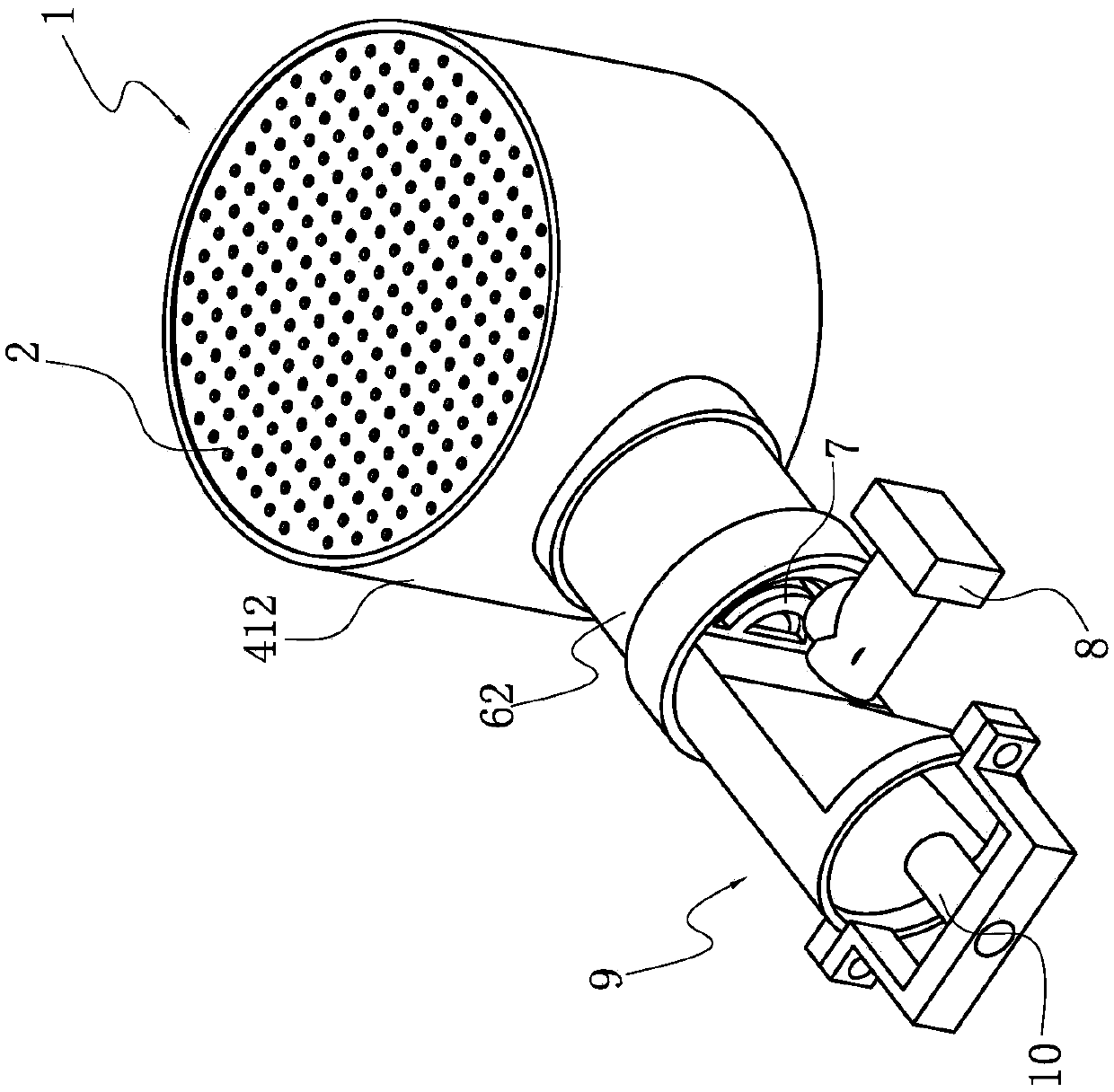

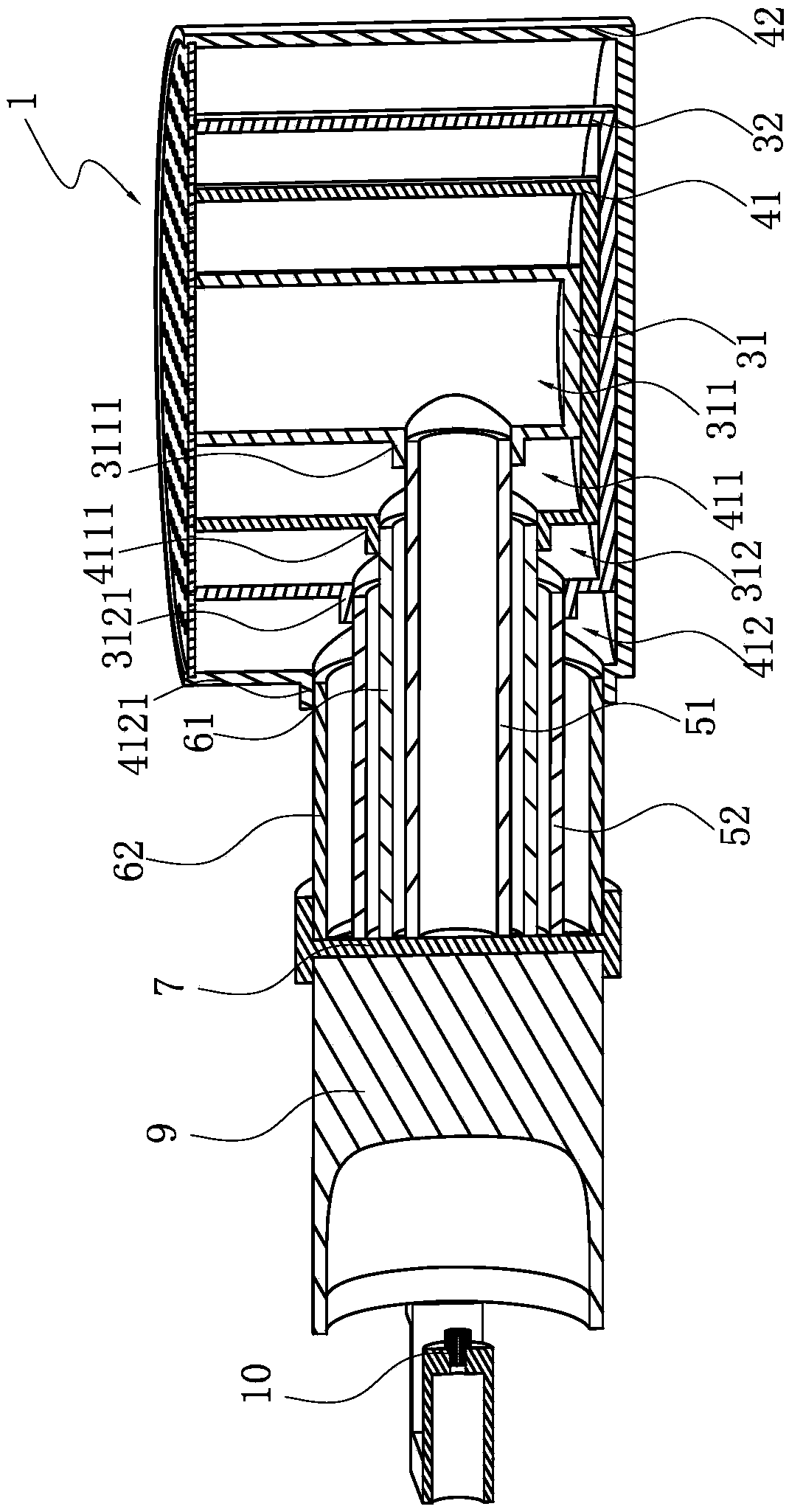

Burner for gas stove

A technology for burners and gas stoves, which is applied in the direction of gas fuel burners, burners, and incombustible liquid/gas transportation, etc. It can solve the problems of wasting gas, inability to conduct uniform heat, and poor combustion efficiency, and achieve uniform flow rate and increase in Combustion efficiency and heat load improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

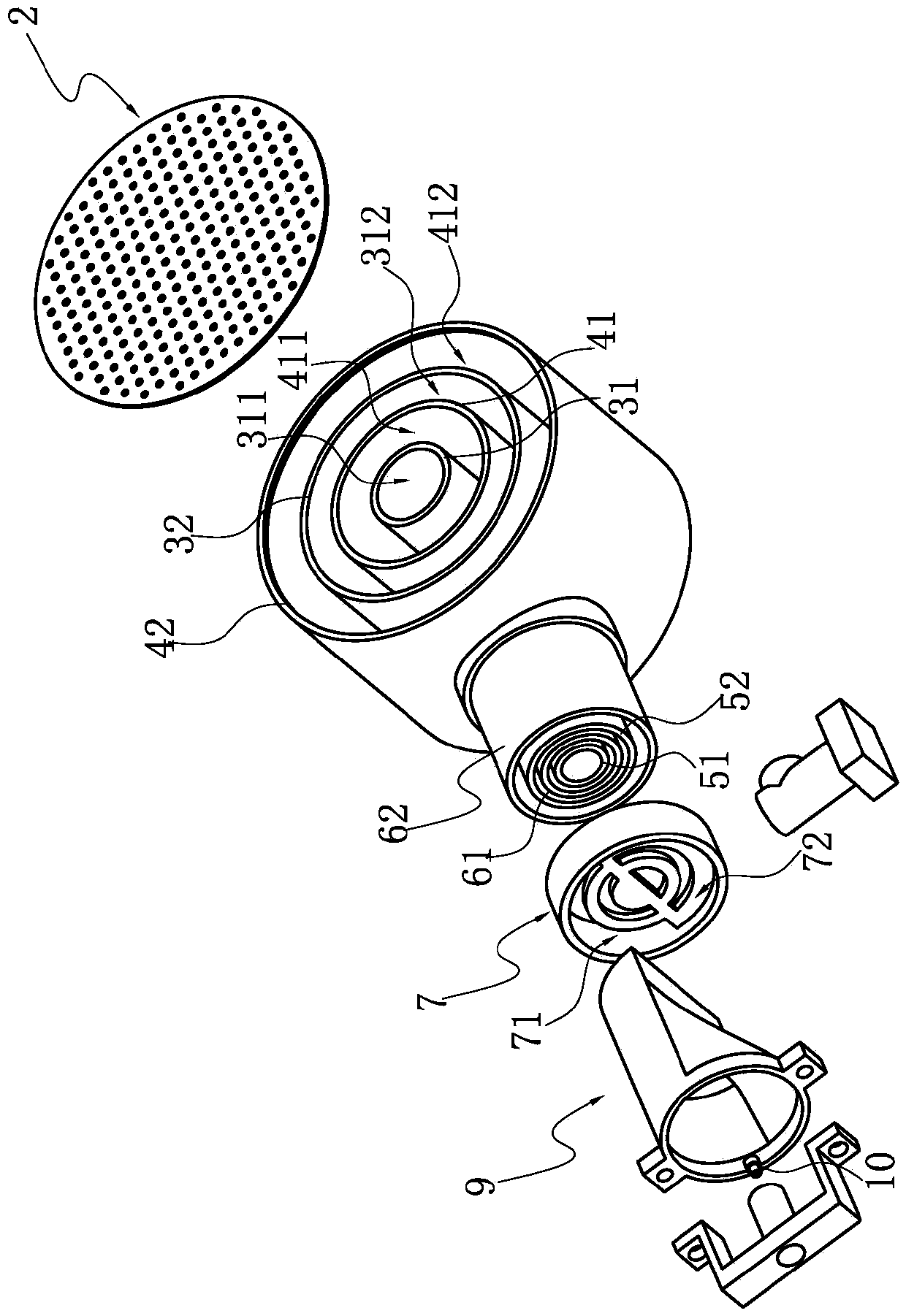

[0032] The structure is basically the same as that of Embodiment 1, the only difference is that the first air pipe 51 and the second air pipe 52 are located on one side of the burner body 1, wherein the second air pipe 52 is arranged around the first air pipe 51, and the first The air pipe 51 is arranged transversely through the peripheral gas chamber 412, and the second air pipe 52 communicates with the first air pipe 51 and is connected with the air supply part 8 such as a blower, so that air can enter the peripheral air chamber 312 and the central air chamber 311; The gas pipe 61 and the second gas pipe 62 are located on the other side of the burner body 1, wherein the second gas pipe 62 is arranged around the first gas pipe 61, the first gas pipe 61 is arranged transversely through the peripheral air chamber 312, and the second gas pipe The pipe 62 is connected with the injection pipe 9 and the nozzle 10 together with the first gas pipe 61, so that the gas enters the periph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com