Quality monitoring method and device for metal cover and computer readable storage medium

A quality monitoring, metal cover technology, applied in the registration/indication quality control system, calculation, manufacturing calculation system, etc., can solve the problems of time consumption of downtime adjustment, quality change, a large number of waste products, etc., to reduce configuration and simplify quality monitoring Process, the effect of reducing experience and technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

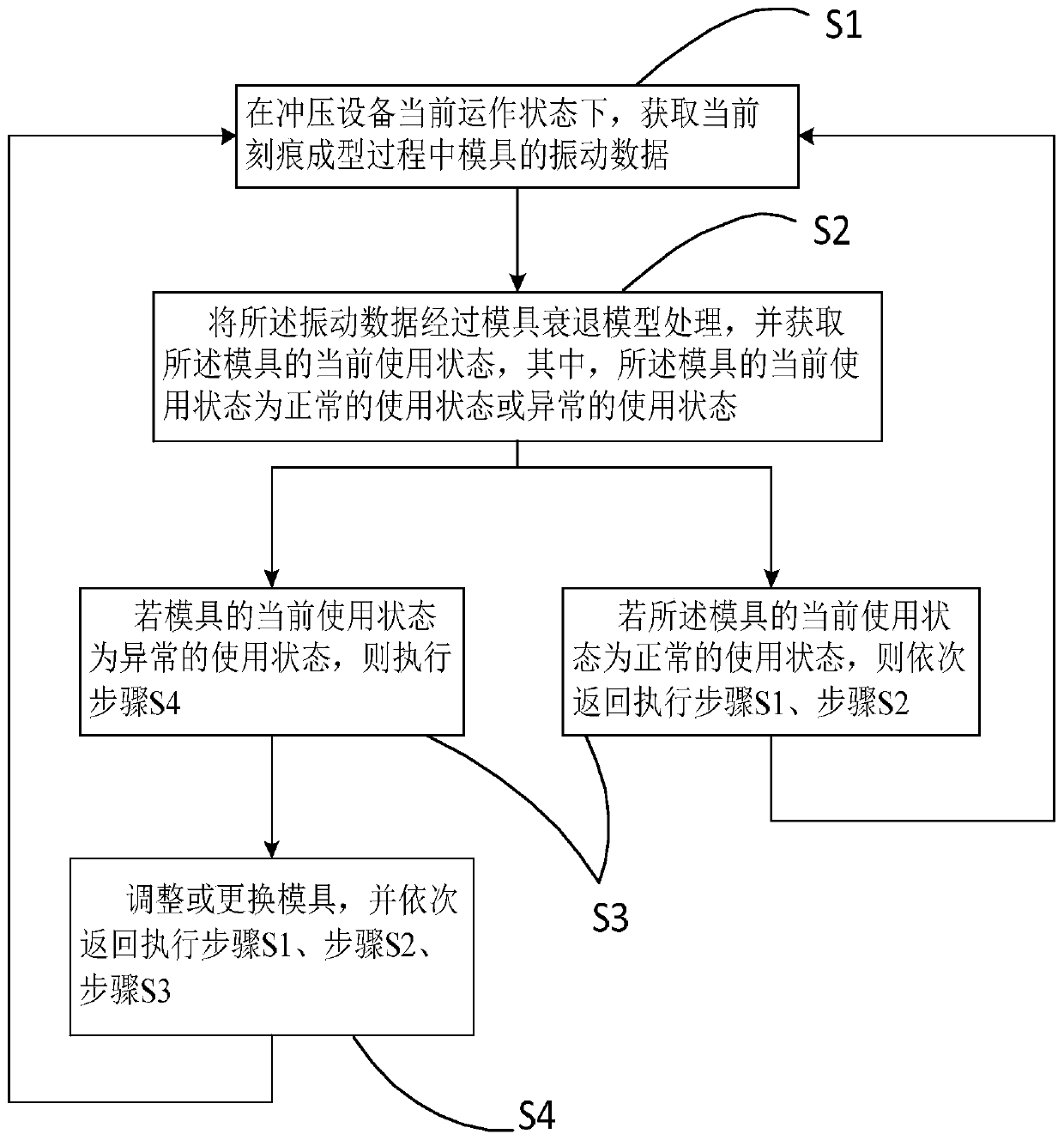

[0022] Embodiments of the first aspect of the present invention, such as figure 1 As shown, S1, under the current operating state of the stamping equipment, obtain the vibration data of the mold during the current notch forming process; S2, process the vibration data through the mold decay model, and obtain the current use state of the mold, wherein, The current use state of the mold is a normal use state or an abnormal use state; S3, if the current use state of the mold is an abnormal use state, then perform step S4, if the current use state of the mold is a normal use state , then return to execute step S1, step S2 in sequence; S4, adjust or replace the mold, and return to execute step S1, step S2, step S3 in sequence.

[0023] now combine as figure 1 The flow chart shown in the figure respectively explains the steps of the above-mentioned embodiments.

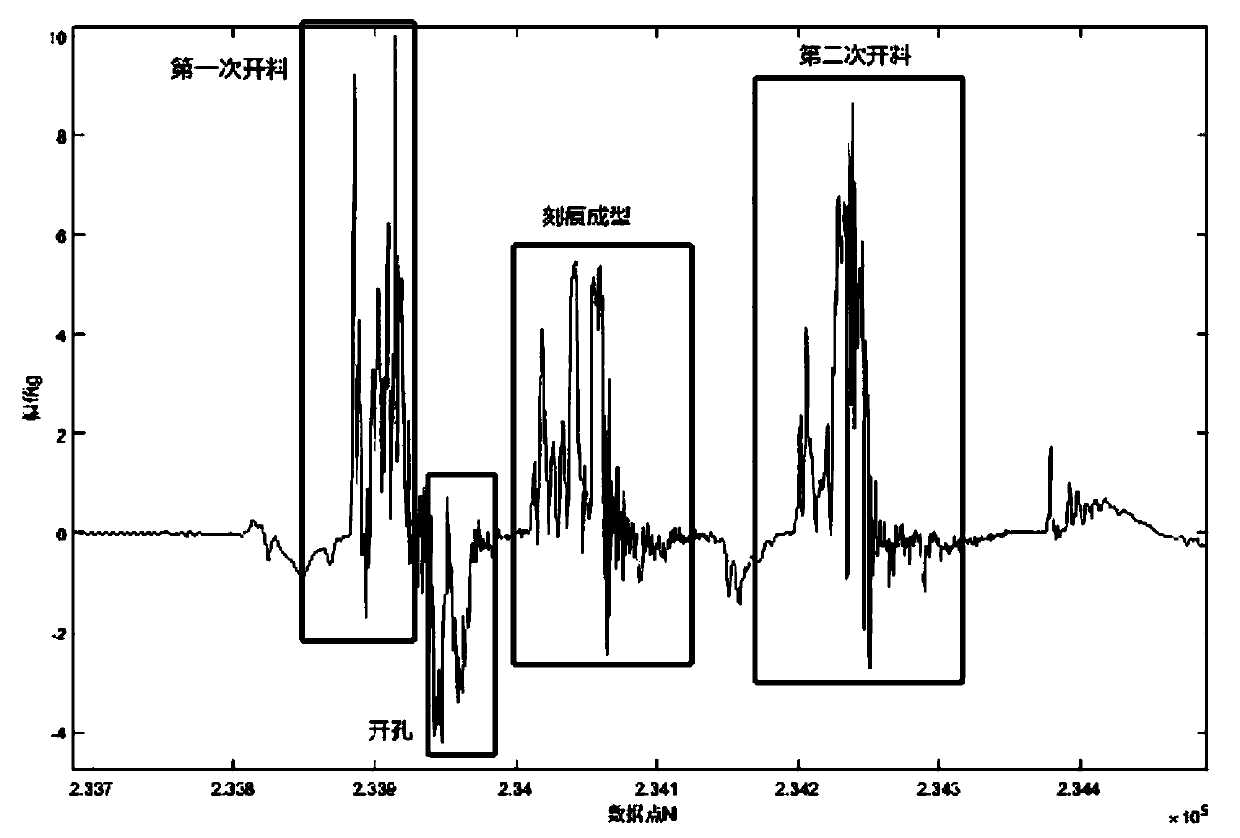

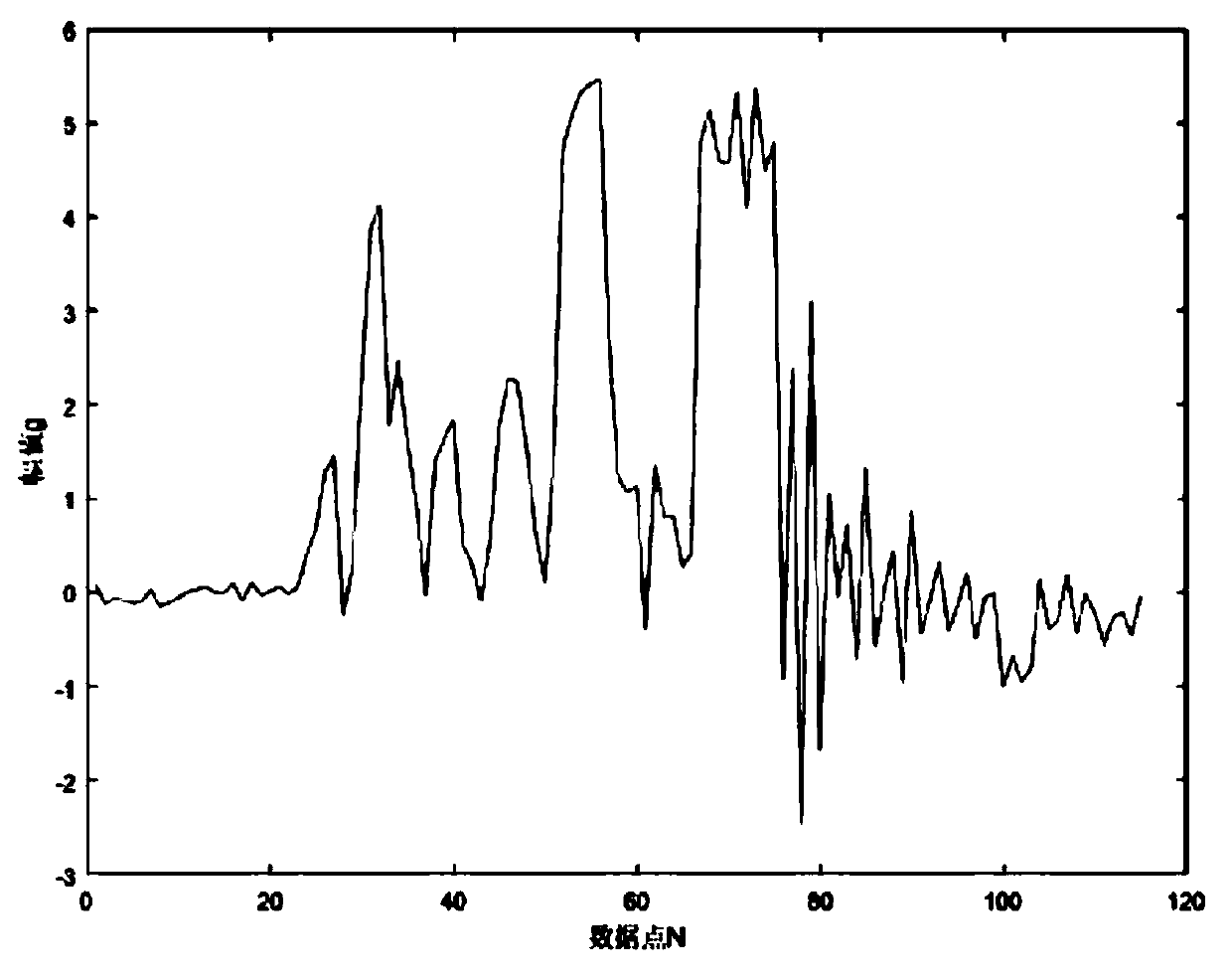

[0024] Step S1, under the current operating state of the stamping equipment, the vibration data of the mold during the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com