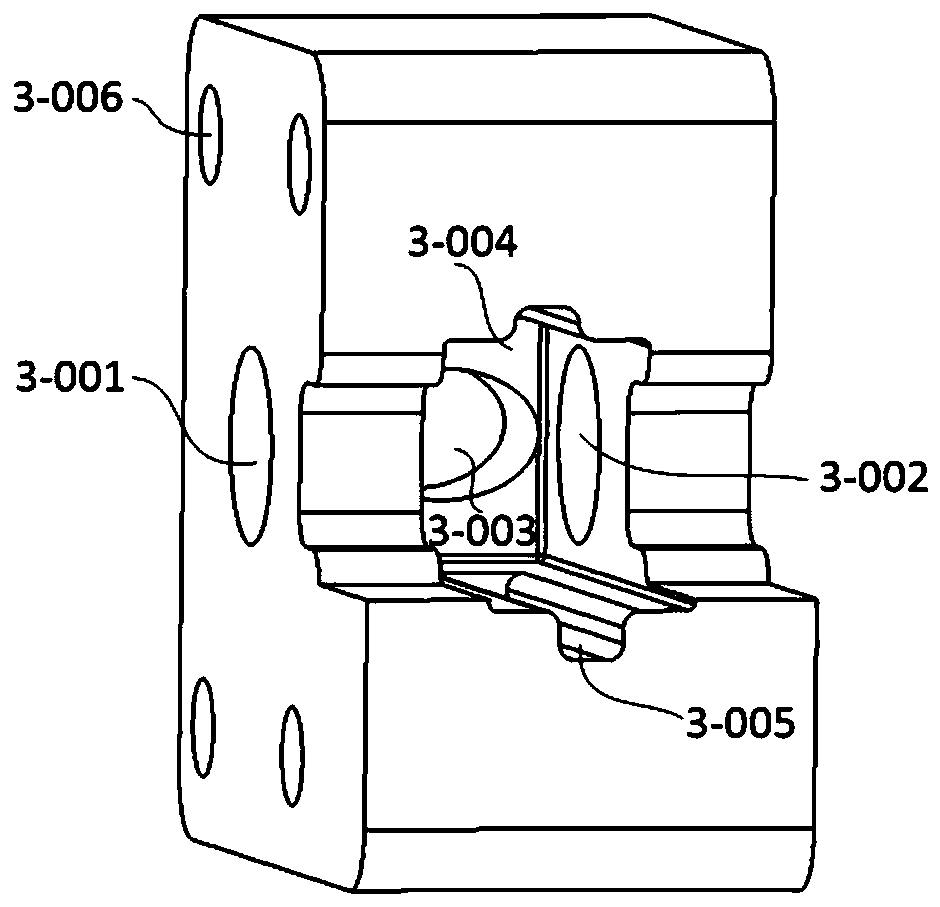

[0037] In a typical implementation of the present invention, please refer to Figure 4 , this embodiment discloses an extrusion die for realizing a two-way extrusion forming process, including a punch 8 and a die 7, and the punch 8 and the die 7 are matched;

[0038] The die 7 has an opening as a discharge port, the opening is provided with a working belt, and the shape of the opening is consistent with the cross-sectional shape of the outer surface of the hollow profile product.

[0039] The punch 8 has two inlets and one outlet, and the two inlets are respectively located on the first side and the second side of the punch 8, and the first side and the second side of the punch 8 are the sides of the punch 8. On two opposite sides, the outlet is located on the third side, the third side is located between the first side and the second side, the axes of the two inlets are on the same straight line, and are perpendicular to the axis of the outlet.

[0040] It can be understood ...

Embodiment 2

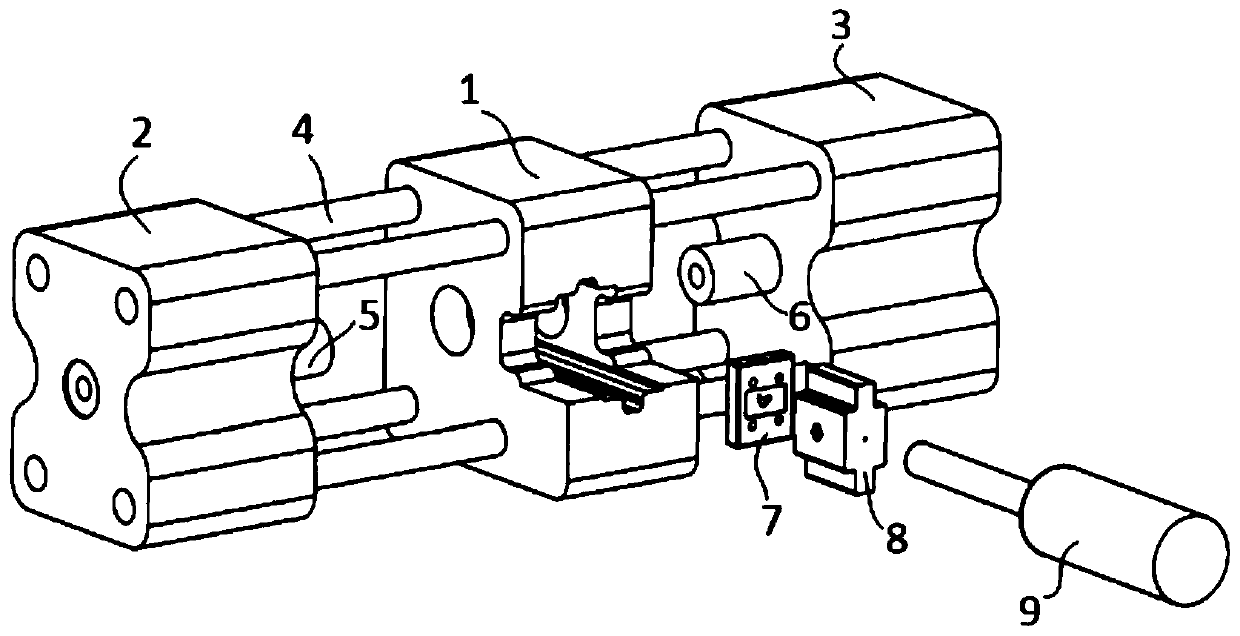

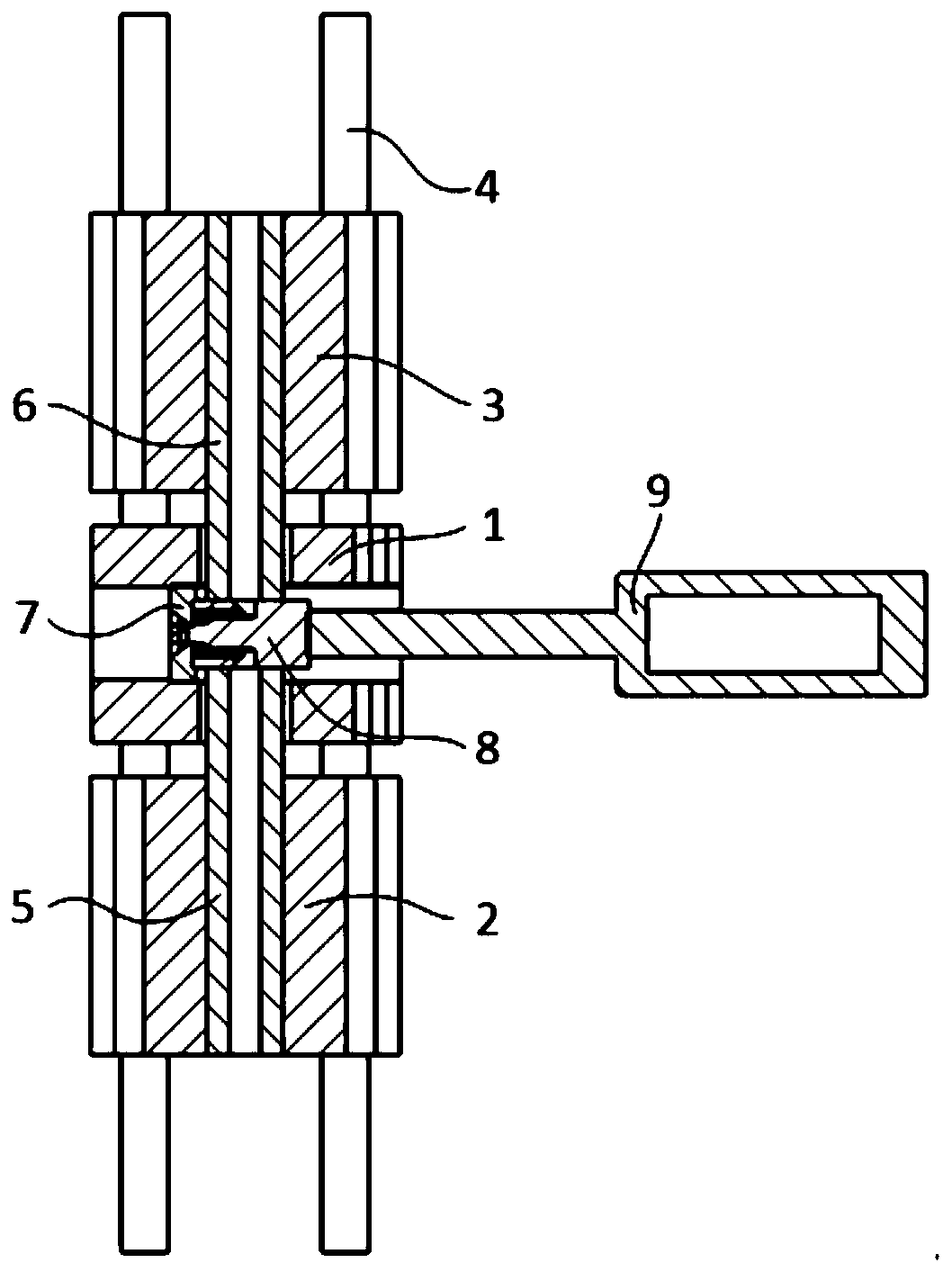

[0045] In a typical embodiment of the present invention, such as figure 1 As shown, this embodiment discloses an extrusion device for realizing a two-way extrusion forming process, including a center beam 1 of an extrusion machine, an extrusion cylinder beam 2, an extrusion cylinder beam 3, a connecting rod 4, a first extrusion cylinder 5. The second extrusion barrel 6 and the hydraulic push-pull rod 9 also include the bidirectional extrusion die disclosed in Embodiment 1. in such as figure 1 In the structure shown, the central beam 1 of the extruder is located at the center, and there is an extrusion cylinder beam and an extrusion cylinder on its left and right sides, and the central beam 1 of the extruder and the extrusion cylinders on its left and right sides The crossbeam is connected by connecting rod 4.

[0046] That is, the two sides of the central beam 1 of the extruder are respectively connected to the beam 2 of the first extrusion cylinder 5 and the beam 3 of the s...

Embodiment 3

[0059] In a typical implementation of the present invention, embodiment 3 provides an extrusion method for realizing a bidirectional extrusion forming process, using the extrusion device disclosed in embodiment 2 for realizing a bidirectional extrusion forming process, Include the following steps:

[0060] Before the two-way extrusion, the die 7 and the punch 8 are connected together through the connecting and positioning parts on them, and they are moved from the die entrance of the center beam 1 of the extrusion machine along the chute 3-005 through the hydraulic push-pull rod 9 Push. The hydraulic push-pull rod 9 exerts a certain pressure on the extrusion die so that the die 7 and the punch 8 are locked to each other;

[0061] Put the two extrusion bars into the first extrusion cylinder 5 and the second extrusion cylinder 6 respectively through the feeding mechanism, and then make the first extrusion cylinder 5 beam 2 and the second extrusion cylinder 5 through a certain h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap