Side face splicing welding device for new energy electric vehicle basket machining

A welding device and electric vehicle technology, applied in auxiliary devices, welding equipment, metal processing, etc., can solve problems such as difficult to fix the base and side ring of the car basket, easy to produce relative movement, and affect welding quality, etc., to achieve good fixing effect and easy operation Convenience and the effect of ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

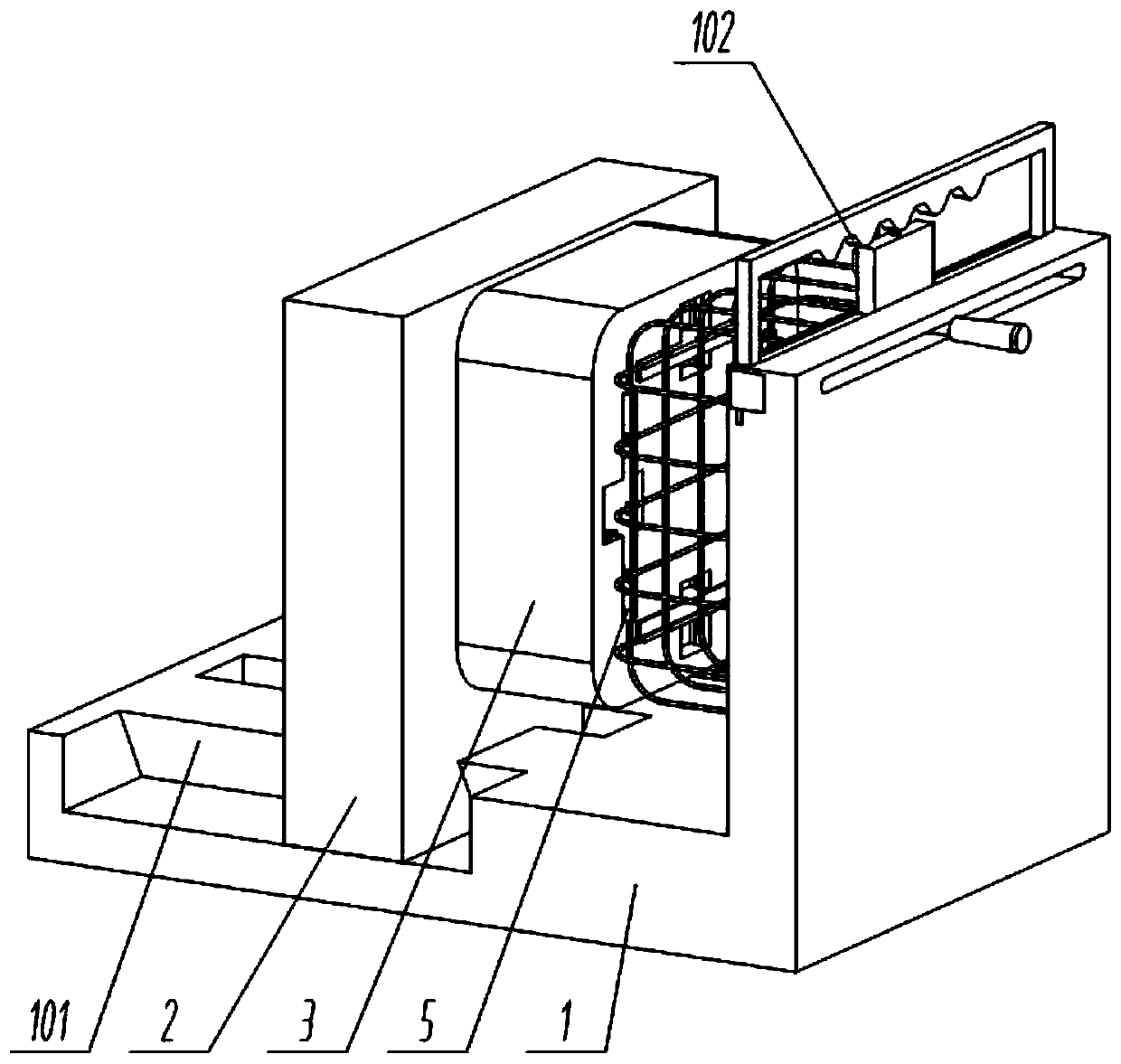

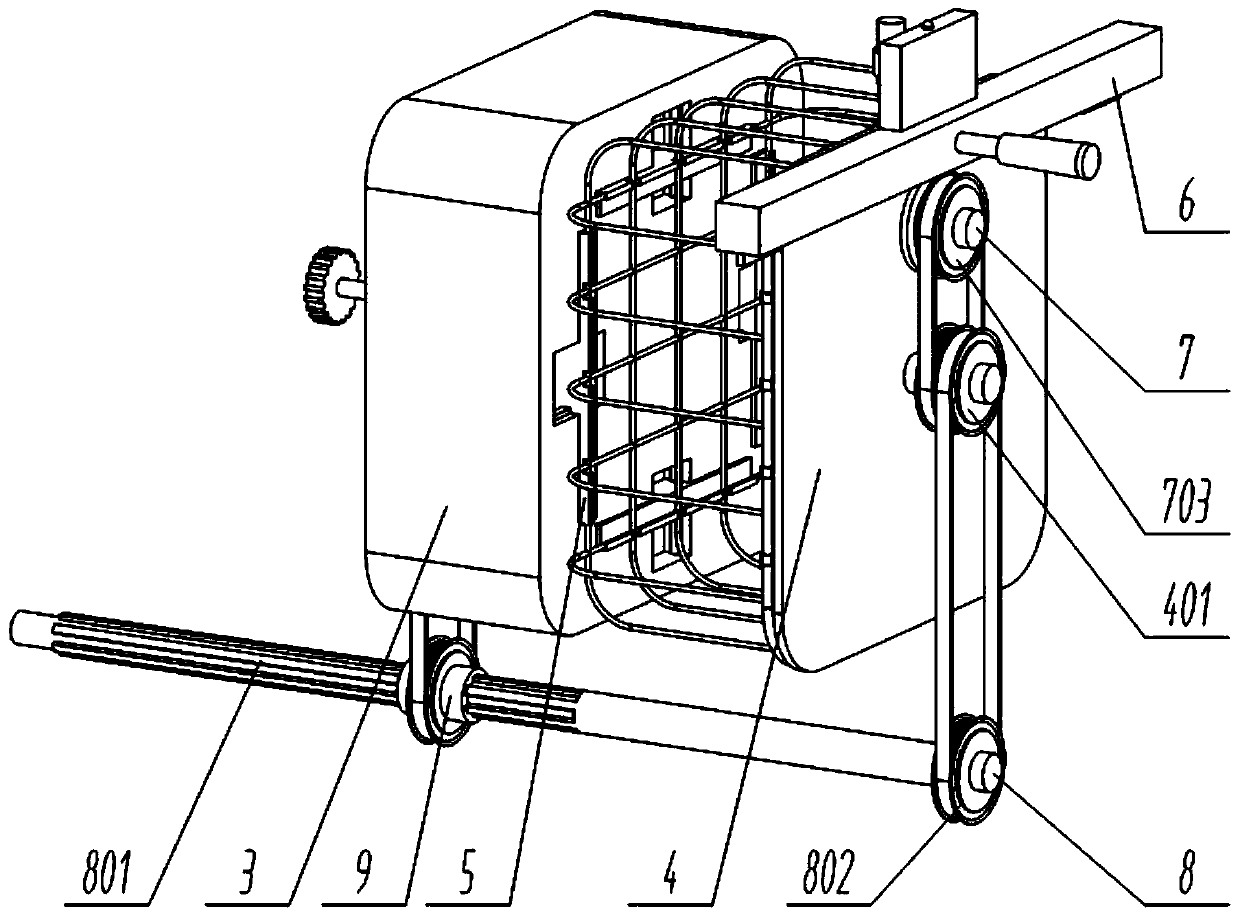

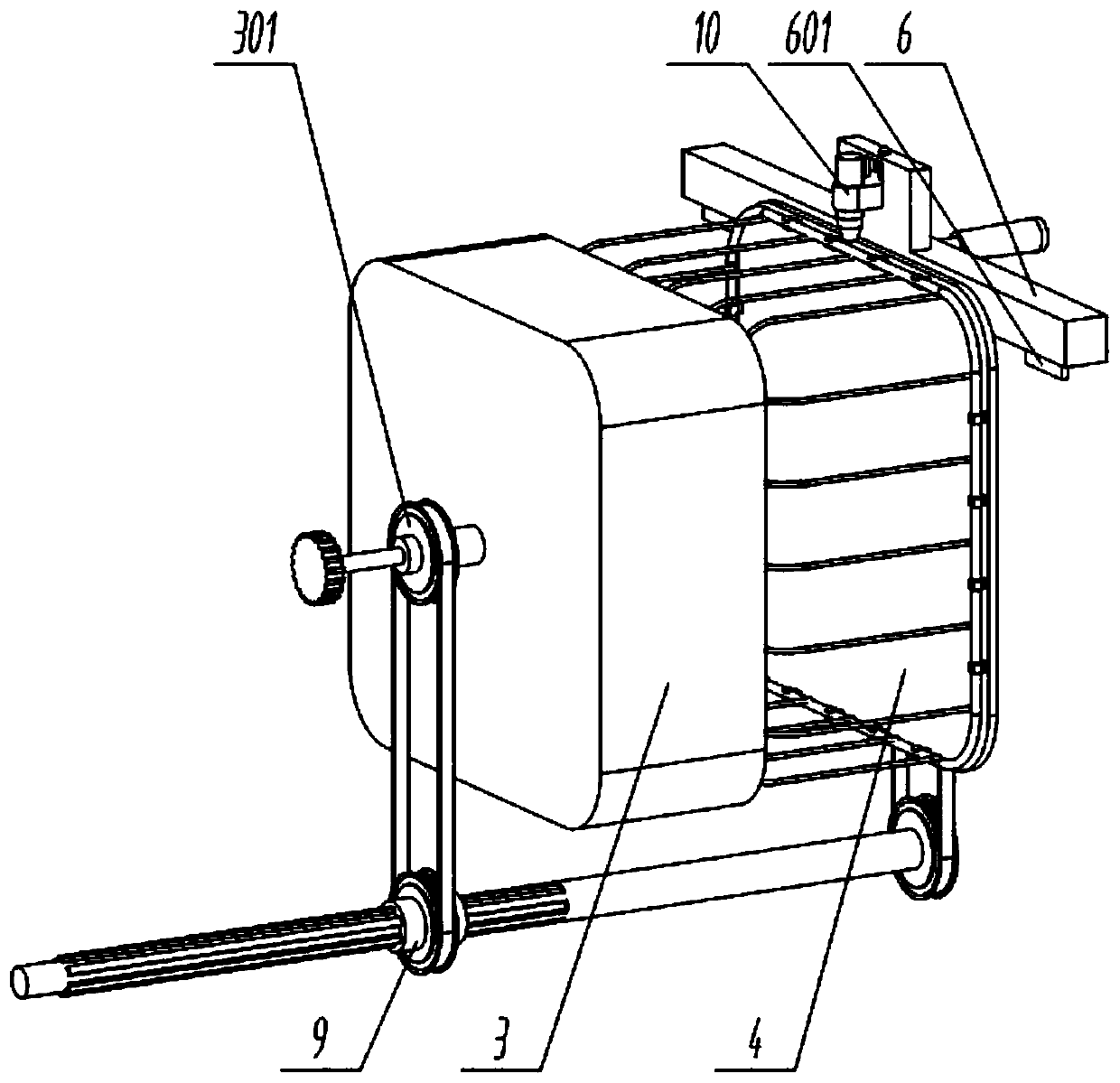

[0029] see Figure 1 to Figure 8, an embodiment provided by the present invention: a side splicing and welding device for processing the basket of a new energy electric vehicle, including a base 1; a group of sliding blocks 2 are slidably connected to the upper left side of the base 1; the base 1 also includes a sliding wire block 101, a group of sliding wire blocks 101 are arranged on the left top of the base 1, and the sliding block 2 is slidably connected to the base 1 through the sliding wire blocks 101, and the sliding block 2 is guided by the sliding wire blocks 101 in use; the right end surface of the sliding block 2 A group of basket bottom installation platf...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap