Circular tubular catheter tip forming machine

A catheter tip and molding machine technology, applied in the field of medical devices, can solve problems such as affecting catheter molding, poor environmental adaptability, and temperature rise of induction coils, and achieve the effects of precise control of molding temperature, good molding, and accurate cutting action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

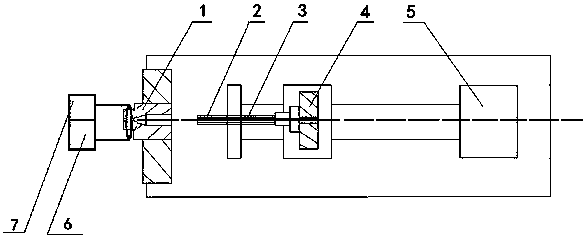

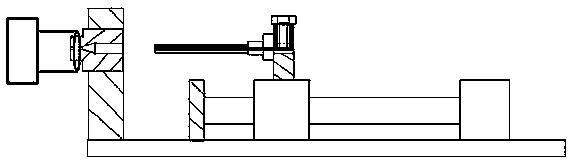

[0019] see figure 1 and figure 2 , Embodiment 1 of the present invention includes:

[0020] A round tubular catheter tip forming machine, comprising a tip forming mold 1, a catheter 2, a core needle 3, a core needle clamp 4, a heating controller 6 and a motor-driven stroke control device, the core needle 3 is fixed on the core needle clamp On the device 4, the core needle clamp 4 is fixed on the motor-driven stroke control device, the catheter 2 is sleeved outside the core needle 3, the heating controller 6 is connected with the tip forming mold 1, and the motor-driven stroke control device will The catheter 2 and the core needle 3 are sent into the tip forming mold 1 to complete the molding, and the stroke of the motor-driven stroke control device is cut off by the catheter 2, and the core needle 3 and the tip forming mold 1 are controlled on and off.

[0021] Install the core needle 3 on the core needle clamp 4, then install the catheter 2 on the core needle 3, set the mo...

Embodiment 2

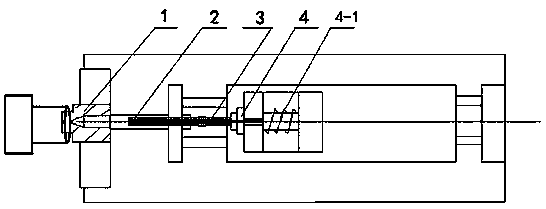

[0026] see image 3 and Figure 4 , Embodiment 2 of the present invention includes:

[0027] A round tubular catheter tip forming machine, comprising a tip forming mold 1, a catheter 2, a core needle 3, a core needle clamp 4, a heating controller 6 and a cylinder-driven stroke control device, the core needle 3 is fixed on the core needle clamp On the device 4, the core needle clamp 4 is fixed on the cylinder-driven stroke control device, the catheter 2 is sleeved outside the core needle 3, the heating controller 6 is connected with the tip forming mold 1, and the cylinder-driven stroke control device will The conduit 2 and the core needle 3 are sent into the tip forming mold 1 to complete the molding, and the stroke of the cylinder-driven stroke control device is cut off by the conduit 2, and the core needle 3 and the tip forming mold 1 are controlled on and off.

[0028] The core needle clamp 4 is connected with a clamp buffer 4-1, and the spring pressure on the clamp buffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com