Flexible gear and harmonic reducer

A flexible gear and gear technology, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of affecting the life of the reducer, damage to the arc transition section, etc., to improve reliability, increase The effect of transition thickness and large promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

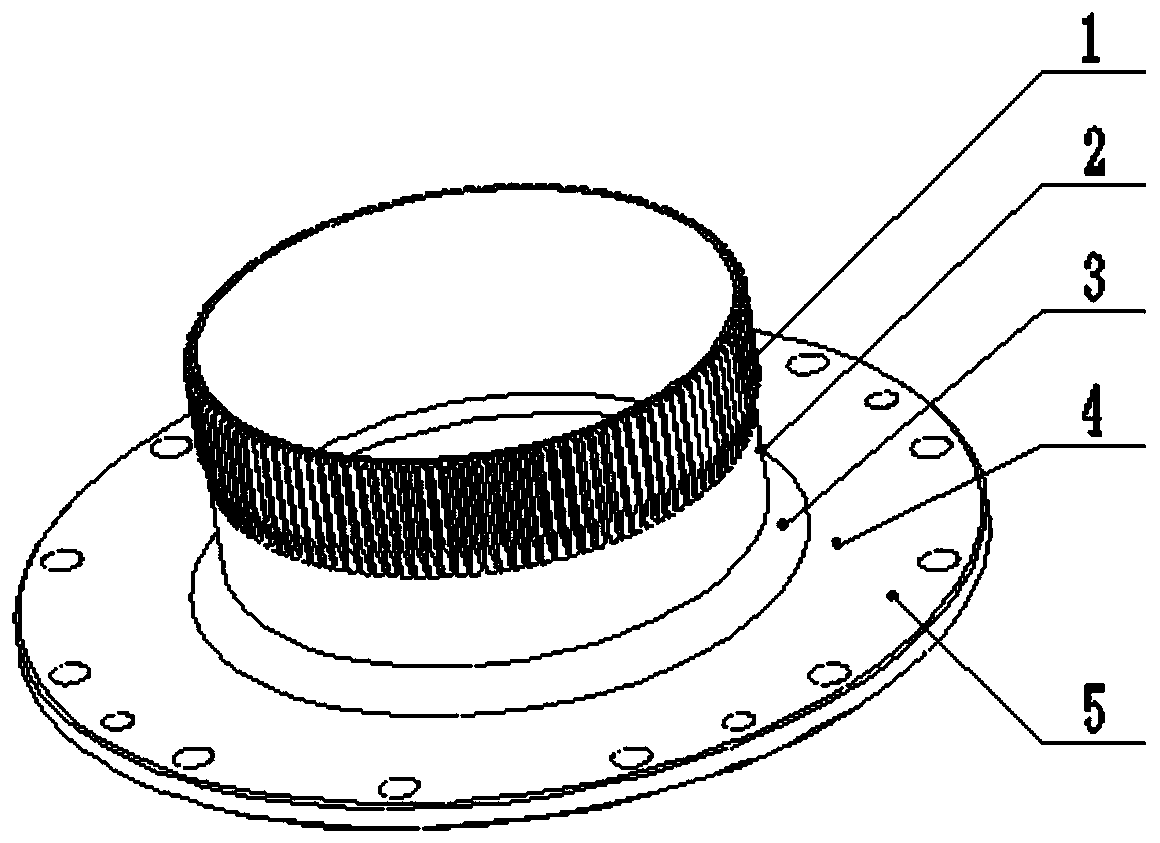

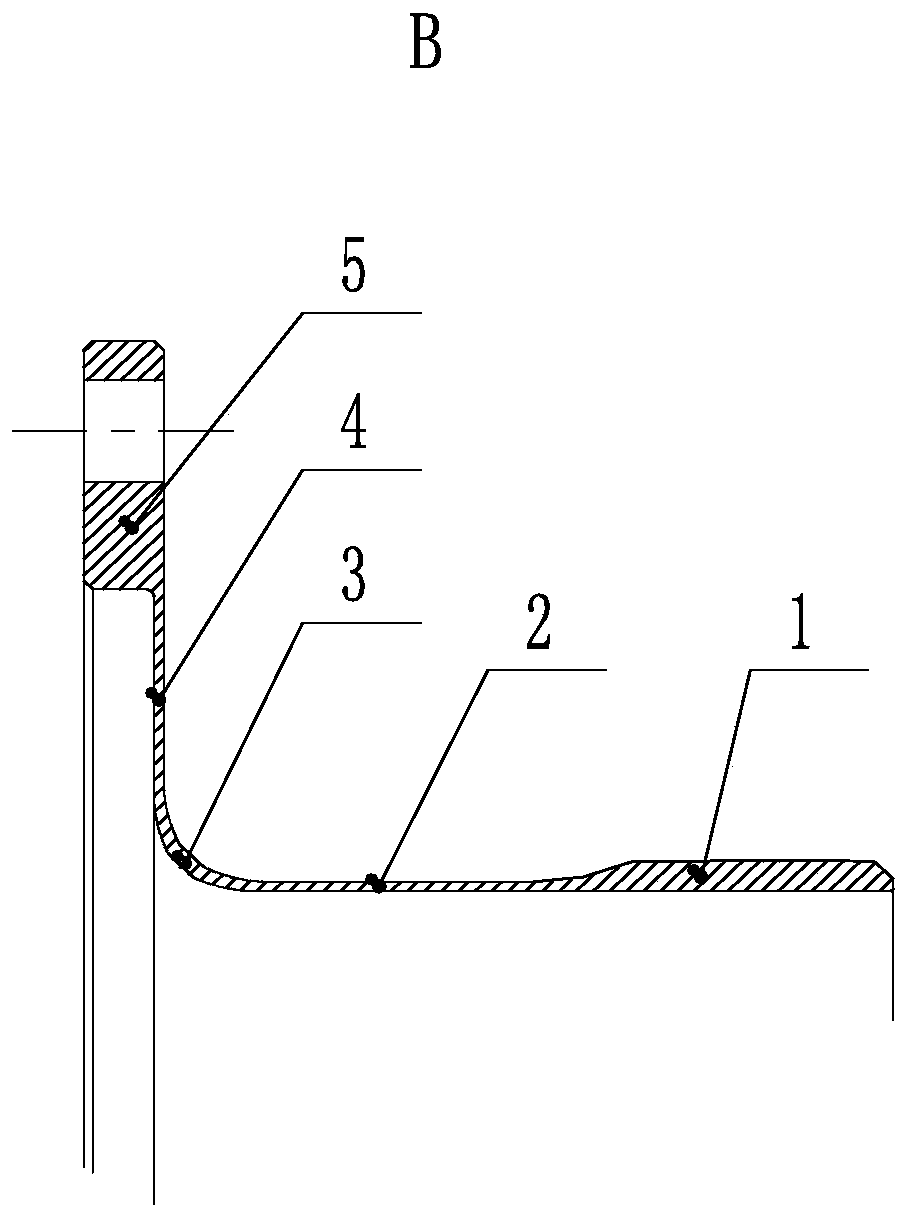

[0038] like Figure 1-4 As shown, the present invention provides a flexible gear, which includes:

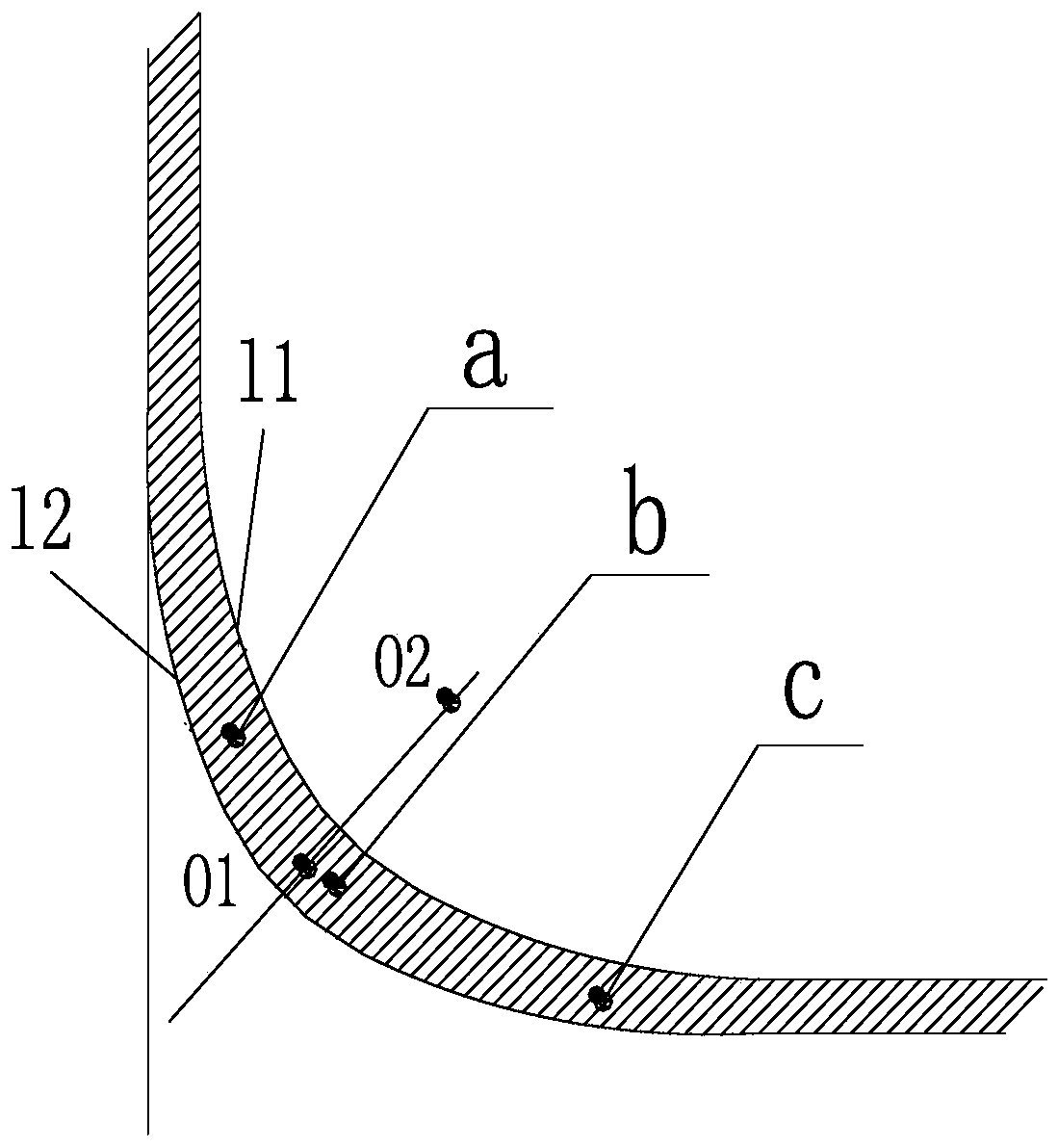

[0039] It includes a gear segment 1, a flange segment 5 and a corner segment 3 between the gear segment 1 and the flange segment 5, and the corner segment 3 is a curved segment with variable thickness transition; the variable thickness transition The curved section includes a first variable thickness section a relatively close to the flange section 5 and a second variable thickness section c relatively close to the gear section 1, and is connected to the first variable thickness section a and the second Transition section b between variable thickness sections c.

[0040] The present invention changes the circular arc transition section of the flexspline from the original uniform wall thickness design to the variable wall thickness design, effectively increasing the transition thickness of the flexspline's thin-walled section and the visor section. Compared with the ordinary fle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com