A damping rubber production line and rubber production process

A damping rubber and production line technology, applied in the field of damping rubber production, can solve the problems of excessive dust contamination of rubber raw materials, inconsistency in connection, and impact on the quality of rubber products, so as to reduce unnecessary transmission, ensure continuity, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

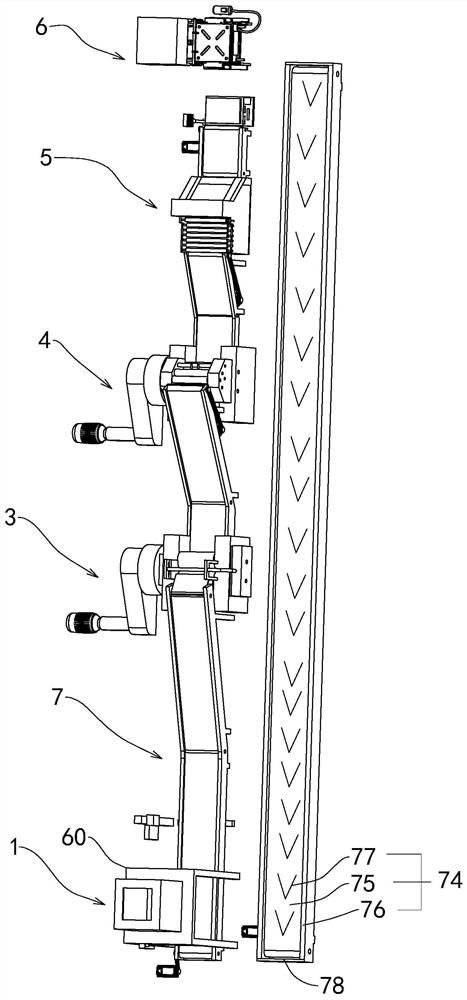

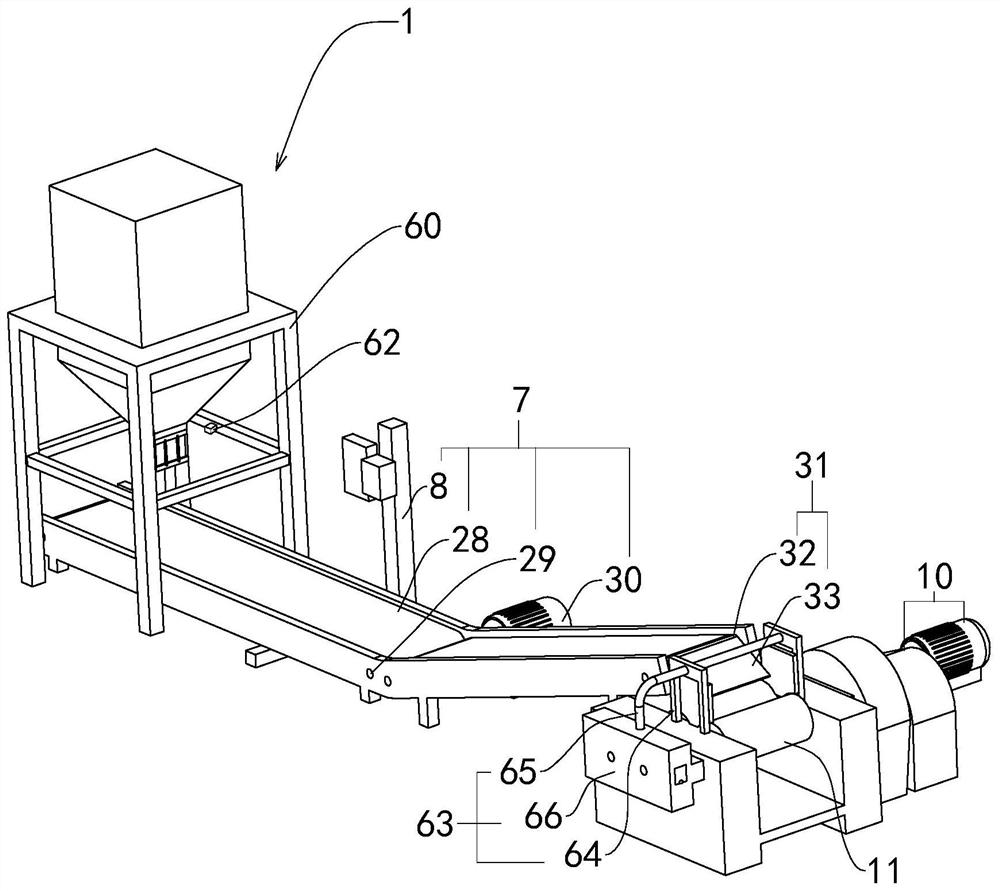

[0062] refer to figure 1 , is a damping rubber production line disclosed in the present invention, comprising a stirring device 1, the stirring device 1 is provided with a second bracket 60 for supporting the entire stirring device 1, and the bottom of the stirring device 1 is provided with a bottom for stirring and mixing the stirring device 1. The discharge pipe 2 through which the finished rubber material is discharged, and the bottom of the discharge pipe 2 is provided with a primary conveying assembly 7 for conveying rubber. One side along the extension direction of the primary conveying assembly 7 is provided with a preliminary banburying mechanism 3 , a deep kneading mechanism 4 , a cutting mechanism 5 and a thermoforming mechanism 6 .

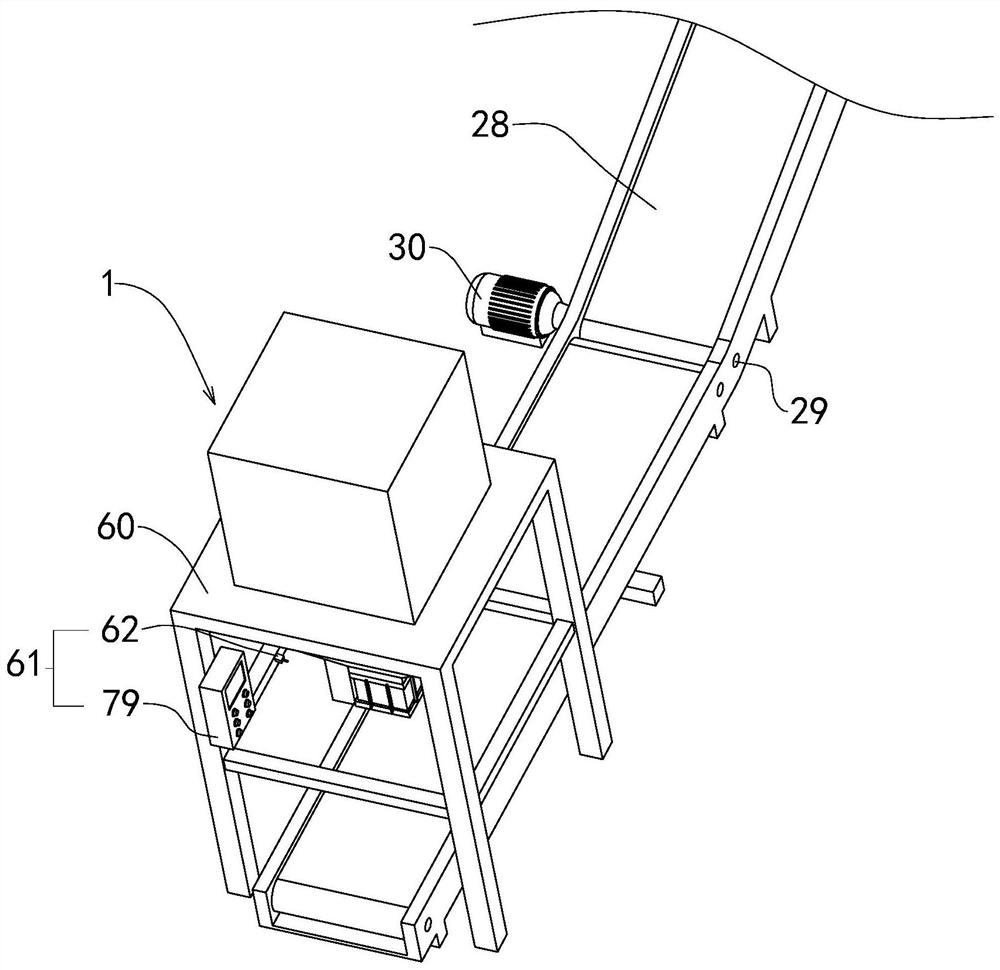

[0063] refer to figure 2 and image 3 , the stirring device 1 is provided with a control assembly 61 fixed on the second support 60, the control assembly 61 includes a controller 79 and a control sensor 62 fixed on the second support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com