Gearbox release shifting fork supporting bolt with ball head part made of POE material and preparation method of gearbox release shifting fork supporting bolt

A technology for separating shift forks and supporting bolts, which is applied in the direction of screws, clutches, mechanical equipment, etc., can solve the problems that cannot meet the overall demand for lightweight automobiles, affect the control accuracy of gearboxes, and have short service life of supporting bolts, and achieve noise reduction, Excellent mechanical properties and reduced replacement times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

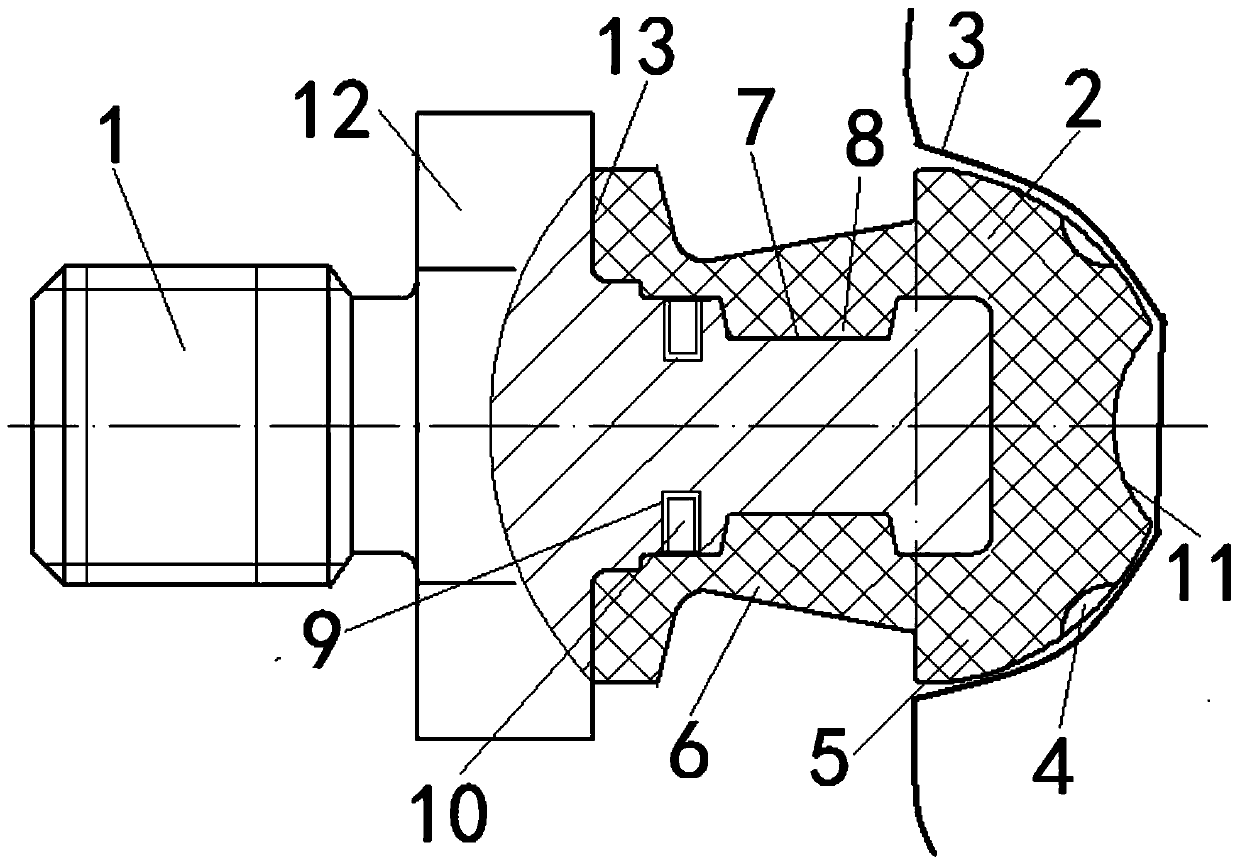

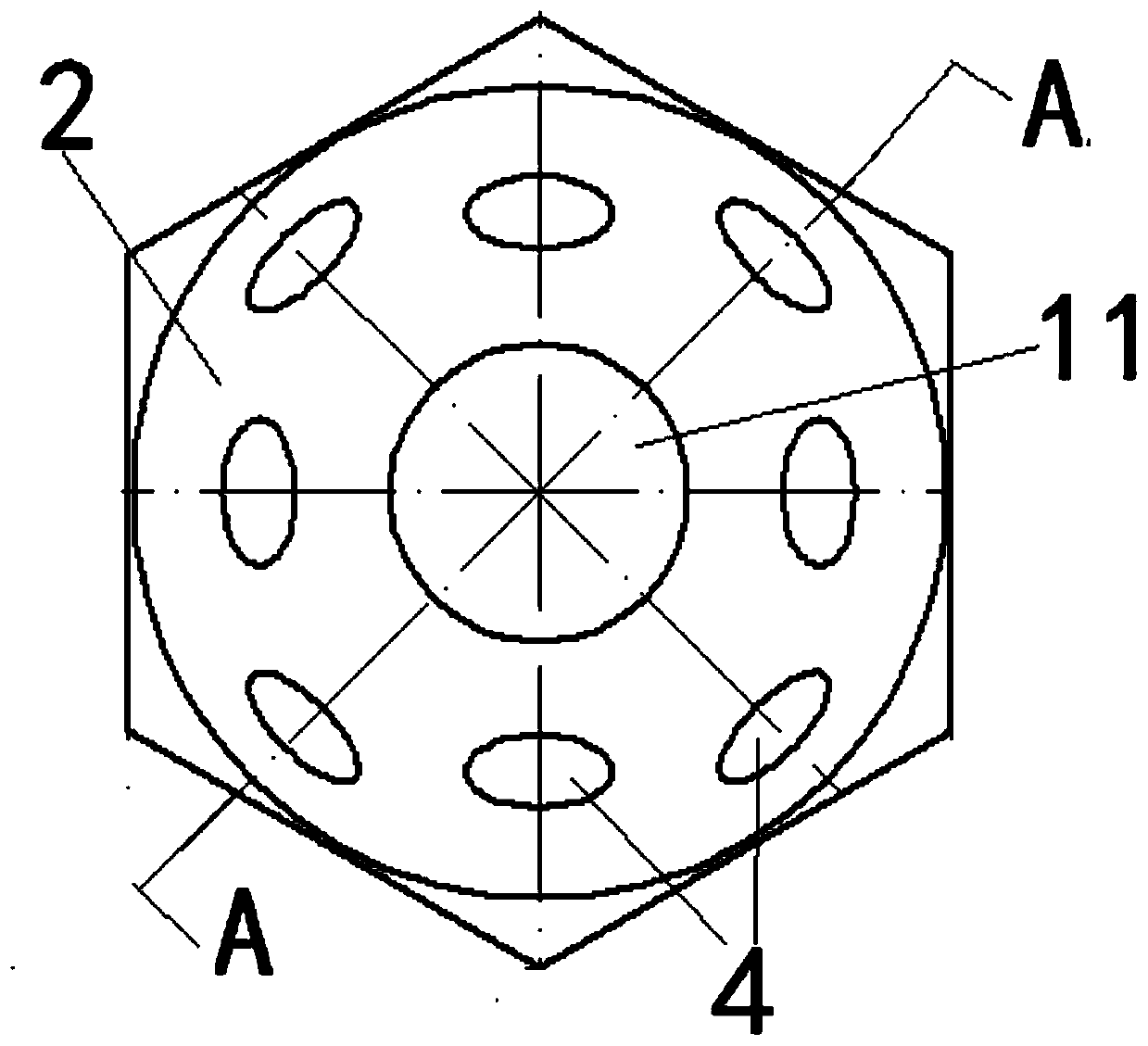

[0039] A transmission fork support bolt whose ball head is made of POE material, the material of the ball head 2 of the bolt is POE and glass fiber accounting for 18% of the POE mass, as shown in the attached Figure 1~3 shown.

[0040] The bolt ball head 2 is sleeved on one end of the bolt body 1, and the external connecting sleeve 3 is connected with the movable sleeve of the bolt ball head, and the external connecting sleeve 3 is connected with the separating shift fork body of the gearbox.

[0041]With the above-mentioned structure, when designing or manufacturing the supporting bolts for the gearbox release shift fork (support pins for the gearbox release shift fork), after the bolt body 1 is processed and shaped, the bolt body 1 is then put into the mold and POE is directly injected onto the bolt body 1 A bolt ball head 2 is formed on the top, the bolt body is made of metal material, and the bolt ball head is made of plastic material. In this way, when the transmission ...

Embodiment 2

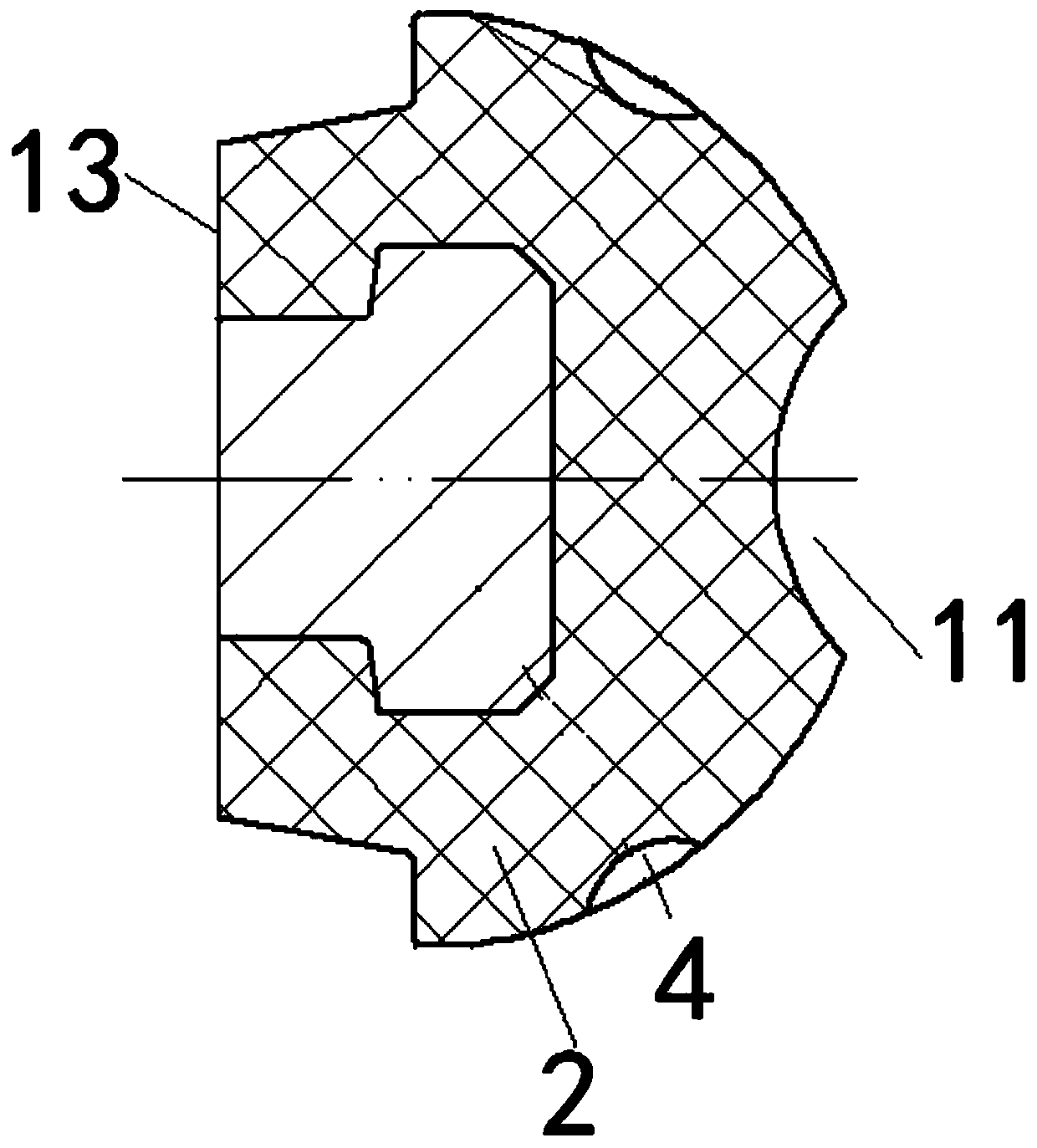

[0061] A gearbox separation shift fork support bolt whose ball head is made of POE material. The raw materials of the ball head 2 of the bolt are POE, glass fiber and molybdenum disulfide, and the quality of the glass fiber is 20% of POE. The mass of molybdenum disulfide is 1.0% of the mass of POE. as attached Figure 4 shown.

[0062] The bolt ball head 2 is sleeved on one end of the bolt body 1, and the external connecting sleeve 3 is connected with the movable sleeve of the bolt ball head, and the external connecting sleeve 3 is connected with the separating shift fork body of the gearbox.

[0063] A groove 4 is arranged on the top end of the bolt ball head 2 . Lubricating oil can be stored in the groove to improve the lubricating effect and reduce wear and noise.

[0064] One end of the bolt body 1 where the bolt ball head 2 is installed is provided with a boss plane 15. , When the transmission fork support bolt is impacted by an external force due to the operation of ...

Embodiment 3

[0078] A gearbox separation shift fork support bolt with a ball head made of POE material, the ball head 2 of the bolt is POE, glass fiber and molybdenum disulfide, the quality of the glass fiber is 22% of POE, and the two The mass of molybdenum sulfide is 1.8% of the mass of POE. as attached Figure 5 shown.

[0079] The bolt ball head 2 is sleeved on one end of the bolt body 1, and the external connecting sleeve 3 is connected with the movable sleeve of the bolt ball head, and the external connecting sleeve 3 is connected with the separating shift fork body of the gearbox.

[0080] The top end of the bolt ball head 2 is a planar structure 14 , and after the bolt ball head 2 is assembled with the outer connecting sleeve 3 , a cavity can be formed between the planar structure 14 and the outer connecting sleeve 3 .

[0081] The bolt ball head 2 includes a body portion 5 and a connection portion 6 , the body portion 5 and the connection portion 6 are integrally structured, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com