A Comprehensive Optimization Method for Centrifugal Impeller Based on Digital Twin and Reinforcement Learning

A technology of reinforcement learning and optimization methods, applied in machine learning, multi-objective optimization, design optimization/simulation, etc., can solve problems such as poor aerodynamic performance of blades, cumbersome design, simulation, manufacturing process, and inability to be considered in a unified manner, to ensure The effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] A comprehensive optimization method for centrifugal impellers based on digital twins and reinforcement learning proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings.

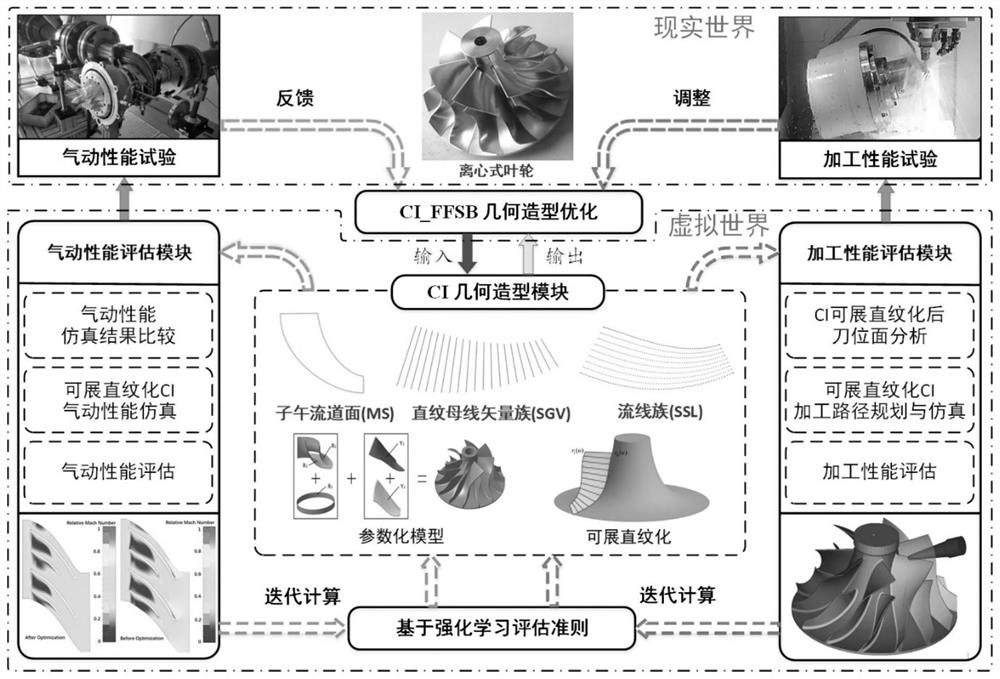

[0074]For a schematic diagram of applying the above method to an existing digital twin model, see the attached figure 1 , using the CI digital geometric model of the centrifugal impeller as the link to connect the modules of the digital twin, connect it with the processing performance optimization module and the aerodynamic performance evaluation module through data, and input the processing performance and aerodynamic performance indicators into the reinforcement learning. Learn to formulate optimization criteria to realize iterative optimization of centrifugal impeller CI blade shape. Based on the digital twin model, iteratively optimize the processing performance and aerodynamic performance of the centrifugal impeller CI with the help...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com