Wind power generator set

A technology for wind turbines and nacelles, which is applied in wind turbines, wind power generation, engines, etc., can solve the problems of many space layout restrictions, and the overall heat dissipation effect of heat exchangers is small, so as to improve heat dissipation capacity, improve structural compactness and Arrangement feasibility, effect of meeting cooling requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

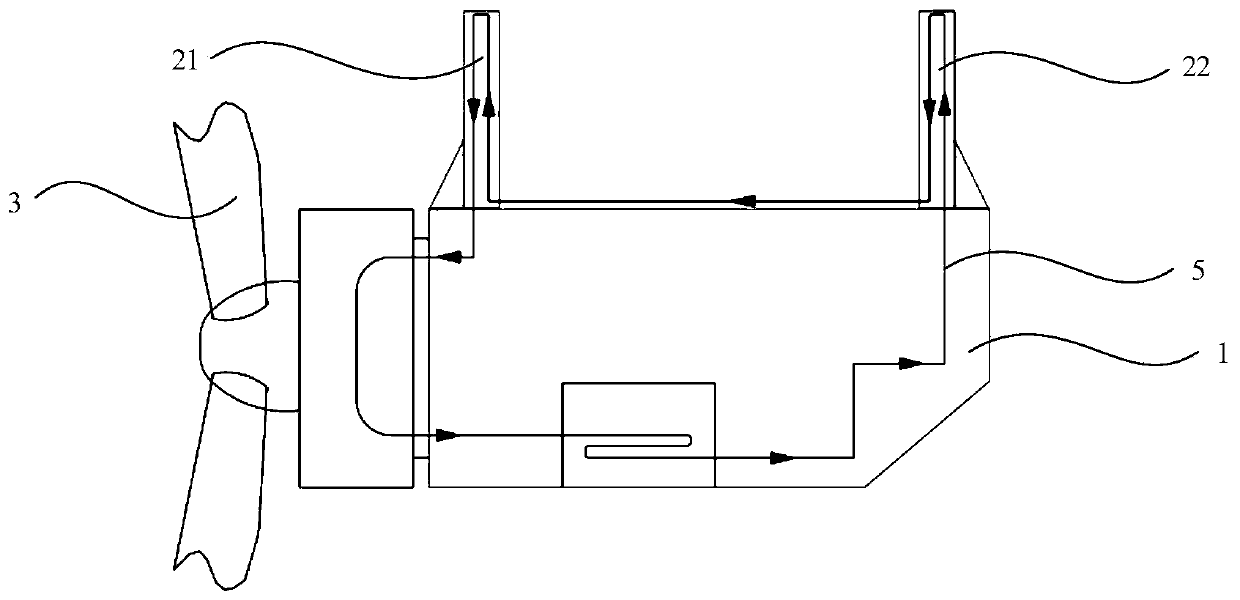

Embodiment 1

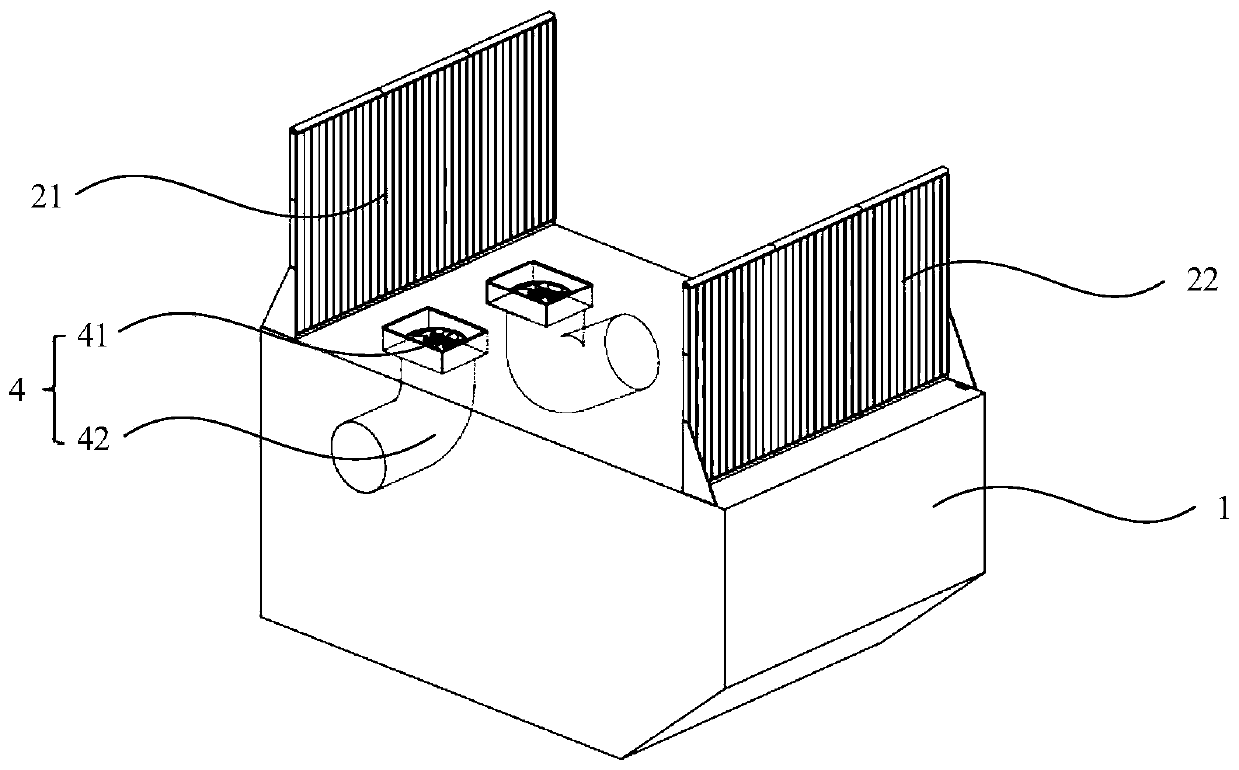

[0046] This embodiment provides a wind power generating set, such as figure 1 As shown, the wind power generating set includes a nacelle 1 and two heat exchangers arranged outside the nacelle 1 and connected to the nacelle 1 . Two heat exchangers are arranged on the first outer surface of the nacelle 1 and arranged at intervals along the axial direction of the wind power generating set. Along the flow direction of the outside air, the heat exchanger located upstream is the upstream heat exchanger 21, and the heat exchanger located downstream is The heat exchanger is the downstream heat exchanger 22 . Wherein, the flow direction of the outside air is from the blades 3 of the wind power generator to the nacelle 1 along the axial direction of the wind power generator.

[0047] It should be noted that the first outer surface of the nacelle 1 refers to the upper end surface of the nacelle 1 in this embodiment, and in other alternative embodiments, the first outer surface can also ...

Embodiment 2

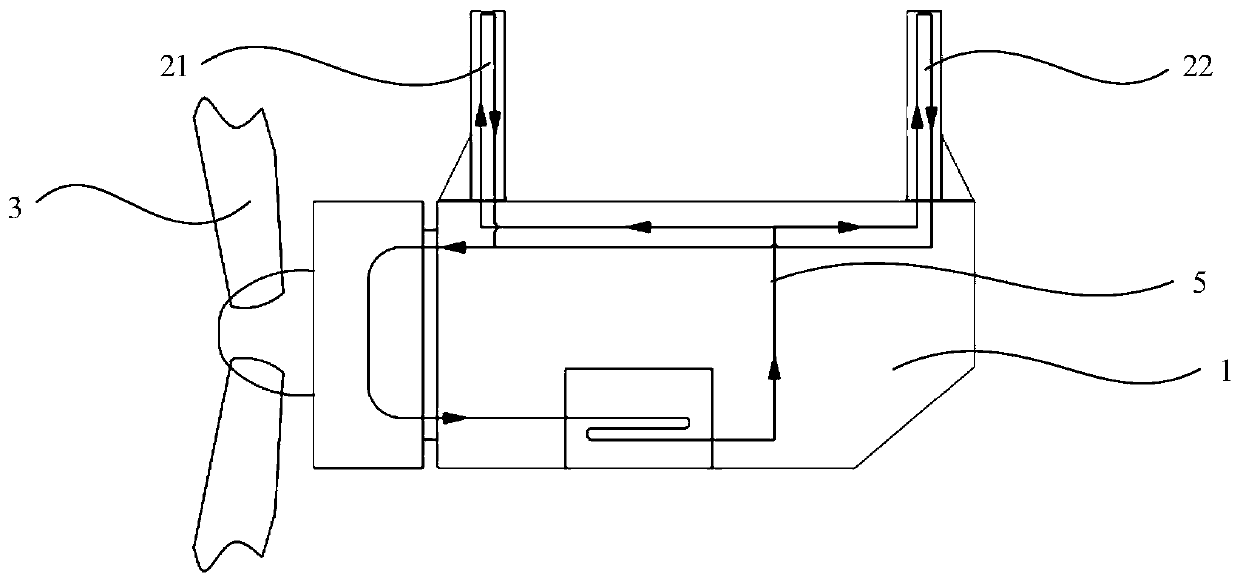

[0069] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the location of the suction device 4 is different.

[0070] like Figure 4 As shown, the suction device 4 is arranged between the upstream heat exchanger 21 and the downstream heat exchanger 22, and is arranged close to the leeward end of the upstream heat exchanger 21, so that it can absorb more hot air discharged by the upstream heat exchanger 21 in time. . Air suction device 4 is arranged on the side of heat exchanger, and hot air flows out by the side of heat exchanger, and air suction device 4 is arranged on the side of nacelle 1 so that air suction device 4 can not block the air flow on wind path. In order to ensure the timeliness and uniformity of the suction device 4 absorbing the hot air, heat exchangers should be arranged on both sides of the heat exchanger, so that the hot air can flow out from both sides of the heat exchanger.

[0071] Suction device 4 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com