Argon tail gas recycling and purifying method and system

A tail gas recovery and purification system technology, applied in chemical instruments and methods, specific gas purification/separation, inert gas compounds, etc., can solve the problems of high argon price, achieve low cost and energy consumption, increase argon production, and solve market supply and demand problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

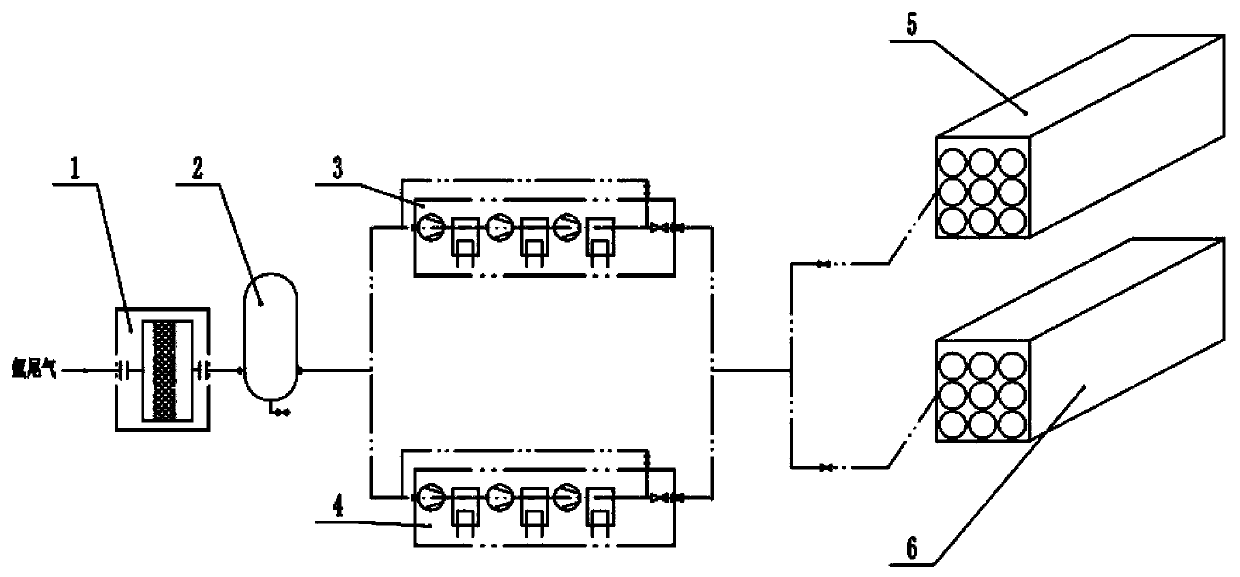

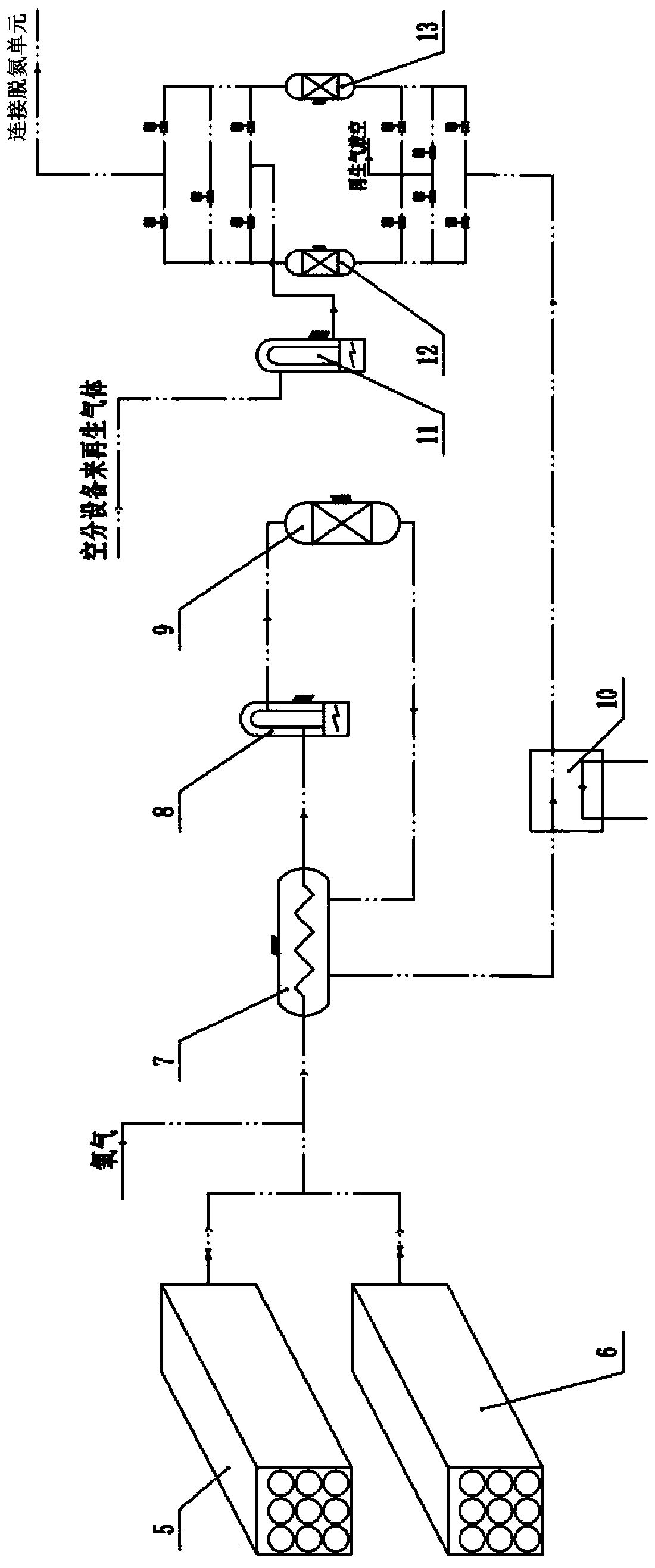

[0035] Embodiment 1: a method for recovering and purifying argon tail gas for recovering and purifying argon tail gas containing oxygen, nitrogen, carbon monoxide and hydrocarbons, comprising the following steps:

[0036] Step 1: Collect the argon tail gas from the argon gas use end, remove the solid particles in the argon tail gas to obtain the pre-filtered argon tail gas, pressurize the pre-filtered argon tail gas to the rated pressure to obtain the pressurized argon tail gas;

[0037] Step 2: catalyzing the oxygen, carbon monoxide, and hydrocarbons in the pressurized argon tail gas to obtain the catalyzed argon tail gas;

[0038] Step 3: Adsorbing carbon dioxide and water in the catalyzed argon tail gas to obtain the adsorbed argon tail gas;

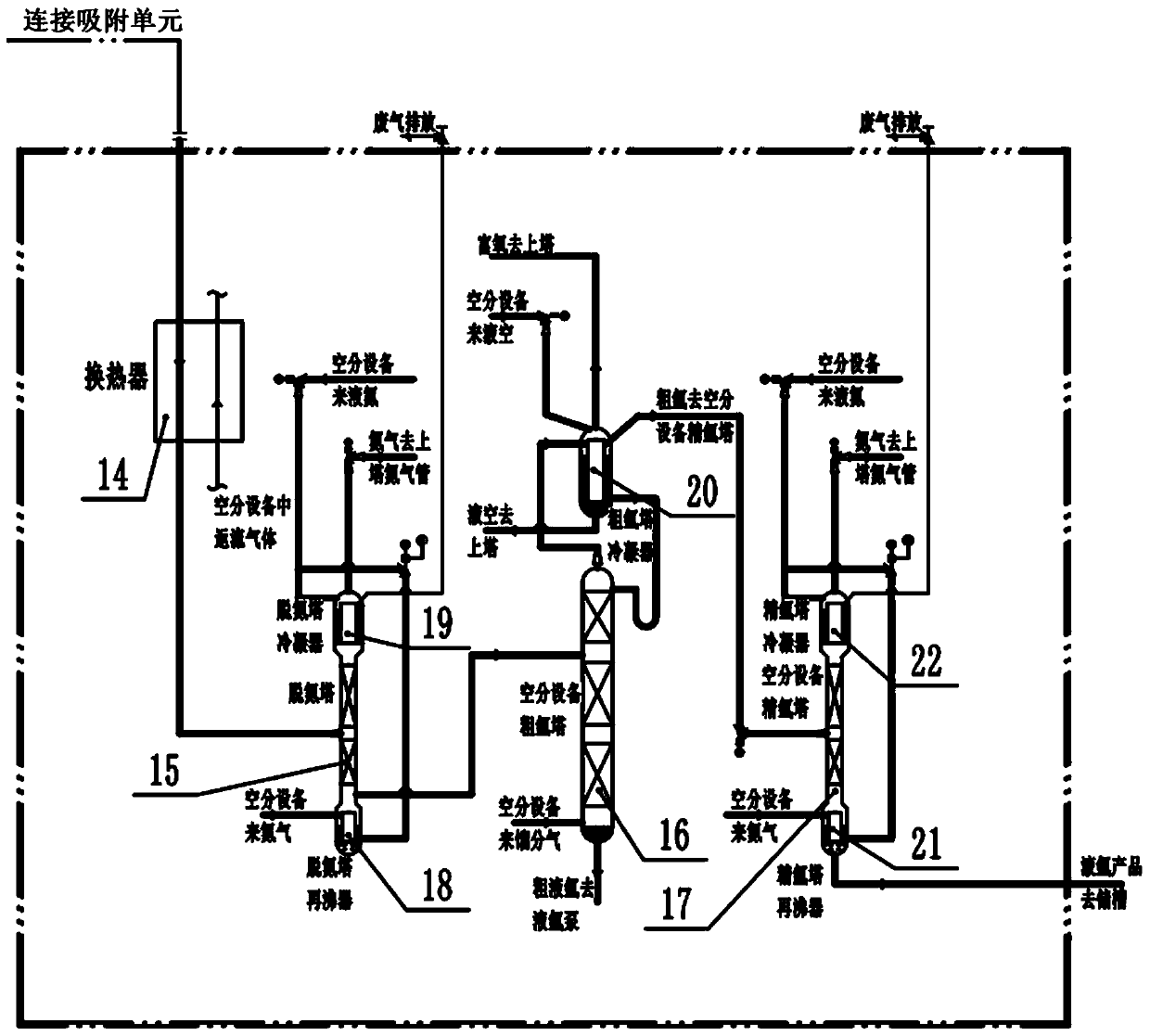

[0039] Step 4: removing part of the nitrogen in the adsorbed argon tail gas to obtain the denitrified argon tail gas;

[0040] Step 5: rectifying the argon tail gas after denitrification to obtain high-purity argon.

[0041] In step...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap