Special-shaped bag compression filling machine

A filling machine and special-shaped bag technology, which is applied in the field of special-shaped bag pressure filling machines, can solve the problems of bag mouth end loss, expansion of the outer support of the bundle mouth end of special-shaped bags, affecting the sealing performance, etc., to ensure the installation efficiency. , The effect of changing the pressurized flow and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

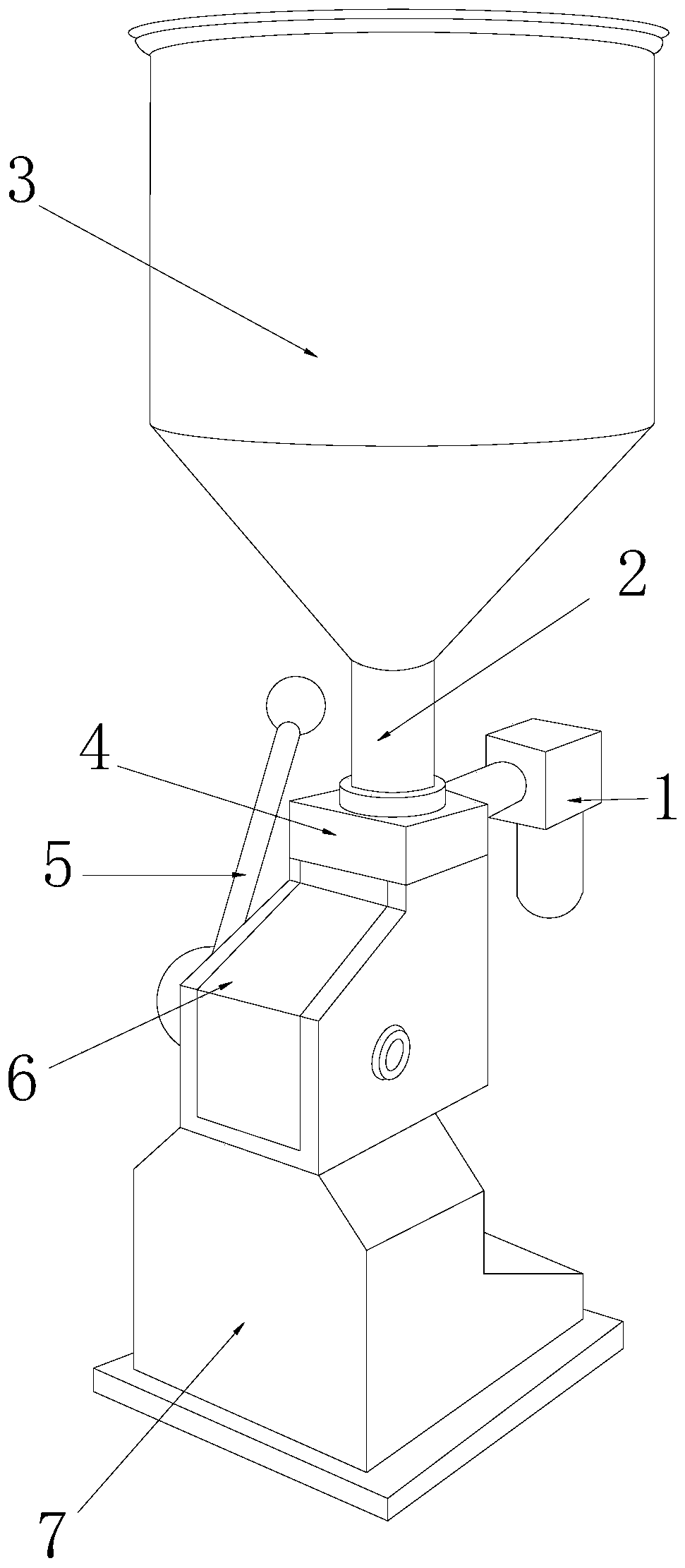

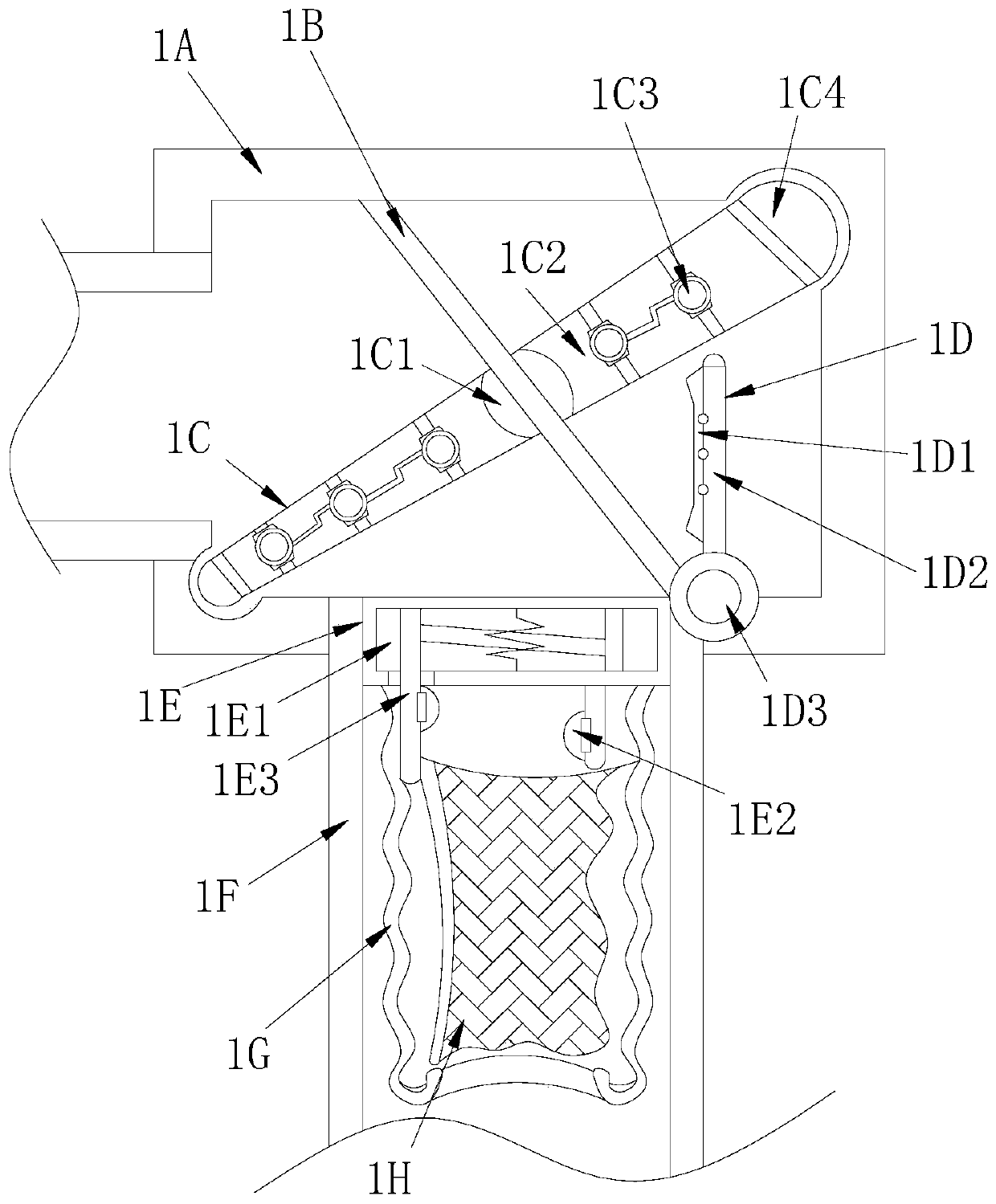

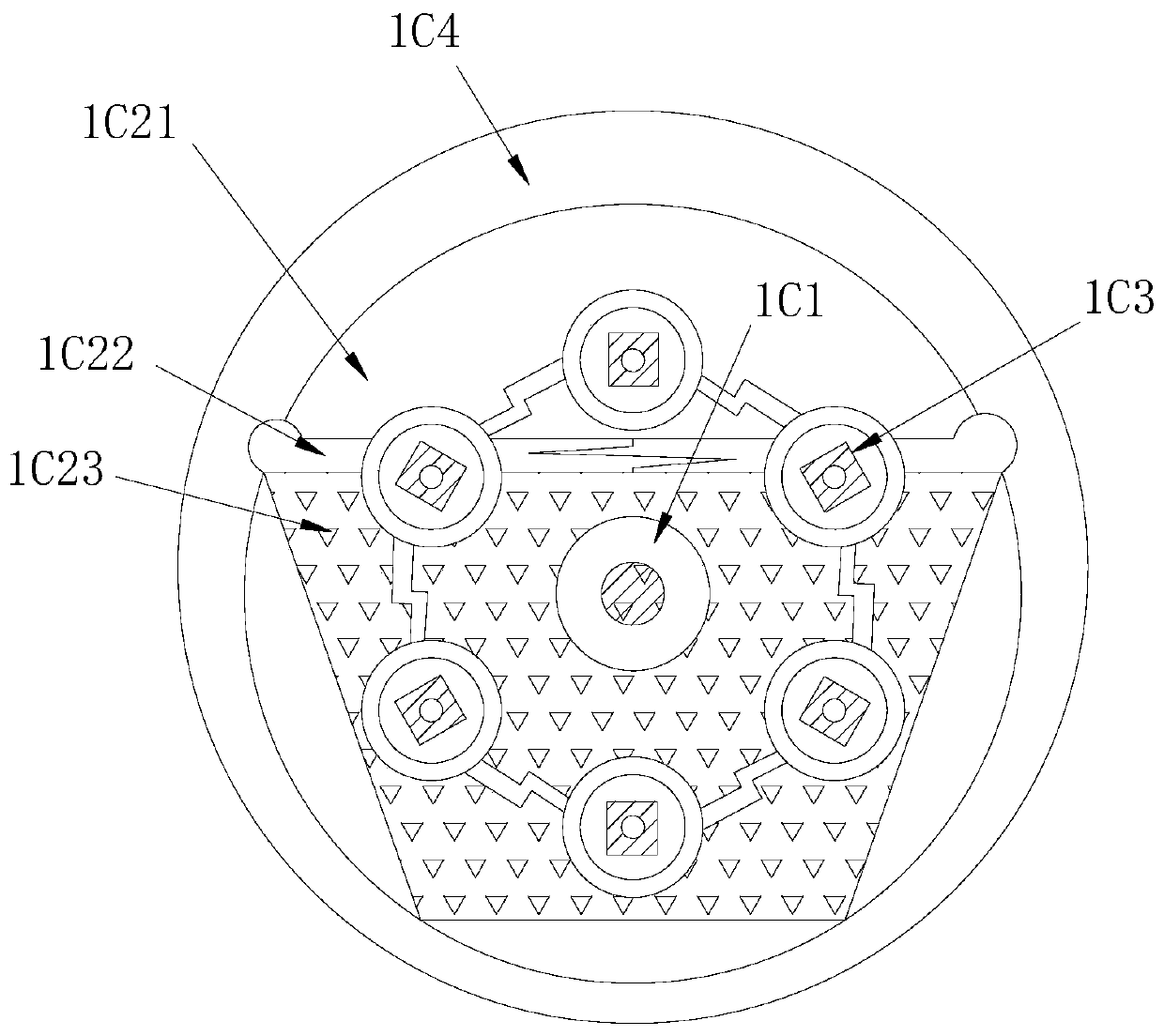

[0032] see Figure 1-Figure 6, the present invention provides a pressurized filling machine for special-shaped bags, the structure of which includes: valve disc filling pipe seat 1, through pipe 2, feeding chute 3, capstan receiving seat 4, ball shaft pressing rod 5, gear seat block 6. The base block 7, the valve disc filling pipe seat 1 is installed on the right side of the winch receiving seat 4 and is perpendicular to each other, the through-pipeline 2 is inserted and embedded under the bottom of the feeding chute 3 and the axes are in common line, the through pipe 2 is inserted on the top of the winch receiving seat 4 and penetrates each other, the ball axis pressing rod 5 is mechanically connected with the gear seat block 6, and the gear seat block 6 is nested in the base block 7 On the top, the capstan receiving seat 4 is close to the top surface of the gear seat block 6, the ball axis pressing rod 5 is installed on the rear side of the gear seat block 6 and is on the sa...

Embodiment 2

[0039] see Figure 1-Figure 6 , the present invention provides a special-shaped bag pressurized filling machine, other aspects are the same as embodiment 1, the difference is:

[0040] see figure 2 , the material blocking turning plate 1D is composed of turning channel plate 1D1, vertical plate 1D2, and traction wheel 1D3, and the turning channel plate 1D1 and vertical plate 1D2 are closely attached together and are on the same vertical plane, so The vertical plate 1D2 is inserted and embedded on the top of the traction wheel 1D3, and the vertical plate 1D2 swings along the traction wheel 1D3, so as to ensure the effect of resetting the lower row of splashing fluid bearing.

[0041] see Figure 4 , the frame turning channel 1D1 is composed of a frame tapered strip 1D11, an arc plate turning bar 1D12, a thin channel plate 1D13, and a wingspan 1D14. The upper and lower sides of the arc plate turning bar 1D12 are flexibly connected with the thin slot plate 1D13 and are on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com