Assembling device for machining fuel tank switch

A technology for assembling devices and automobile fuel tanks, which is applied to metal processing equipment, assembling machines, manufacturing tools, etc., can solve the problems of angle and position deviation, waste, and inability to automate workpiece processing, and achieves ease of use, avoidance of angle deviation, and convenience. The effect of calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

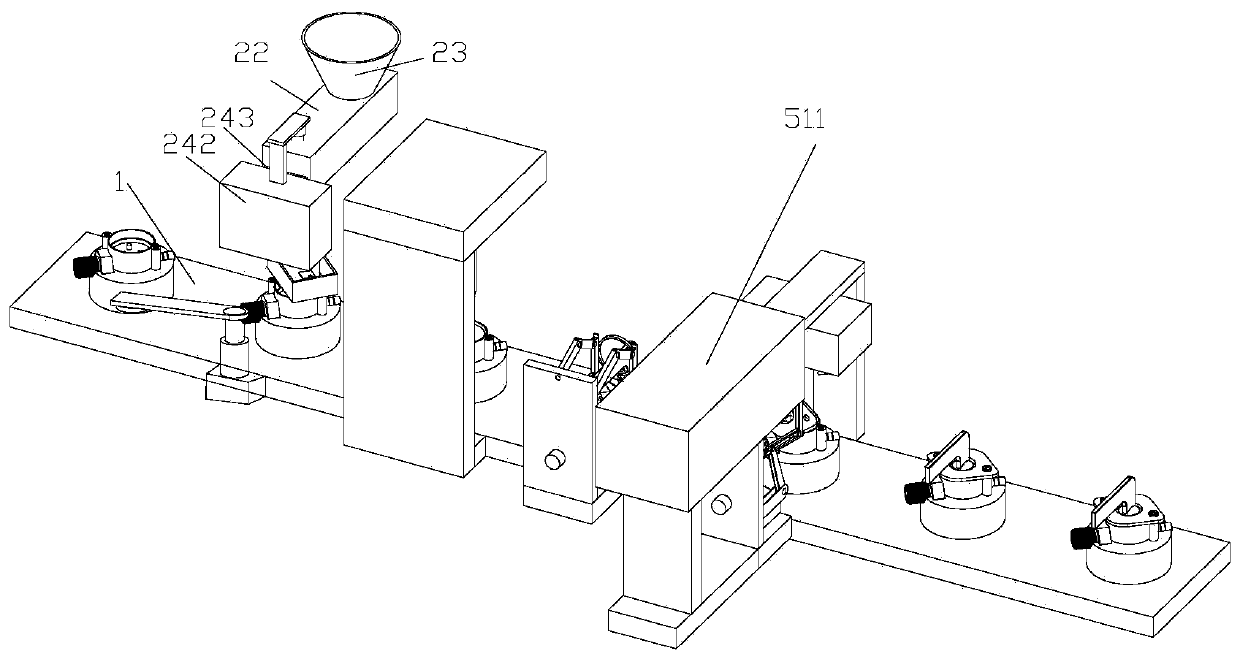

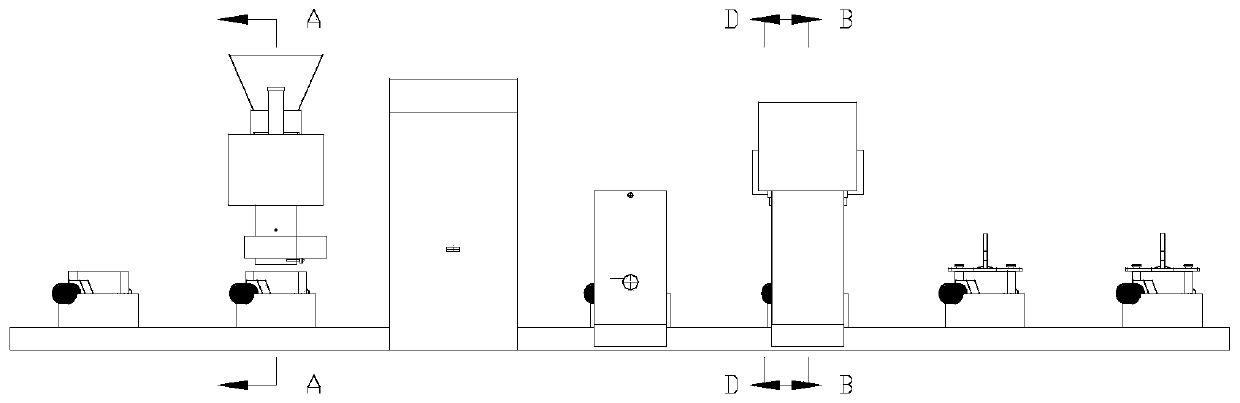

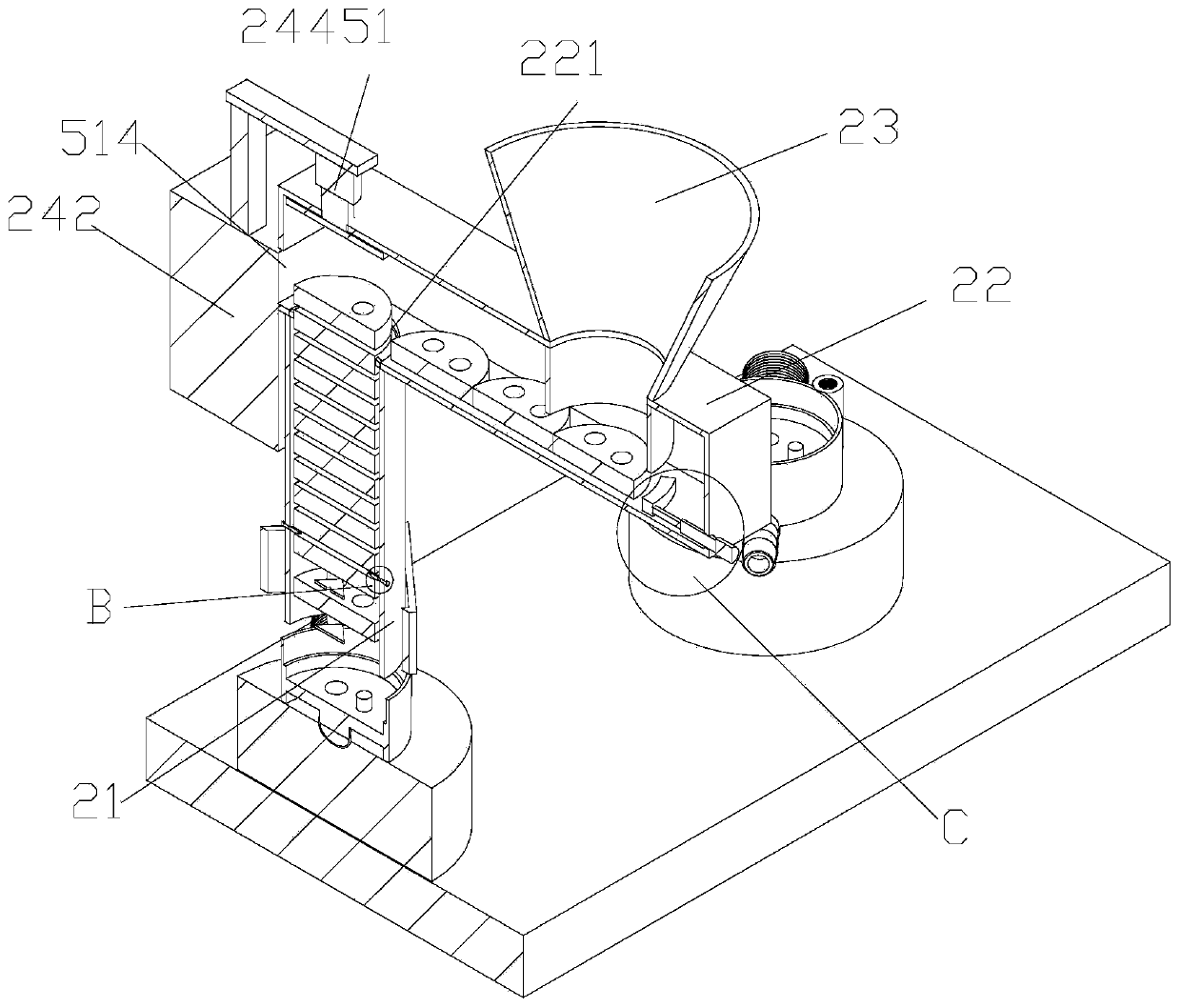

[0024] Such as Figure 1-12As shown, an assembly device for automotive fuel tank switch processing includes a conveyor belt 1, a seal ring placement device, a handle placement device, a gasket placement device and a fixing device, and the seal ring placement device includes a The feeding tube 21 in the feeding tube, the supply chamber 22 for putting the sealing ring into the feeding tube 21, the storage bucket 23 arranged on the supply room 22, the screening part and the blanking part provided on the feeding tube 21; Screening part comprises the first push plate 241 that is located in the replenishment chamber 22, the recovery box 242 that is located at one side of the supply chamber 22, the first through hole 243 that is located between the recovery box 242 and the supply chamber 22, is located in the feeding tube 21 on the guide fixture; the guide fixture includes an outer tube 2441, two limiting plates 2442 located on the upper middle part of the inner wall of the outer tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com