Directional wire-line coring drilling tool and drilling method thereof

A wireline coring and drilling tool technology, which is applied in the field of drilling, can solve the problems of inner tube drilling tool stuck, inner tube drilling tool stalling and sliding, etc., and achieve the effect of increasing drilling times, high drilling efficiency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

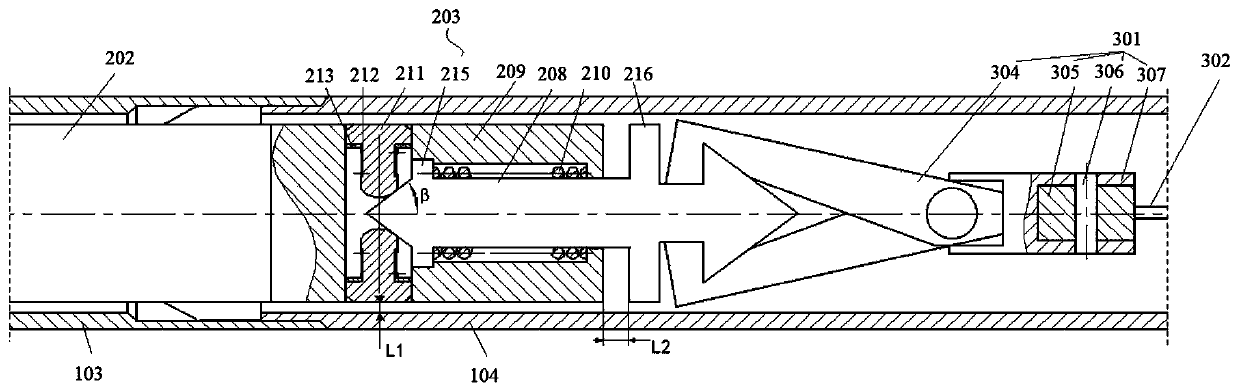

[0043] This embodiment discloses a stall braking device for a directional wireline core drilling tool, such as Figure 4 As shown, the device includes a spear head 208, a brake body 209, a brake spring 210, a block 211, a return spring 212 and a support member 213 for resetting the block 211;

[0044] Wherein, the center of the brake body 209 is provided with a first through hole 214 for setting the spear head 208 through the brake body 209 axially; The first limiting block 215 and the second limiting block 216 are respectively arranged at two ends of the braking body 209 . In this embodiment, the middle part of the spear head 208 is a rod body structure, and both ends are tapered structures, and the first limit block 215 is a disc-shaped flange, which is arranged between the rod body in the middle part of the spear head 208 and one of the tapered ends. ; The second limit block 216 is also a disc-shaped flange, which is arranged near the connection between the other tapered end...

Embodiment 2

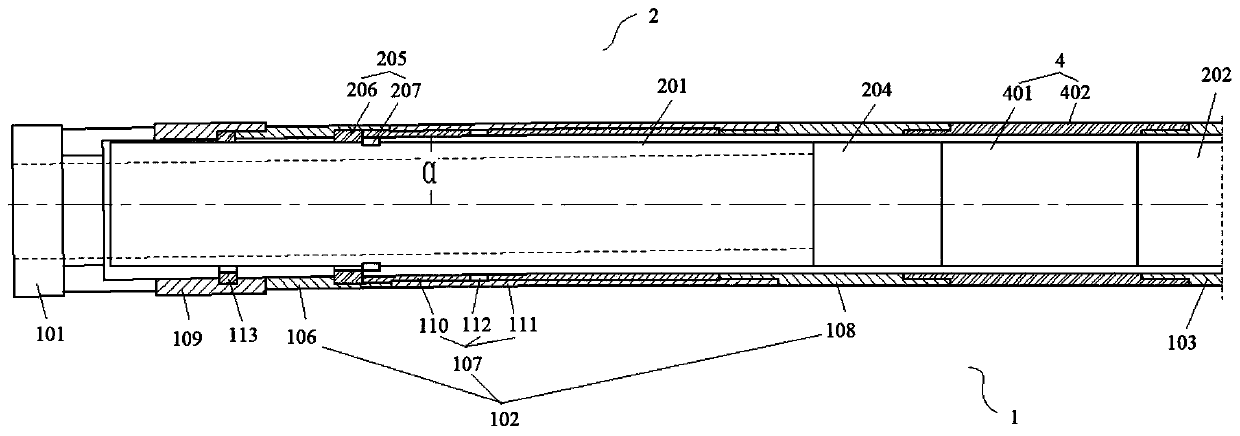

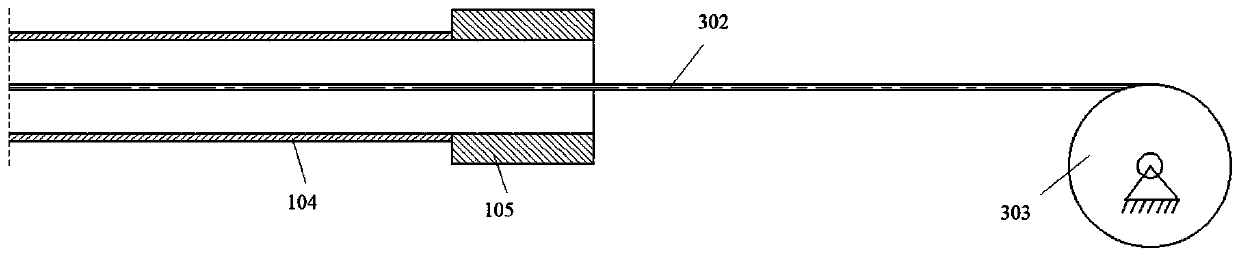

[0049] This embodiment discloses a directional wireline core drilling tool, such as Figure 1 to Figure 3 As shown, the core drilling tool includes an outer pipe unit 1 , an inner pipe unit 2 used in conjunction with the outer pipe unit 1 , and a fishing unit 3 for fishing the inner pipe unit 2 . Wherein, the outer tube unit 1 includes a coring bit 101, an outer tube body 102, a cartridge chamber 103, a coring drill rod 104 and a water stool 105 arranged coaxially in sequence; the inner tube unit 2 includes a rock core arranged coaxially in sequence The pipe 201, the ejection card 202 and the stall braking device 203 that are clamped in the ejection chamber 103, the stall braking device 203 is the stall braking device described in Embodiment 1, wherein the salvage unit 3 and the stall braking device 203 Spearhead 208 connection. The ejection card 202 and the ejection card chamber 103 are conventional structures of drilling tools currently on the market.

[0050] In this embo...

Embodiment 3

[0055] The difference between this embodiment and Embodiment 2 is that the directional wireline coring drilling tool of this embodiment also includes an inclinometer unit 4, and the inclinometer unit 4 includes an inclinometer 401 and a non-magnetic drill pipe pup joint 402, and the non-magnetic drill pipe The puppet 402 is set between the outer tube body 102 and the cartridge chamber 103, the inclinometer 401 is set within the range of the non-magnetic drill pipe puppet 402, and if the impactor 204 is added, it is set between the impactor 204 and the cartridge 103 between. The inclinometer 401 of this embodiment is a storage type inclinometer.

[0056] The inclinometer 401 measures the inclination at equal time intervals, and stores the test data inside the instrument, reads the data or replaces the battery every time the inner tube unit 2 is salvaged, draws the time curve of the hole inclination, and adjusts the coring bit according to the hole inclination data 101 azimuth,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com