Device used for monitoring microwave vacuum drying

A technology of microwave vacuum drying and microwave cavity, which is applied in heating devices, measuring devices, drying solid materials, etc., can solve the problems of affecting the accuracy of experiments, affecting the continuity of experiments, and little research on material color and shape changes. Effect of Physical Quality and Chemical Composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

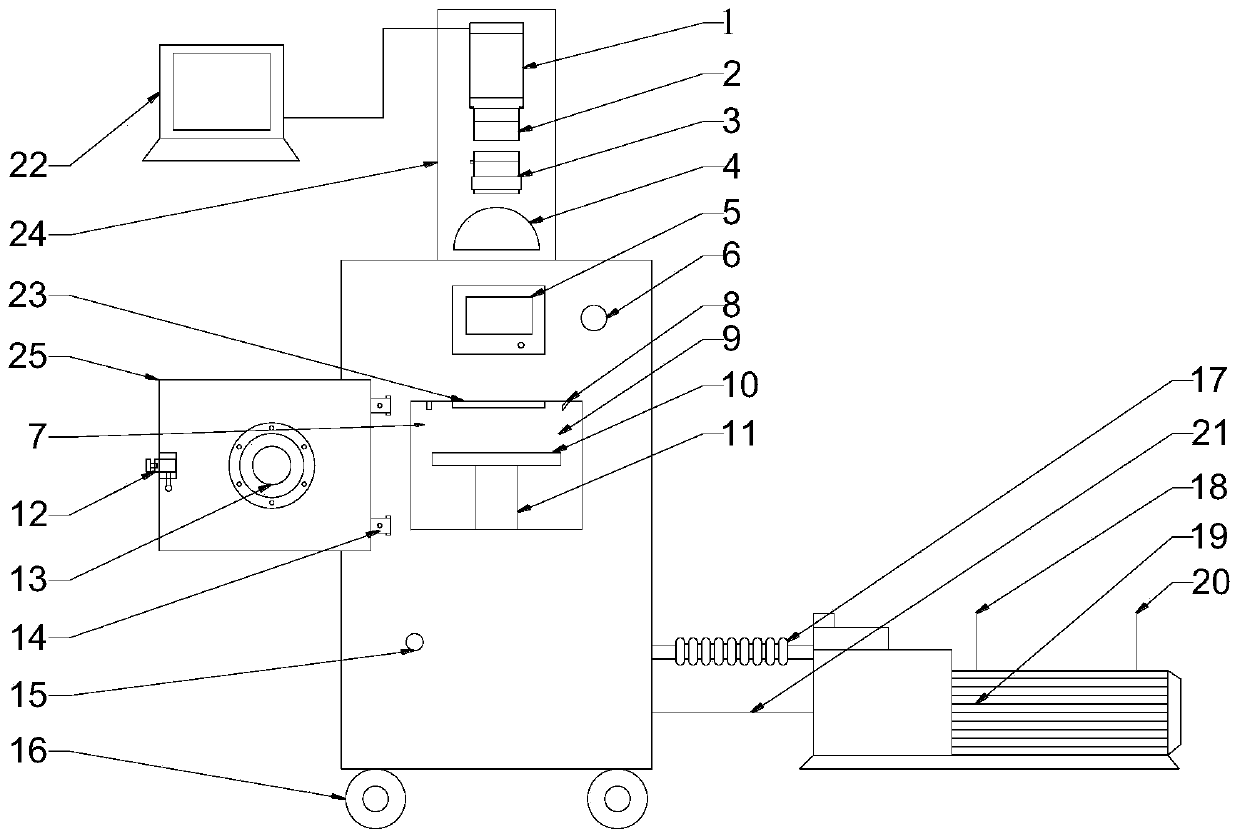

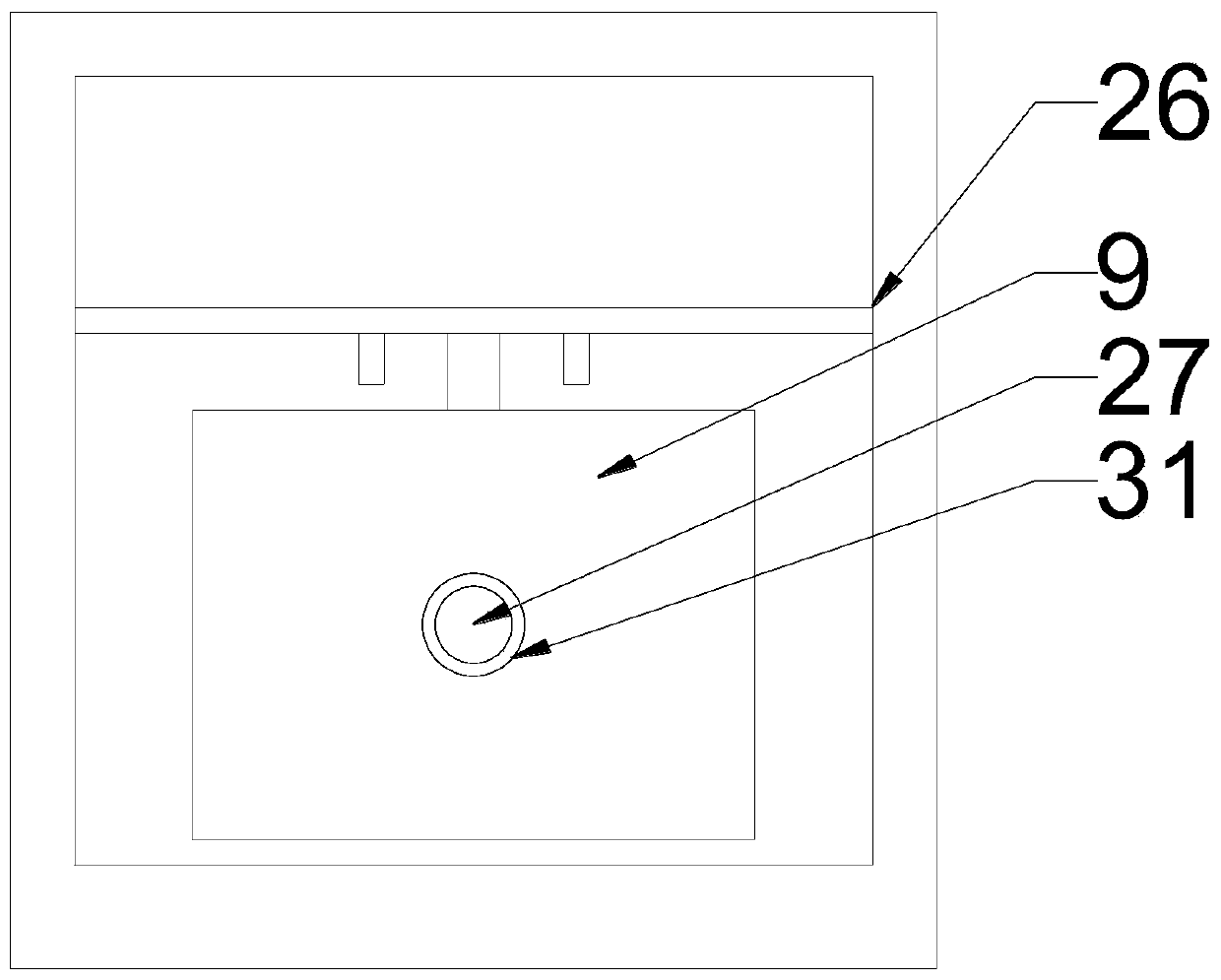

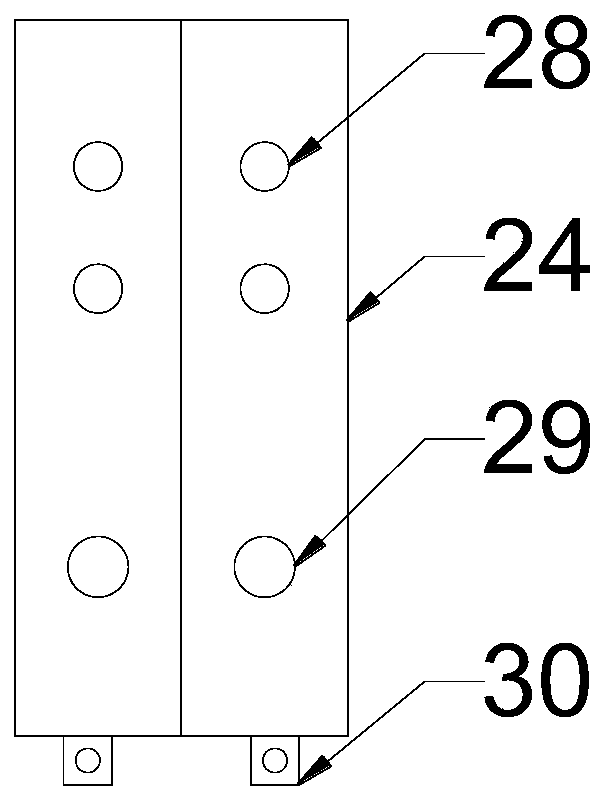

[0029] Such as figure 1 Shown: a device for monitoring microwave vacuum drying, including a drying system, a vacuum system and an image acquisition system; the drying system includes an output control system, a microwave system, a weighing system and a temperature measurement system, and the microwave system mainly Comprising a microwave chamber 9, a microwave generator 23 and a drying chamber door 25, the microwave generator 23 is located above the inner wall of the microwave chamber 9, and the microwave chamber 9 is connected with an exhaust hole 15, so that after drying The microwave chamber 9 is returned to atmospheric pressure, and an observation hole 13 is provided on the door 25. The weighing system includes a tray support 11, a tray 10 and a weighing sensor, and the weighing system is located in the microwave oven. In the middle position in the chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com