Stretching mechanism-supported double-side array large-area flexible solar cell wing

A flexible solar cell and stretching mechanism technology, which is applied in the aerospace field, can solve the problems of limited deployment area and stiffness of flexible solar cell wings, poor dynamic characteristics and bearing capacity, and insufficient utilization, and achieves strong designability and power. The effect of large weight ratio and small wrapping envelope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

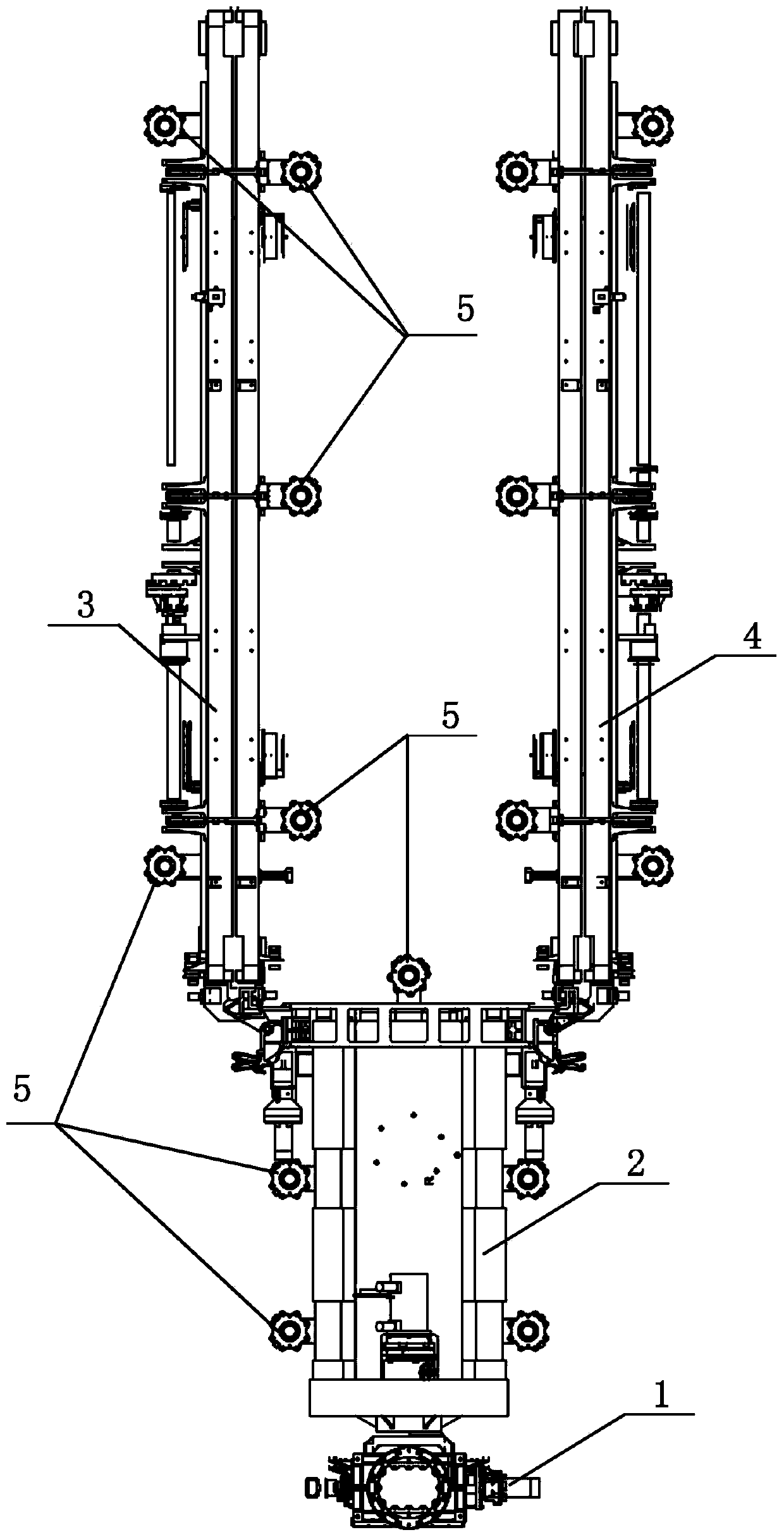

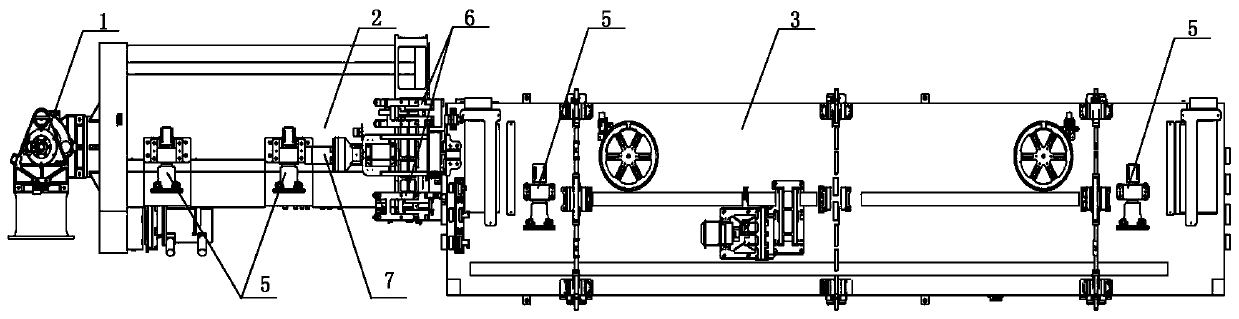

[0079] Due to the space limitation of the vehicle and the large overload during the launch process, the solar wing needs to go through the process of first retracting and then unfolding. In view of the harsh space environment and the deployment requirements of tens or even hundreds of square meters, after the spacecraft is in orbit, the solar wing Wing deployment and locking are extremely important. The thinness and large size of flexible solar wings greatly increase the difficulty of designing the deployment mechanism. Traditional flexible solar cell wings often have complex mechanical structures, complex deployment processes, unstable driving processes, and easy structural vibration damage. question. Therefore, in order to meet the needs of space missions, there is an urgent need for a flexible solar wing structure that meets the requirements of large scale, high precision, high stiffness, and easy control, and supports it from the aspects of reducing structural complexity, ...

Embodiment 2

[0114] In this embodiment, in order to release the extra stress suffered by the box during the unlocking process and improve the bearing capacity, the stretching mechanism supports the large-area flexible solar battery wings of the double array and is also provided with several auxiliary sliding devices 8, and several auxiliary sliding devices 8 is installed symmetrically on the top of the stretching mechanism 2, and is connected with the upper box of the flexible solar cell array. When the constraint release mechanism of the flexible solar cell array is unlocked and released, the upper box and the lower box are separated, and the auxiliary sliding device 8 is used to release the upper box during the process of unlocking and releasing the upper box and the lower box. the force suffered.

[0115] preferred, such as Figure 18 In particular, the auxiliary sliding device 8 can be installed in the top frame structure of the stretching mechanism. Among them, such as Figure 19 ,...

Embodiment 3

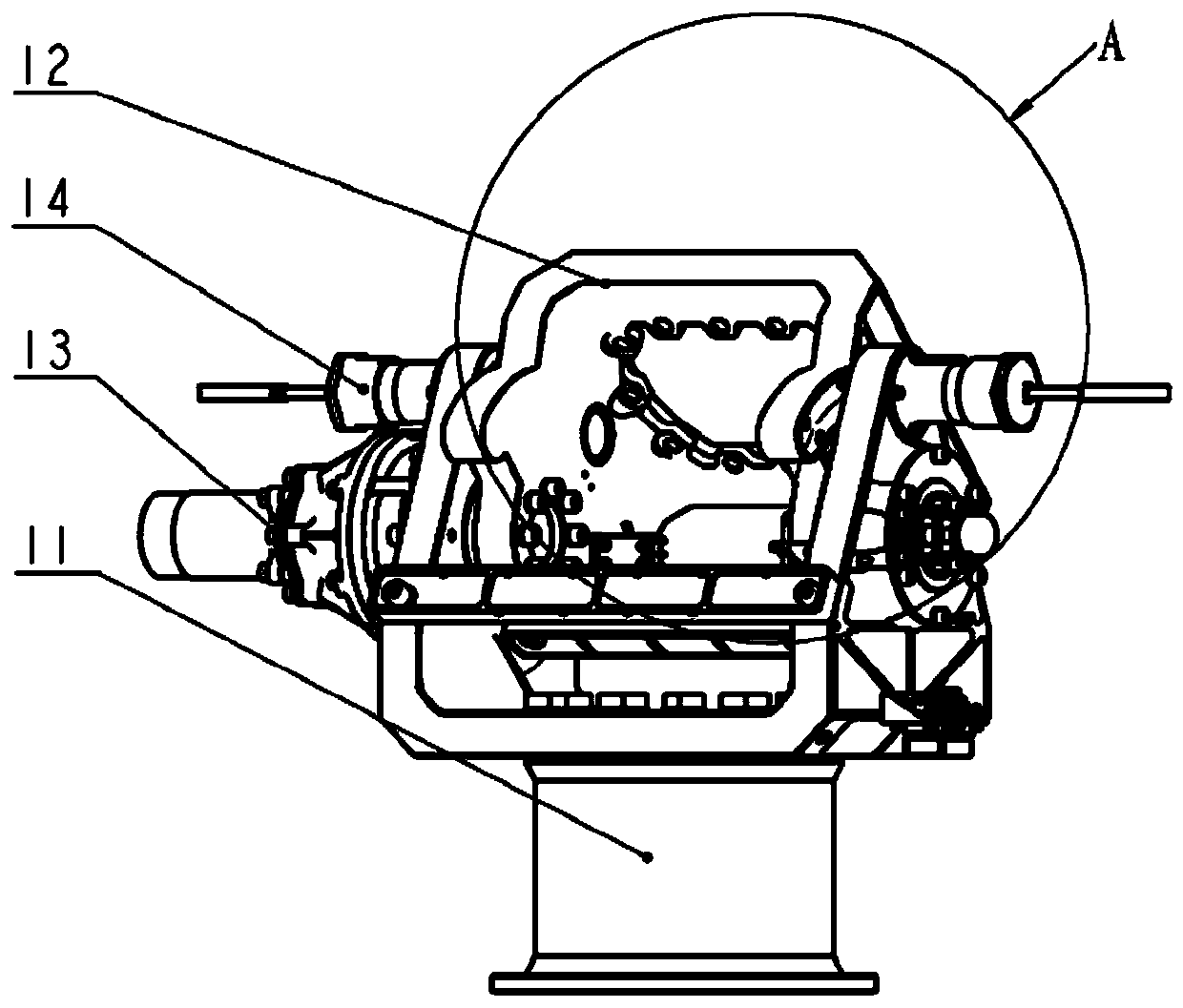

[0118] In this embodiment, the upper box unfolding locking mechanism 6 is used as a passive mechanism, and the lower box unfolding locking mechanism 7 is used as an active mechanism, which together constitute an active and high-rigidity box unfolding locking mechanism. Small network, simple and reliable structure.

[0119] In terms of specific engineering realization, an optional engineering structure of the upper box body unfolding locking mechanism 6 and the lower box body unfolding locking mechanism 7 is as follows: Figure 20-21 shown.

[0120] preferred, such as Figure 20 , The upper box unfolding locking mechanism 6 may specifically include: a first body 601 , a second body 602 , a locking lever 603 , a torsion spring 604 , a rotating shaft 605 , and a limit screw 606 . Wherein, one end of the locking rod 603 is installed between the two lugs of the first body 601 through the torsion spring 604 and the rotating shaft, and the ends of the two lugs of the first body 601...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com