Material distributing and defoaming device of separator

A separator and dispersion device technology, applied in the direction of evaporator accessories, etc., can solve problems such as limitations, achieve strong pressure self-adaptability, reduce costs, and simplify the design of hole spacing and quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

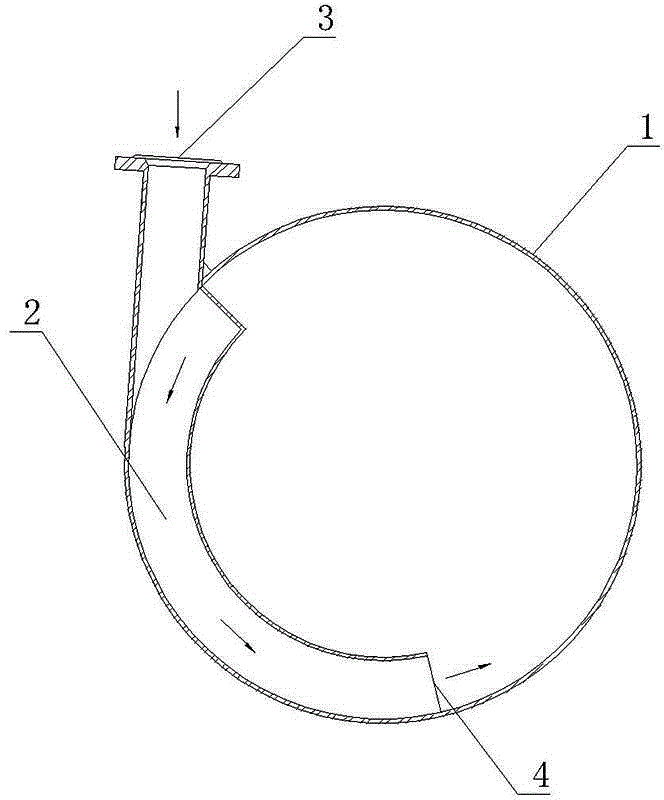

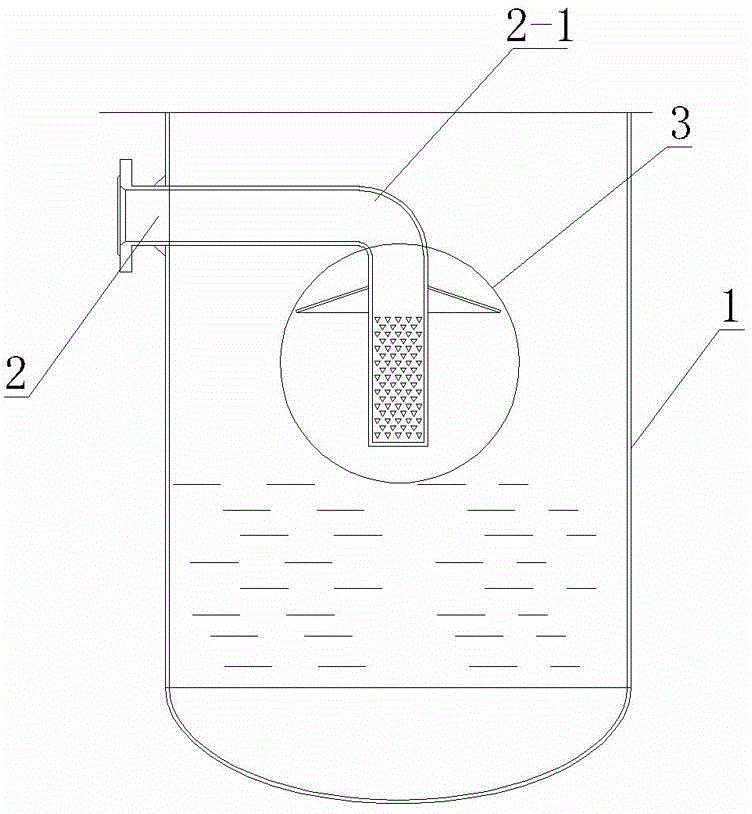

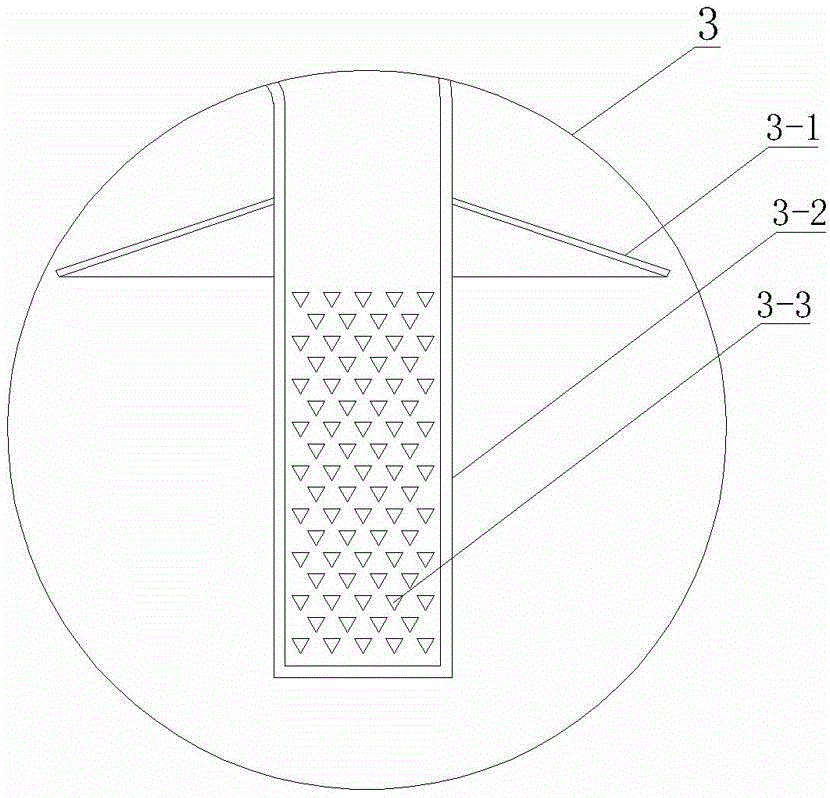

[0014] Embodiment 1: the structure of separator material distribution defoaming device provided by the present invention is as follows figure 2 and image 3 As shown, it includes a feed pipe 2 that is installed on the separator wall 1. The feed pipe 2 has a downward right-angle elbow 2-1 on the center line in the separator, and the elbow 2-1 is arranged vertically. The medium dispersing device 3 is connected, and the medium dispersing device 3 is made up of a fixedly connected tubular side wall 3-2 and a skirt-shaped outer edge 3-1, wherein the diameter of the skirt-shaped outer edge 3-1 is the diameter of the tubular side wall 3-2 top Twice the diameter, on the tubular side wall 3-2 are arranged inverted triangular spray holes 3-3, the inverted triangle is an isosceles triangle with the apex pointing down, and the number of spray holes 3-3 is calculated according to the flow volume For calculation, it is better not to spray the liquid column to the separator wall. The hori...

Embodiment 2

[0016] Embodiment 2: The structure of the material distribution and defoaming device for the separator provided by the present invention is basically the same as that of Embodiment 1, the main difference lies in the selection of structural parameters of the medium dispersion device, so the drawings are omitted. In order to adapt to a larger treatment flow, on the basis of Embodiment 1, the diameter of the skirt-shaped outer edge is increased to 3 times the diameter of the top of the tubular side wall, and the spray hole is also preferably an equilateral triangle with a side length of 10mm.

[0017] When in use, the material enters the medium dispersing device in the separator from the feed pipe, so that the spilled liquid column of the separator can be scattered more evenly, further avoiding the foam generated by splashing, which can allow larger per unit time than the previous design. The amount of feed material not only reduces the discharge of condensed water COD and the los...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com