Recyclable large concrete cooling device

A cooling device and concrete technology, applied in the field of concrete, can solve problems such as concrete temperature cracks, affecting structural safety and normal use, and achieve the effects of saving energy and improving conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

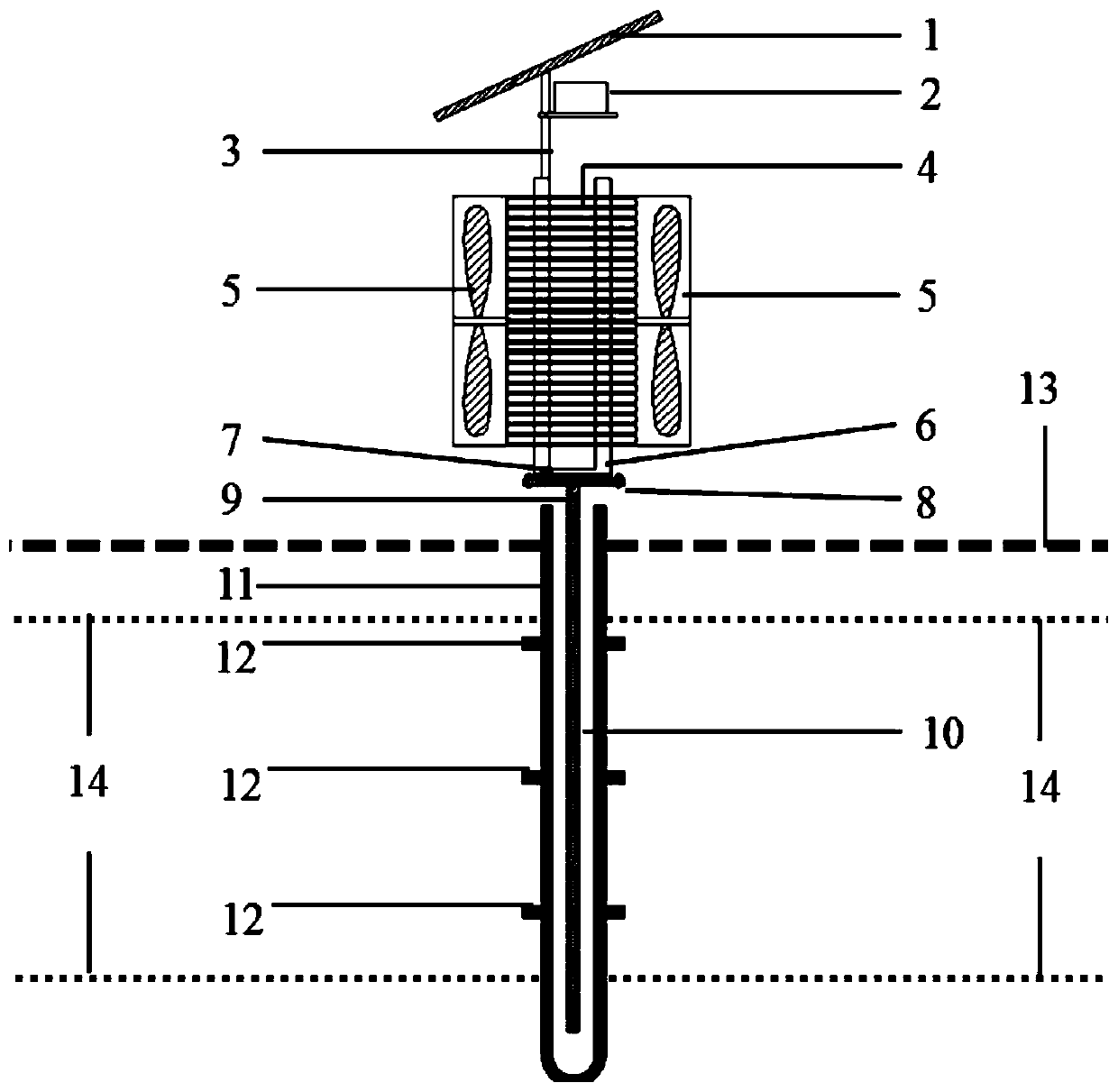

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0023] Such as figure 1 As shown, this embodiment includes a self-generating module forming a heat conduction device, an air-cooled heat dissipation module and a heat transfer medium, and also includes a single-side sealing sleeve 11 on which three evenly distributed water stop rings 12 are provided.

[0024] The self-generating module includes a battery pack and a transformer 2, the battery pack and the transformer 2 are electrically connected to the solar photovoltaic panel 1, and are installed on the air-cooled heat dissipation module through a bracket 3 to provide electric energy for the air-cooled heat dissipation module to realize the present invention. The power of the device is self-sufficient, and does not require cumbersome tow wires t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com