Environment-friendly glue-free self-adhesive floor

A glue-free, environment-friendly technology, applied to elastic floors, floors, coverings/linings, etc., can solve the problems that the bonding efficiency cannot be compared with glue, it is not conducive to people's daily life, and the floor replacement is inconvenient, etc., to achieve enhanced connection stability High performance, simple structure, and the effect of reducing the pasting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

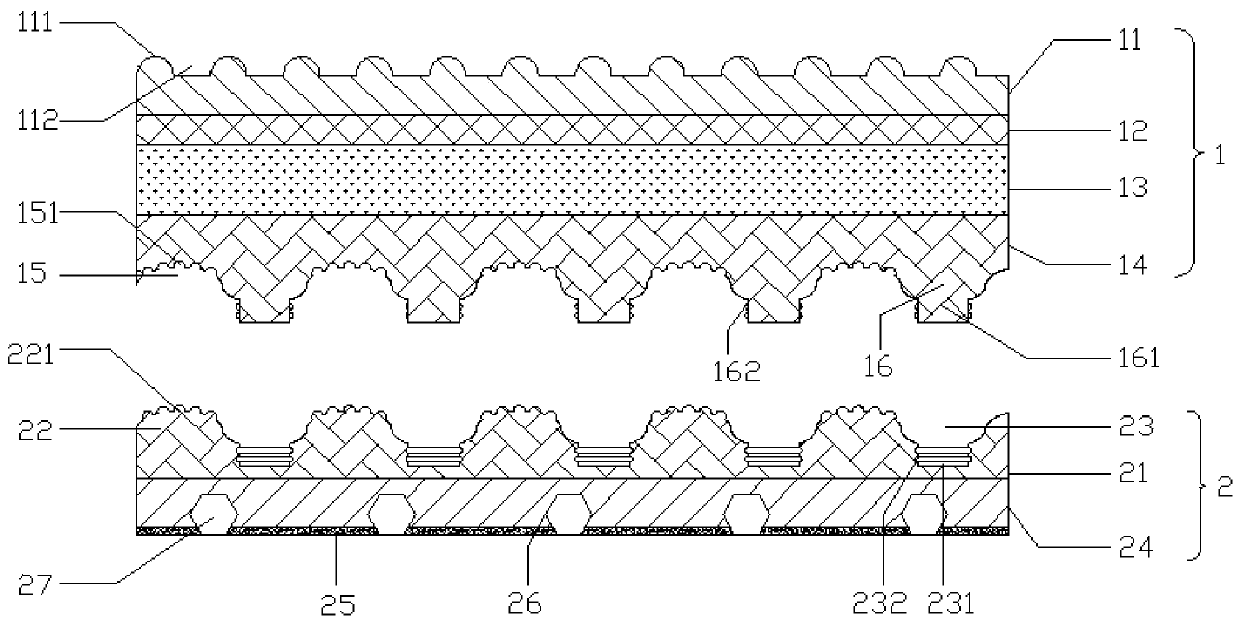

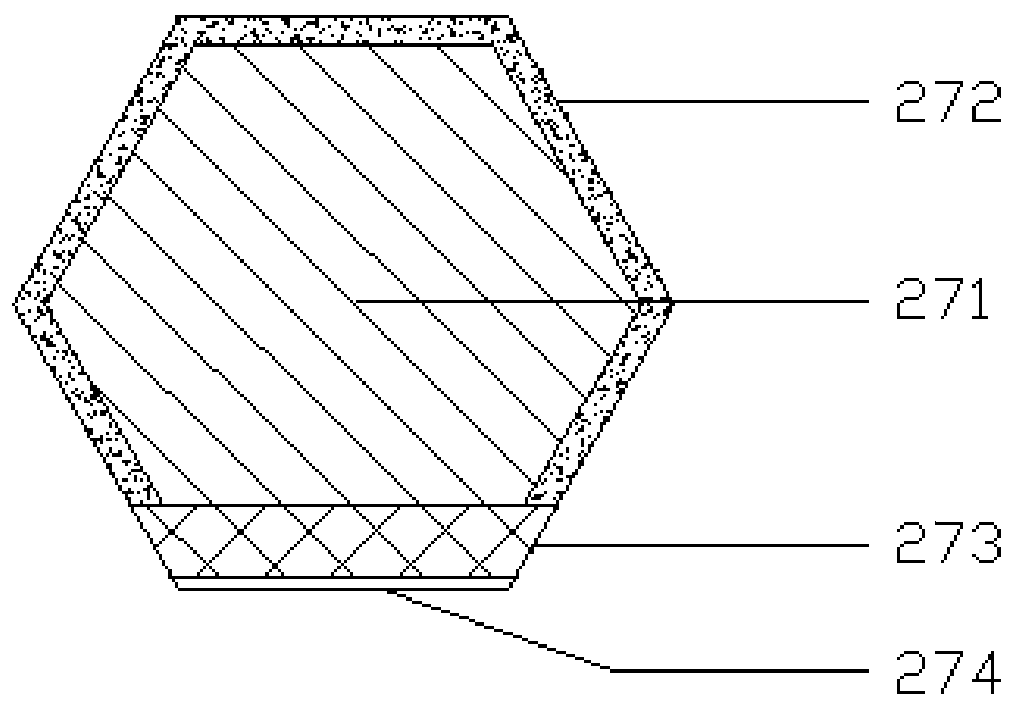

[0019] Referring to the accompanying drawings, an environmentally friendly glue-free self-adhesive floor of the present invention comprises a self-adhesive floor upper half 1 and a self-adhesive floor lower half 2, and the self-adhesive floor upper half 1 also includes a non-slip and wear-resistant layer 11, Design and color decoration layer 12, substrate layer 13, upper splicing layer 14, upper splicing groove 15 and upper splicing protrusion 16, the bottom of described anti-slip and wear-resistant layer 11 is provided with design and color decoration layer 12, and the bottom of described design and color decoration layer 12 A base material layer 13 is provided, and an upper splicing layer 14 is provided at the bottom of the base material layer 13, and several upper splicing grooves 15 and upper splicing protrusions 16 are provided at the bottom of the upper splicing layer 14, and the upper splicing concave The grooves 15 and the upper splicing protrusions 16 are distributed a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap