A Roll Gap Adjustment Method for Roll Gap of Roller Crusher

A technology of a roll crusher and an adjustment method, which is applied in the field of roll gap adjustment of the roll gap of the roll crusher

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

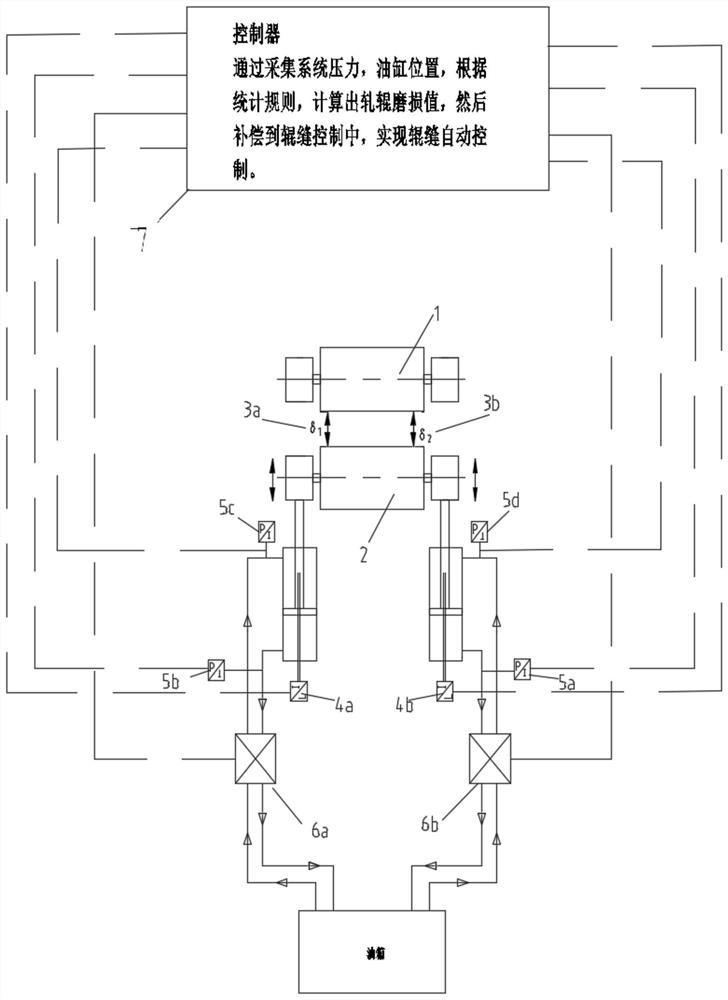

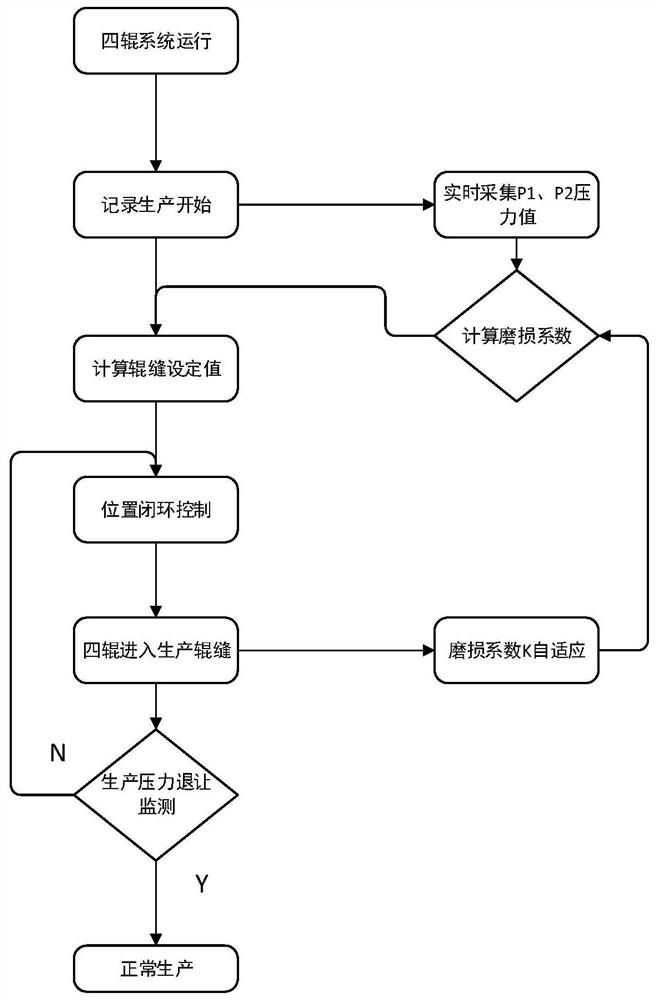

[0035] The roll gap adjustment method of a roll crusher roll gap in this embodiment is applied to such as figure 1 In the crusher shown, the material is thrown into the gap between the fixed roller 1 and the moving roller 2 and passes through, and the material is squeezed and crushed by the fixed roller 1 and the moving roller 2 when passing through; The first regulating valve 6a has two oil pipes connected with the hydraulic station respectively, and the first regulating valve 6a also has two oil pipes connected with the rod chamber and the rodless chamber of the first oil cylinder respectively, and the piston of the first oil cylinder The rod is connected with the first bearing seat of the moving roller 2. When the first oil cylinder acts, it drives the moving first bearing seat to move, causing the material between the moving roller 2 at the end of the first bearing seat and the fixed roller 1 to be squeezed, causing The load F1 of the first oil cylinder changes; the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com