Multi-series-parallel battery module anomaly detection method

A battery module and anomaly detection technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of accurately judging the internal resistance and capacity abnormality of multi-series parallel battery modules, so as to save test time, The effect of improving efficiency and avoiding rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

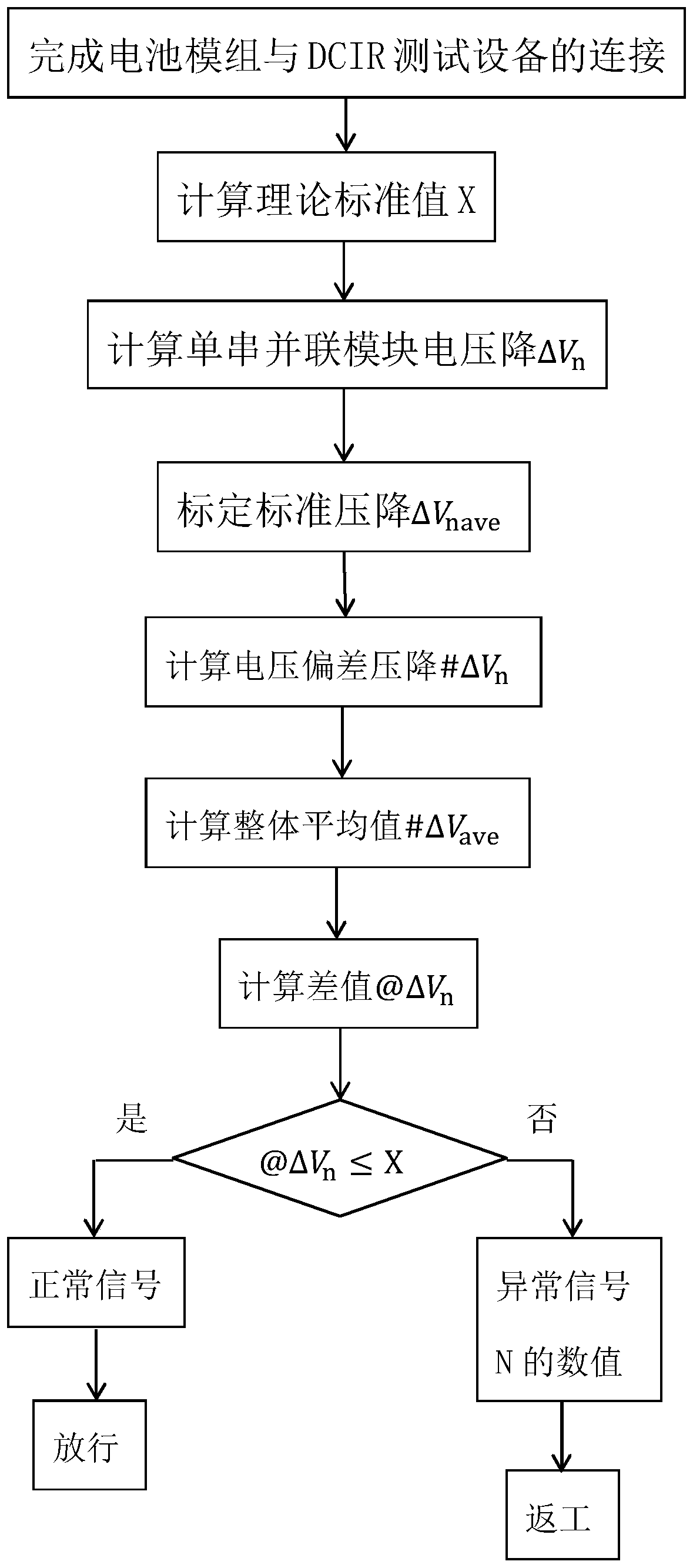

[0064] A method for abnormal detection of multi-series parallel battery modules, such as figure 1 shown, including the following steps:

[0065] S1: Complete the connection between the battery module and the DCIR test equipment.

[0066] S11: Connect the positive and negative poles of the battery module that has completed wire welding to the DC internal resistance testing equipment.

[0067] A multi-parallel battery module is composed of multiple parallel modules connected in series, and a parallel module is composed of multiple batteries connected in parallel. After the wire welding to the battery module is completed, connect the DC internal resistance testing equipment for testing, and the DC internal resistance testing equipment can charge and discharge the battery module. The test is carried out during the preparation process of the battery module, which avoids the trouble of disassembling and reworking after the old battery system is found after the battery module is as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com