Automatic warehousing system

A storage system and track technology, applied in the field of logistics management system, can solve the problems of insufficient sorting speed and occupied storage space, etc., and achieve the effect of flexible and convenient access, simple structure, and easy maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

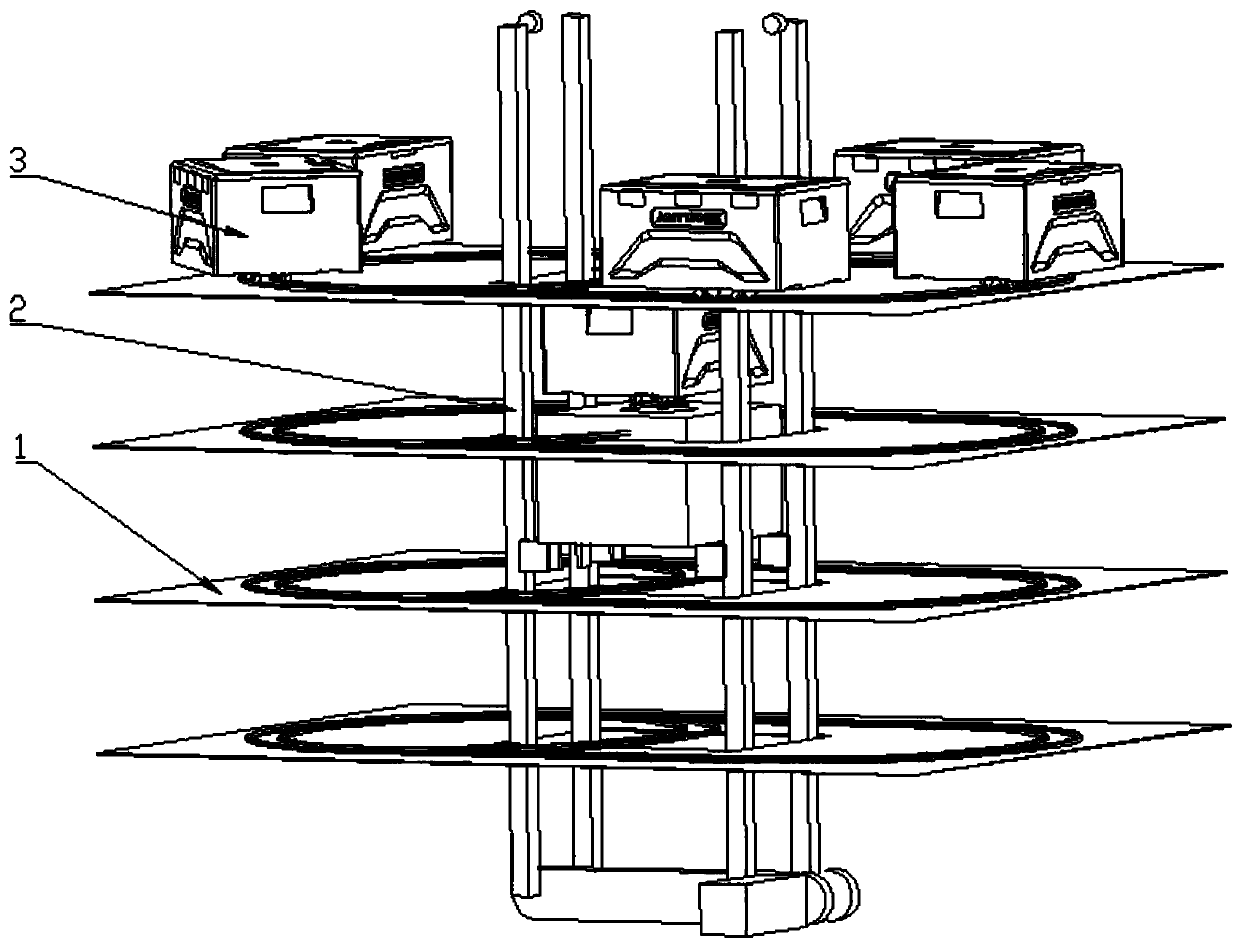

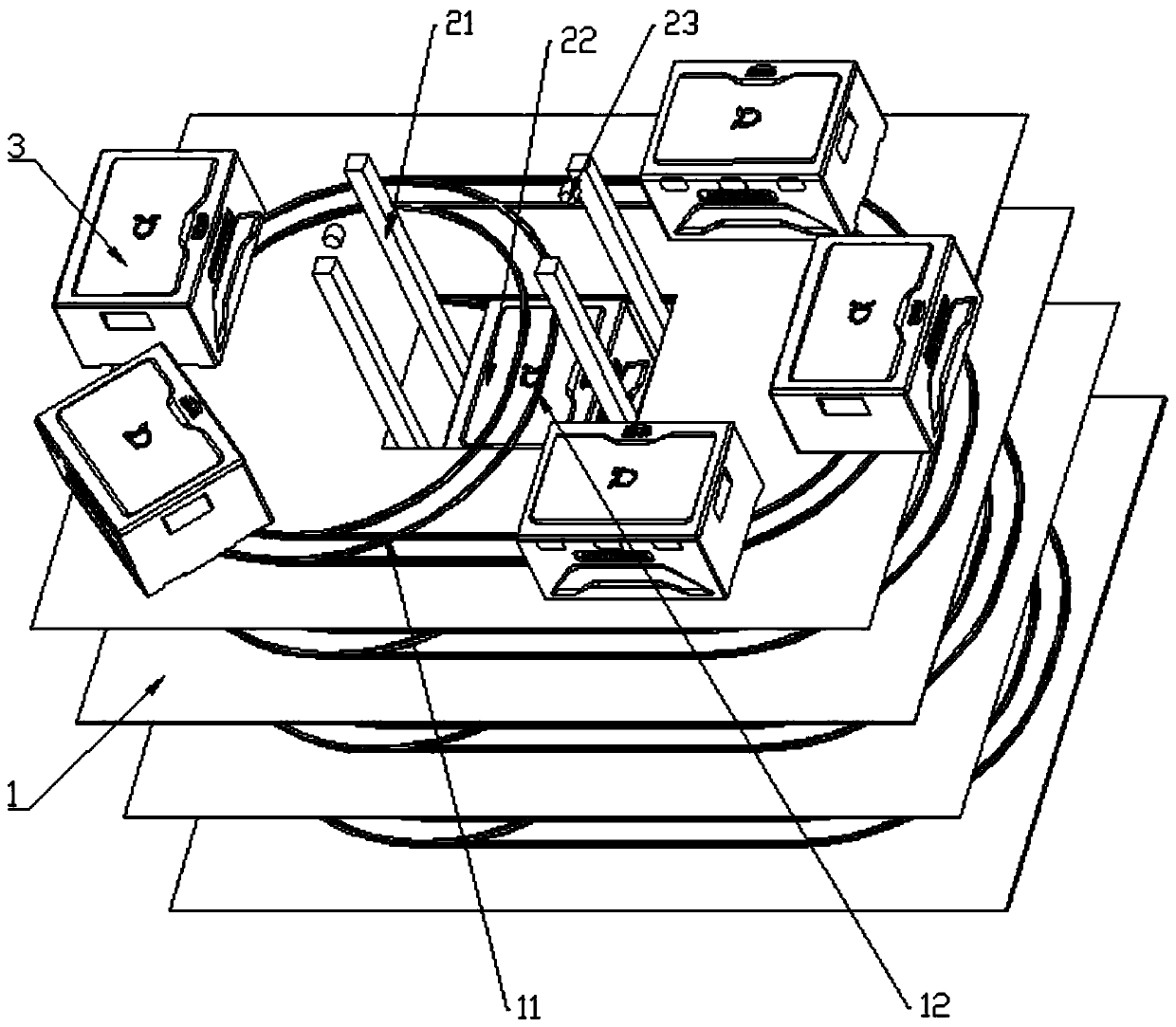

[0064] Such as figure 1 — Figure 9 , Figure 12 As shown, N floors (N≥1) are set on the running surface here, and circular tracks are set on each running surface. The running direction shown in the figure is counterclockwise, and the transfer vehicle stops on a certain floor with the elevator. On the running surface of the conveyor belt, after the moving track is docked with the fixed track on the surface, the transfer vehicle runs on the fixed track to deliver the items to the designated position. The fixed points for receiving and stocking can be set around the running surface.

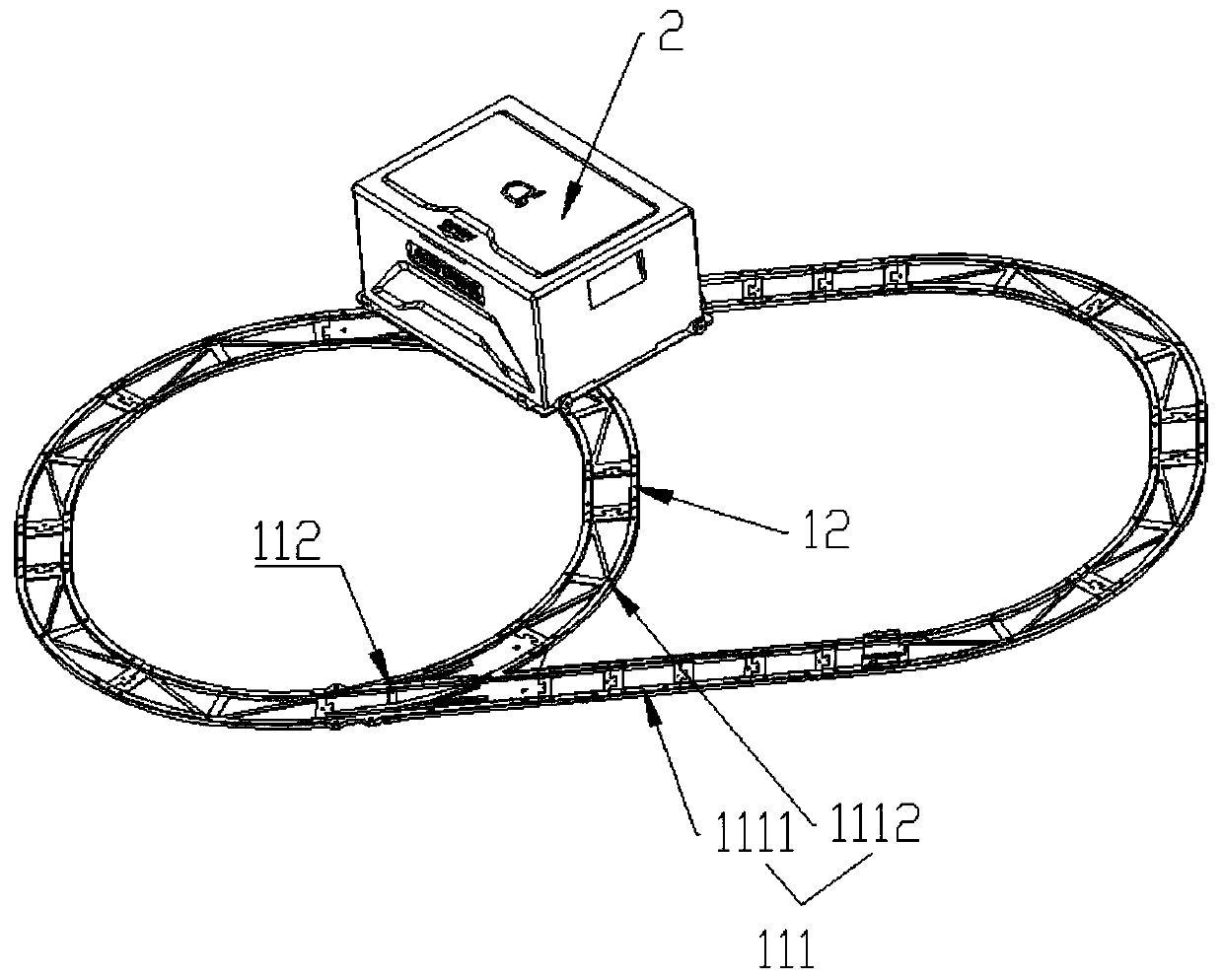

[0065] After the transfer is completed, when the transfer vehicle is at the position of the "herringbone" fork, the change track 112 plays a role and pulls the switch block 1123, so that the first guide bar and the second guide bar are on the fixed track with the pin as the axis. Rotate upwards to "move" the transfer vehicle from one direction of the track to the other direction, the transfer ve...

Embodiment 2

[0068] Such as Figure 10 , Figure 11 As shown, "Y"-shaped rails are set on both sides of the elevator here. This method is adopted for the storage space of small spaces. The car runs on the fixed track to deliver the article to the designated position; or changes direction by changing the direction of the track 112, and transfers it to the track in the other direction.

[0069] Here, the transfer vehicle reciprocates on the track in each direction, quickly arrives at the delivery point or returns to the elevator to complete replenishment or change floors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com