Freeze-dried apple powder with low hygroscopicity and preparation method of freeze-dried apple powder

A low hygroscopicity, apple powder technology, applied in the field of food processing, can solve the problems of non-hygroscopic apple powder, low hygroscopicity, etc., and achieve the effects of easy operation, simple production equipment and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

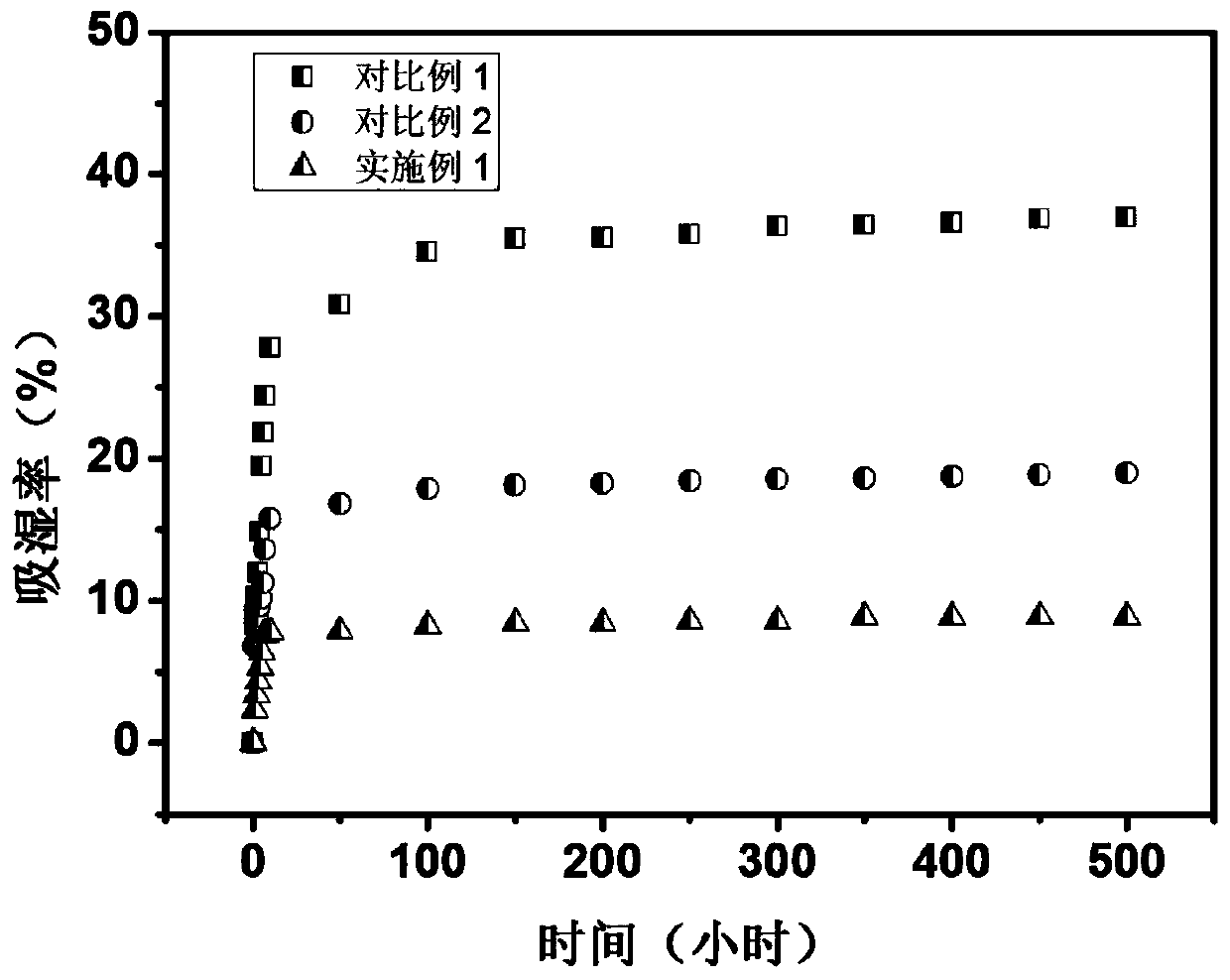

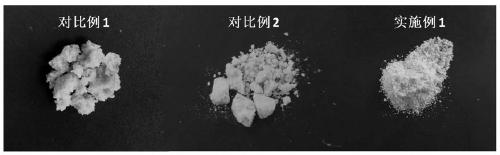

Examples

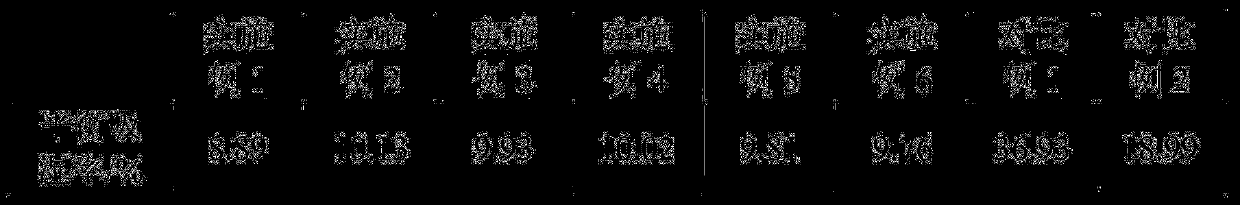

Embodiment 1

[0031] A preparation method with low hygroscopicity freeze-dried apple powder, comprising the following steps:

[0032] 1) Select ripe apples to be peeled, cored, and mechanically crushed to obtain apple pulp;

[0033] 2) Under the condition of mechanical stirring, add auxiliary materials to 65 parts of apple pulp, the auxiliary materials include the following raw materials in parts by weight: 8.5 parts of distilled water, 21.2 parts of gluten powder, and 5.3 parts of β-glucan;

[0034] The conditions of the mechanical stirring are: rotating speed 600r / min, time 30min;

[0035] 3) Adjust the pH of the mixed apple pulp obtained in step 2) to 9, and then stir again under the condition of 600r / min mechanical stirring for 30min. After the stirring is completed, pre-freeze at -20°C for 24h, and then place it in a cold trap at a temperature lower than -40°C , freeze-dried in a vacuum freeze-drying device with a vacuum degree of less than 5Pa in a vacuum box for 48 hours, and then m...

Embodiment 2

[0037] 1) with the 1) of embodiment 1;

[0038] 2) Under the condition of mechanical stirring, add auxiliary materials to 75 parts of apple pulp, the auxiliary materials include the following raw materials in parts by weight: 4.5 parts of distilled water, 16.4 parts of gluten powder, 4.1 parts of β-glucan;

[0039] The conditions of the mechanical stirring are: rotating speed 600r / min, time 30min;

[0040] 3) 3) with embodiment 1.

Embodiment 3

[0042] 1) with the 1) of embodiment 1;

[0043] 2) Under the condition of mechanical stirring, add auxiliary materials to 65 parts of apple pulp, the auxiliary materials include the following raw materials in parts by weight: 8.5 parts of distilled water, 21.2 parts of gluten powder, 5.3 parts of hydroxypropyl methylcellulose;

[0044] The conditions of the mechanical stirring are: rotating speed 600r / min, time 30min;

[0045] 3) 3) with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com