Composite tower plate with high flux and high defoaming efficiency

A high-throughput, composite tower technology, applied in chemical/physical/physical-chemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the high requirements for supporting tower internals, low operating flexibility, low processing capacity, etc. problem, to achieve the effect of simple structure, small pressure drop and high defoaming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

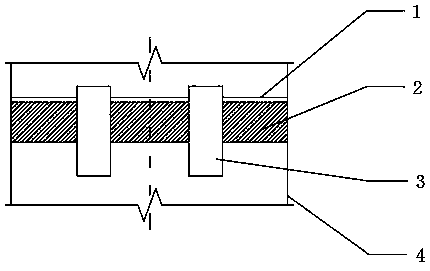

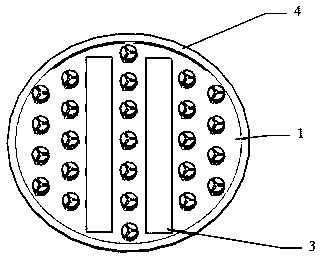

[0028] In a plexiglass tower with a plate spacing of 600 mm and a diameter of 1200 mm, install three common fixed valve trays or composite trays with high flux and high defoaming efficiency. The middle tray is the test tray, and the lower tray is the Gas distribution plate, the upper tray is a liquid distribution plate, there are 196 valve holes on the tray, the opening rate of the tray is 20.15%, the adjacent fixed valves are arranged in a regular triangle, the diameter of the valve holes is 40mm, and the center distance is 85mm, the tray uses a rectangular downcomer as the liquid circulation channel, and a mist collector is installed above the upper tray; the defoaming wire mesh packing layer is separated from the tray by a certain distance, the distance is 20mm, and the defoaming wire mesh packing material is 06Cr19Ni10, the wire diameter is 0.2mm, and the thickness of the composite defoaming wire mesh packing layer is 20mm. With air and water as the operating system, under...

Embodiment 2

[0031] In a plexiglass tower with a plate spacing of 600 mm and a diameter of 1200 mm, install three common fixed valve trays or composite trays with high flux and high defoaming efficiency. The middle tray is the test tray, and the lower tray is the Gas distribution plate, the upper tray is a liquid distribution plate; there are 196 valve holes on the tray, and the opening rate of the tray is 20.15%; the adjacent fixed valves are arranged in an equilateral triangle, the diameter of the valve holes is 40mm, and the center distance is 85mm, the tray uses a rectangular downcomer as the liquid circulation channel, and a leakage collector is installed under the lower tray. There is a certain distance between the defoaming wire mesh packing layer and the tray, the distance is 20mm, the material of the defoaming wire mesh packing is 06Cr19Ni10, the wire diameter is 0.2mm, and the thickness of the composite defoaming wire mesh packing layer is 20mm. With air and water as the operatin...

Embodiment 3

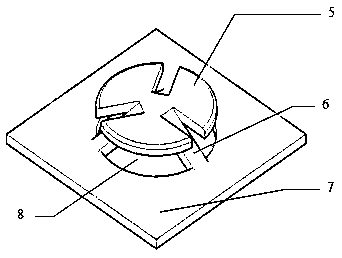

[0034] In a plexiglass tower with a plate spacing of 600 mm and a diameter of 1200 mm, install three common fixed valve trays or composite trays with high flux and high defoaming efficiency. The middle tray is the test tray, and the lower tray is the Gas distribution plate, the upper tray is a liquid distribution plate; there are 196 valve holes on the tray, and the opening rate of the tray is 20.15%; the adjacent fixed valves are arranged in an equilateral triangle, the diameter of the valve holes is 40mm, and the center distance is 85mm, the tray uses a rectangular downcomer as the liquid circulation channel. There is a certain distance between the defoaming wire mesh packing layer and the tray, the distance is 20mm, the material of the defoaming wire mesh packing is 06Cr19Ni10, the wire diameter is 0.2mm, and the thickness of the composite defoaming wire mesh packing layer is 20mm. Open 4 round holes with a diameter of 10mm on the middle tray, and insert 4 copper tubes with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com