Condenser refrigerating system based on liquid nitrogen

A refrigeration system and condenser technology, which is used in household refrigeration devices, coolers, lighting and heating equipment, etc., can solve the problems of difficult to control refrigeration power, high power consumption, and large temperature range restrictions by working fluids. Reduced manufacturing cost and operating cost, stable cooling effect, increased stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

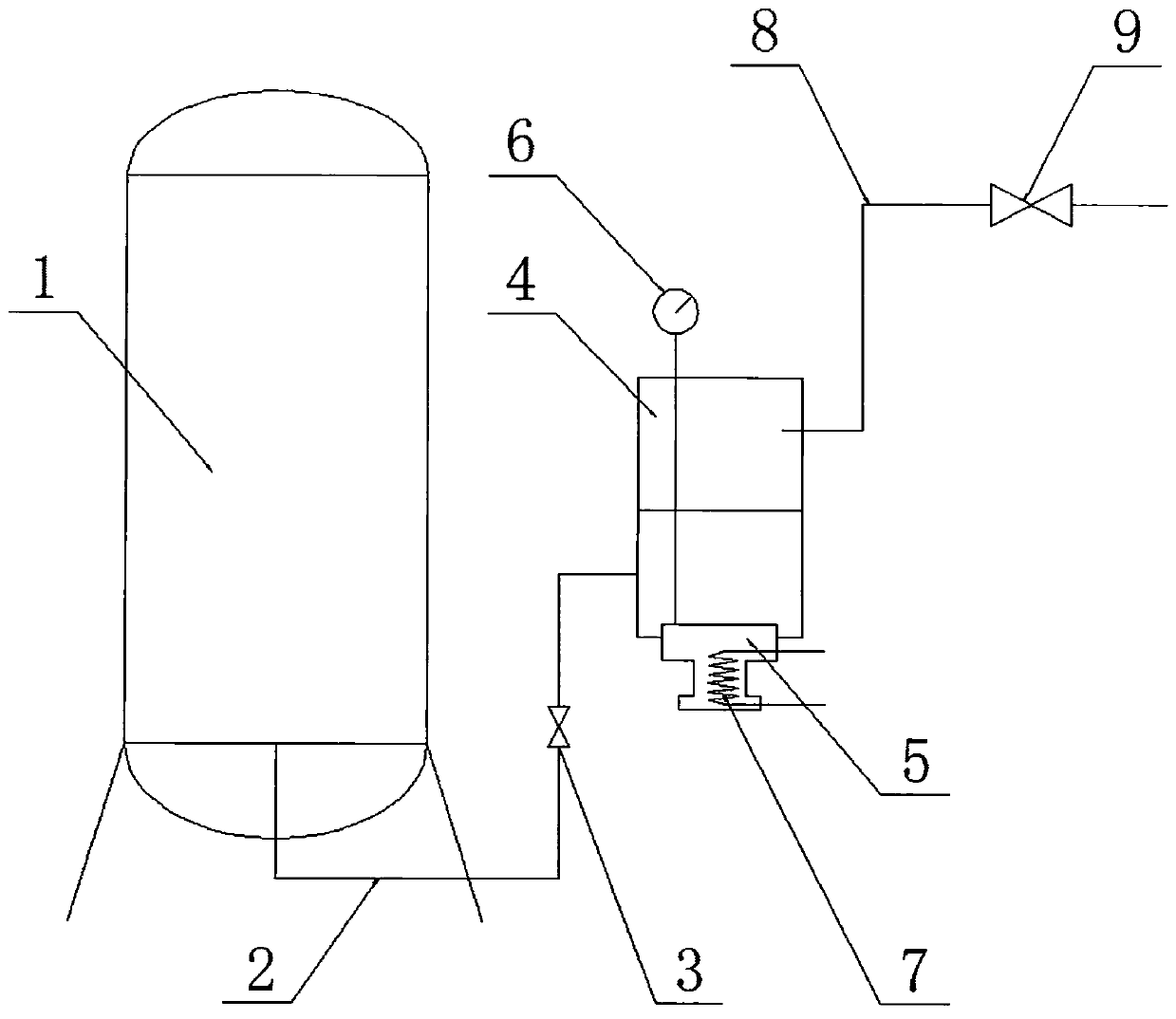

[0044] The cooling temperature of the condenser is required to be 150K, and the cooling power is 1000W. The specific design steps of the condenser refrigeration system based on liquid nitrogen are as follows:

[0045] The liquid nitrogen is pressurized to 0.5MPa in the liquid nitrogen Dewar 1, and enters the submerged liquid nitrogen storage 4 through the liquid nitrogen transmission pipeline 2. The total height of the submerged liquid nitrogen storage is greater than 200mm; the liquid level of the liquid nitrogen is adjusted by the liquid nitrogen flow control valve 3 and stabilized above 100mm.

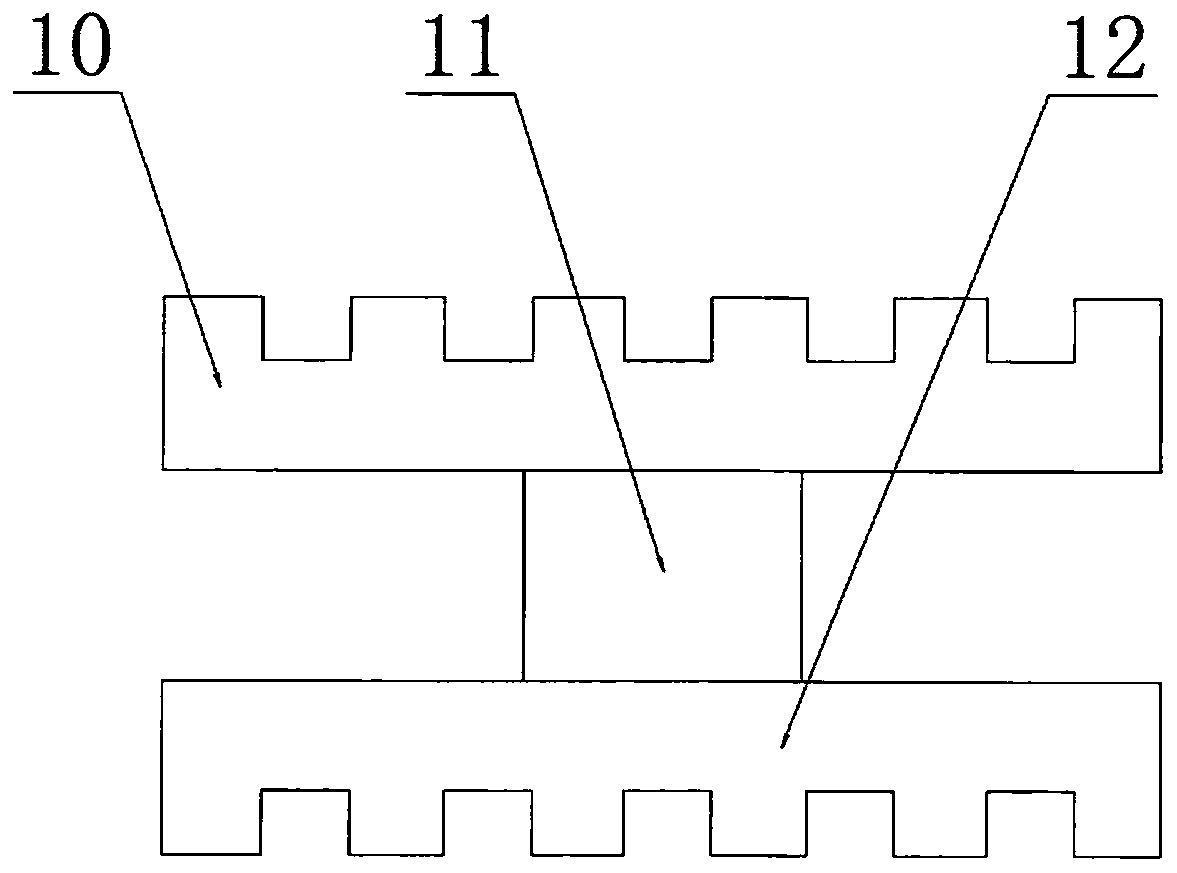

[0046] The size and height of the liquid nitrogen cold head 5 depend on the required cooling temperature zone and cooling power. Its detailed structure is as figure 2 As shown, it includes an evaporation expansion zone 10 , a heat conduction zone 11 and a condensation expansion zone 12 arranged in sequence from top to bottom.

[0047] For the demand of 150K and 1000W, the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com