Double-segment type rubber roller structure

A rubber roller, consistent technology, applied in the direction of picking machines, agricultural machinery and implements, applications, etc., can solve the problems of easily crushed and easily damaged flowers, etc., to reduce damage and meet high-quality requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The conception, specific structure and technical effects produced by the present invention will be clearly and completely described below in conjunction with the embodiments and accompanying drawings, so as to fully understand the purpose, characteristics and effects of the present invention. The various technical features in the invention can be combined interactively on the premise of not conflicting with each other.

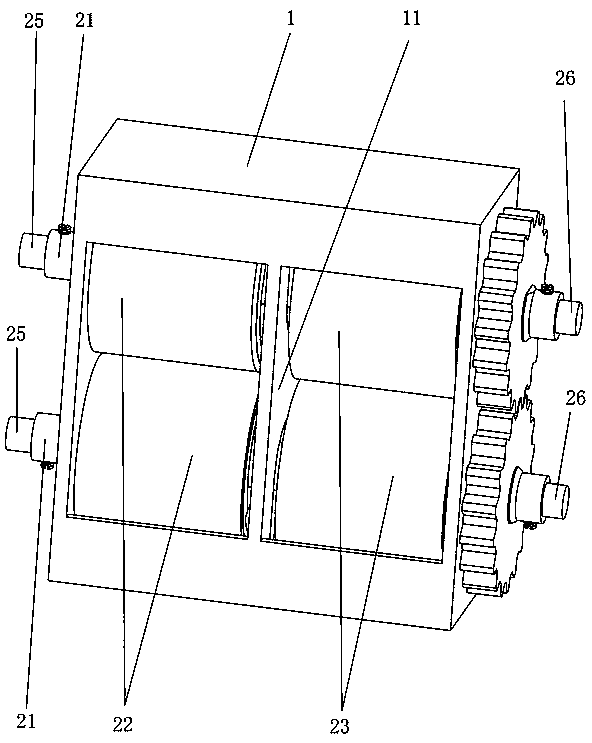

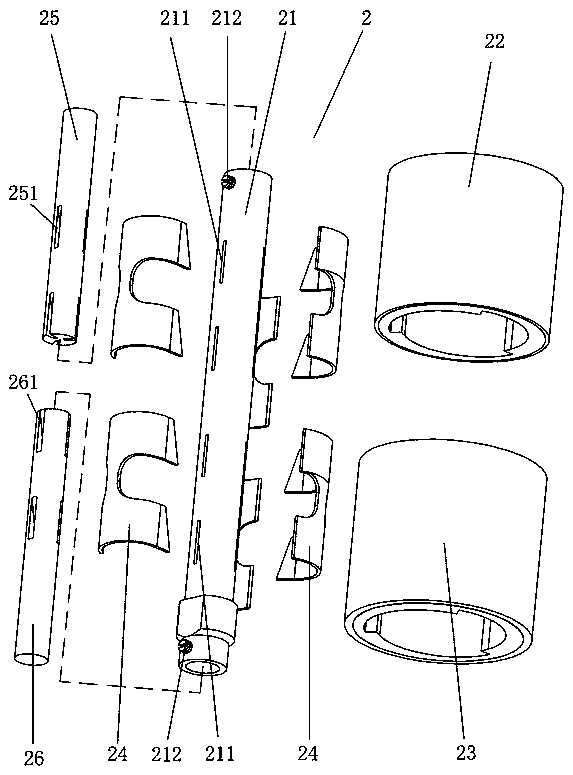

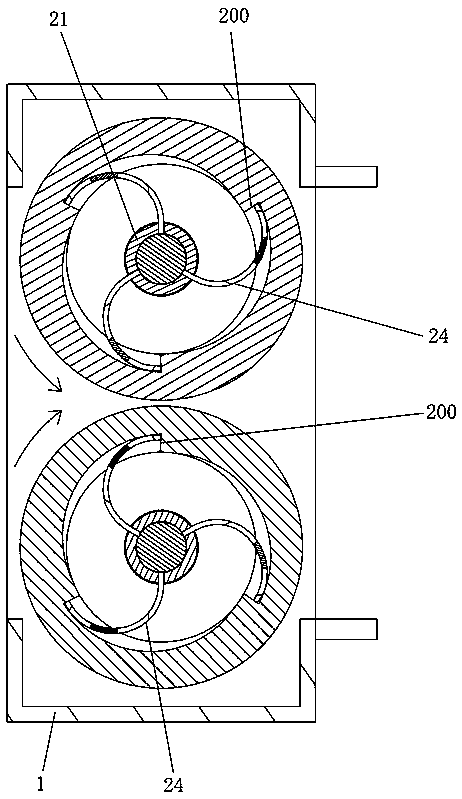

[0019] refer to Figure 1 to Figure 5 , a double-stage rubber roller structure, including two rubber rollers 2 arranged in parallel and symmetrically. The shrapnel 24 inside II23, the diameter of the rubber roller ring I22 is slightly smaller than the diameter of the rubber roller ring II23, and the rubber roller ring I22 and the rubber roller ring II23 are set side by side on the rotating shaft 21 with a gap between them. The rotating shaft 21 is provided with at least two clamping positions 211 at positions corresponding to the rubber roller ring I 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com