Knurling process for bearing position interference assembly and knurling shaft

A technology of bearing position and knurling, which is applied in the field of shaft processing, can solve problems such as easy loosening of bearings, unusability, waste of manpower and material resources, etc., and achieves the effects of easy processing, low manufacturing cost, and reduced scrapping probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

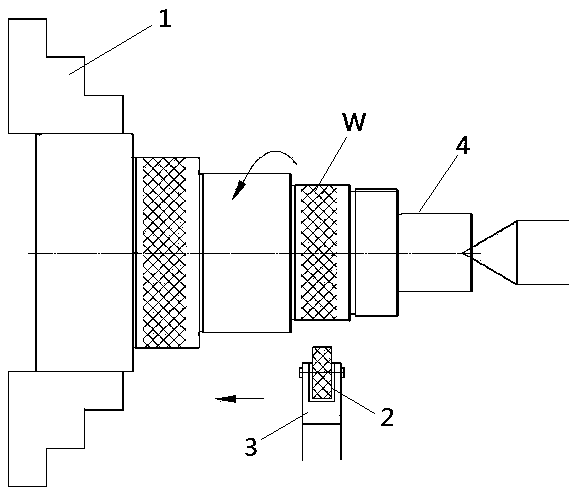

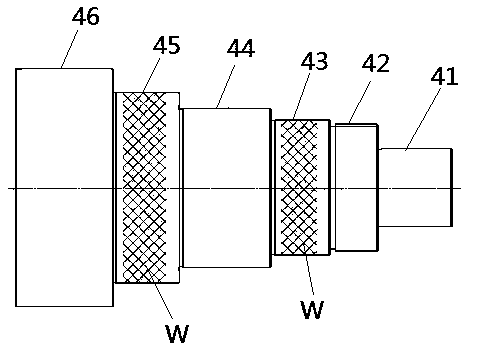

[0019] Figures 1 to 2 It is a structural schematic diagram of the knurling process and the knurling shaft of the present invention.

[0020] During the manufacturing process of the shaft, it is often the case that the entire shaft cannot be used due to the small machining size of the bearing position on the shaft for installing the bearing. In order to ensure that the shaft can continue to be used, in the prior art, electroplating or electric welding and turning methods are usually used to increase the size of the bearing position of the shaft, but these methods are generally complicated in process and relatively difficult to operate. The invention provides a knurling process for bearing interference assembly, that is, a knurling process for knurling the surface of the bearing installation position of the shaft. The bearing knurling process c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com