Method and system for recovering pulp fibers from used absorbent articles

A technology for recycling pulp and absorbent, which is applied in the field of pulp fiber recycling of absorbent articles, which can solve the problems of heavy burden and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0072] The first embodiment will be described.

[0073] First, structural examples of absorbent articles will be described. An absorbent article includes a top sheet, a back sheet, and an absorber arranged between the top sheet and the back sheet. As an example of the size of an absorbent article, it is about 15 cm - 100 cm in length, and 5 cm - 100 cm in width. It should be noted that the absorbent article may also include further other components that are usually included in absorbent articles, such as a diffusion sheet, a leak-proof wall, and the like.

[0074] As a structural member of a surface sheet, a liquid-permeable nonwoven fabric, a synthetic resin film which has a liquid-permeable hole, these composite sheets, etc. are mentioned, for example. As a structural member of a back sheet, a liquid-impermeable nonwoven fabric, a liquid-impermeable synthetic resin film, and these composite sheets are mentioned, for example. As a structural member of a diffusion sheet, a ...

no. 2 Embodiment approach

[0155] The second embodiment will be described. Hereinafter, differences from the first embodiment will be mainly described. However, also in this embodiment, the case where an acidic aqueous solution is used as the inactivating aqueous solution will be described as an example.

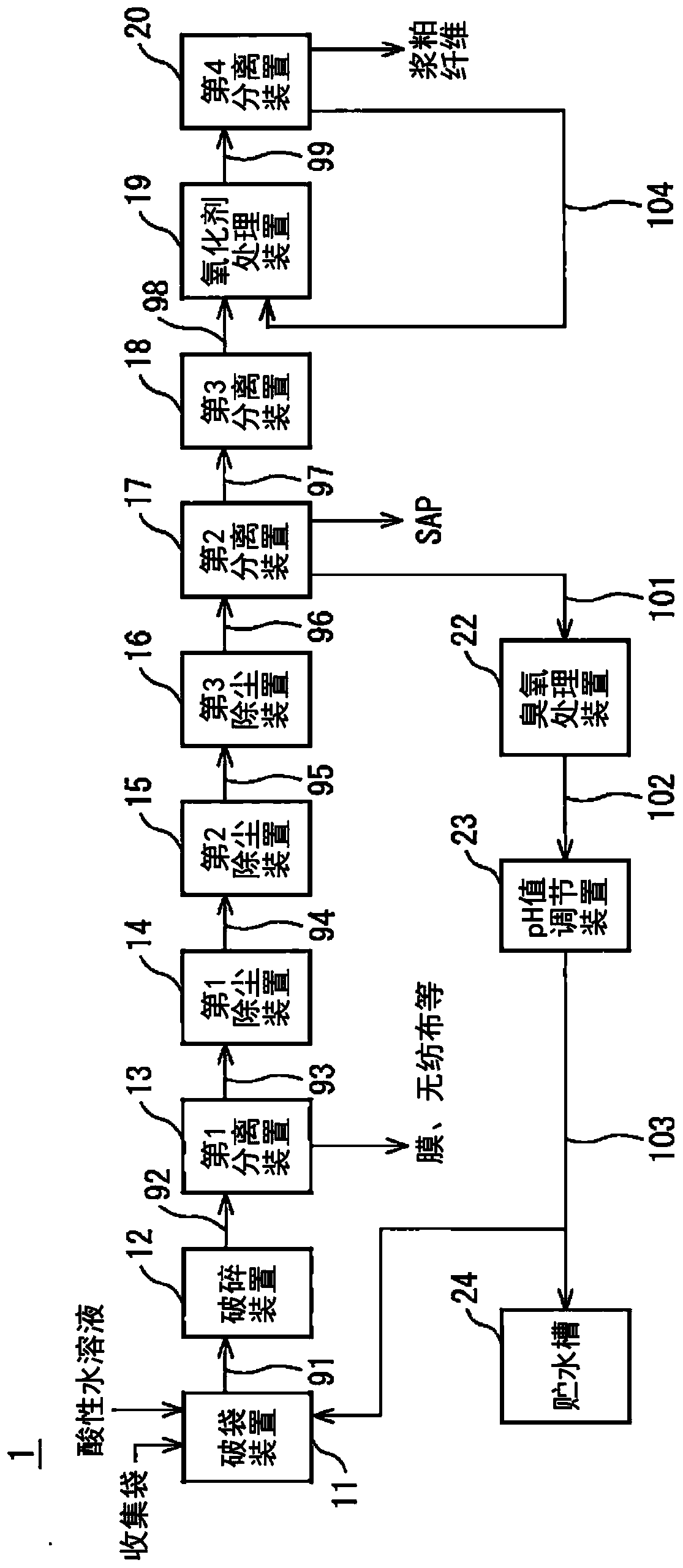

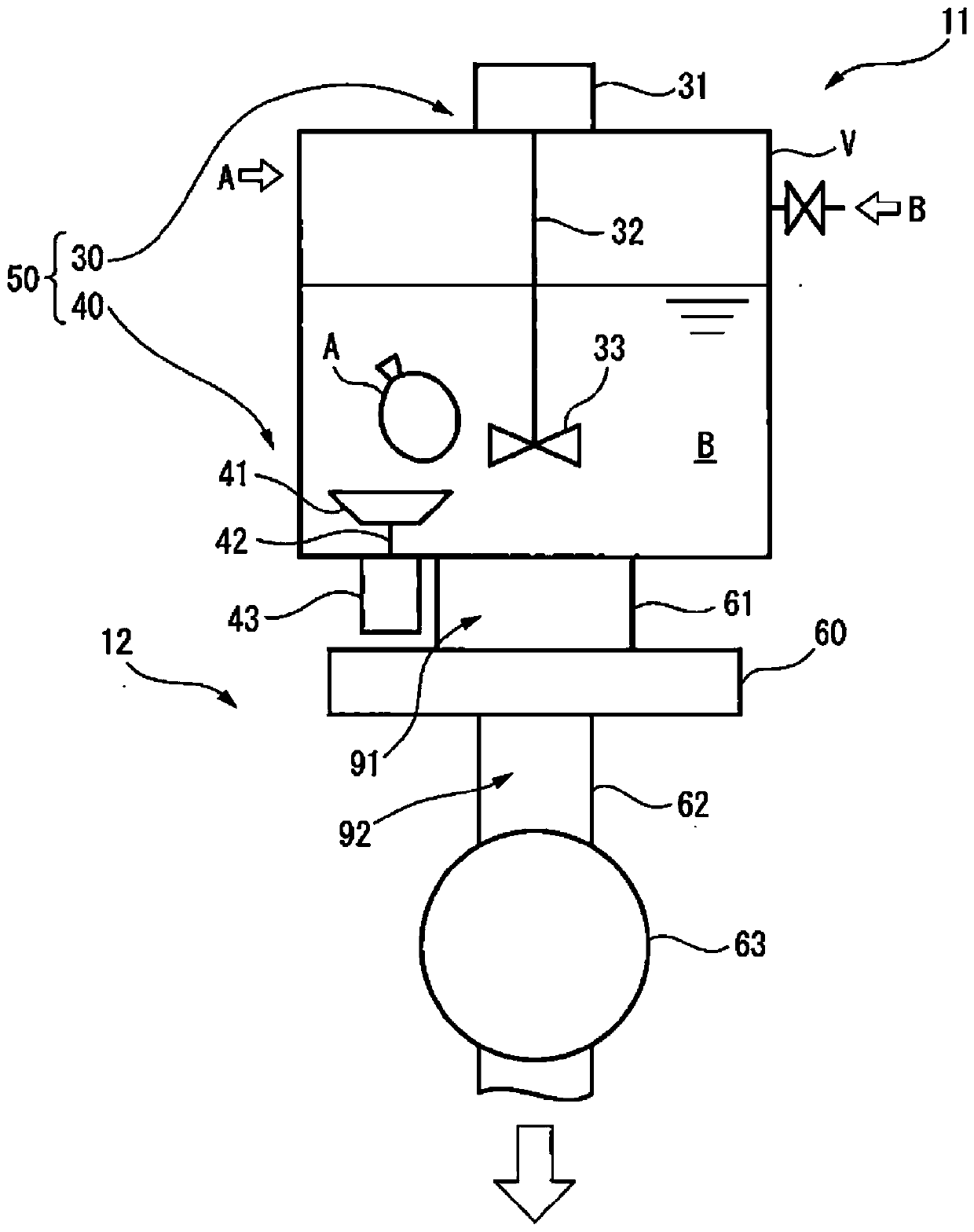

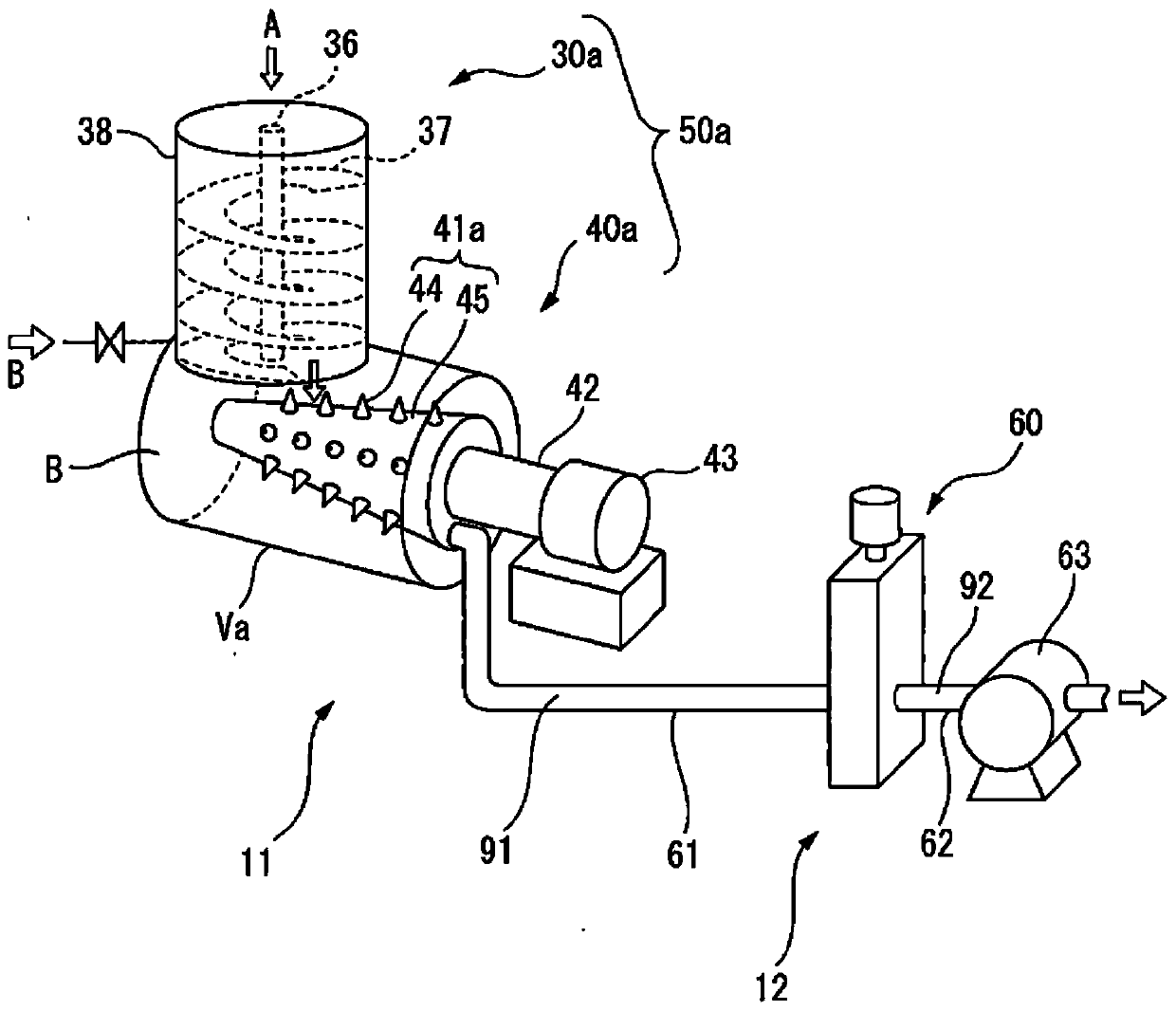

[0156] The system 1 used for the method of recovering pulp fibers from used absorbent articles will be described. Figure 6 It is a block diagram showing an example of the system 1 of this embodiment. The system 1 of the present embodiment includes a container (not shown), a crushing device 12, and a first separation device 13, and preferably includes a first dust removal device 14, a second dust removal device 15, a third dust removal device 16, a second separation device 17, The third separation device 18 , the oxidant treatment device 19 and the fourth separation device 20 . Hereinafter, it demonstrates in detail.

[0157] In this embodiment, the container (not shown), the crushing device 12 , ...

Embodiment

[0169] An example of the method for recovering pulp fibers from the above-mentioned used absorbent article will be described below.

[0170]In this example, the perforation step S11, the crushing step S12, and the first separation step S13 of the method of the above-mentioned first embodiment were carried out on the absorbent article, and the relationship between the crushing method and the amount of other materials (foreign substances) mixed was investigated. . Specifically, as the absorbent article, a disposable diaper for adults (unused) was used. In crushing process S12, the disposable diapers at the time of adjusting the crushing apparatus 12 so that the average value of the size of crushed objects may be 25 mm, 50 mm, and 100 mm were made into Examples 1-3. On the other hand, the disposable diaper which did not perform crushing process S12 was made into the comparative example.

[0171] exist Figure 9 shows the result of investigating the relationship between the cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com