A preparation method of selenium-doped silicon-calcium-phosphorus bioactive mesoporous glass powder

A mesoporous glass, bioactive technology, applied in tissue regeneration, prosthesis, medical science, etc., can solve the problems of low specific surface area of MBG, unfavorable bone tissue integration and angiogenesis, and achieve convenient and effective operation, simple method, The effect of simple preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

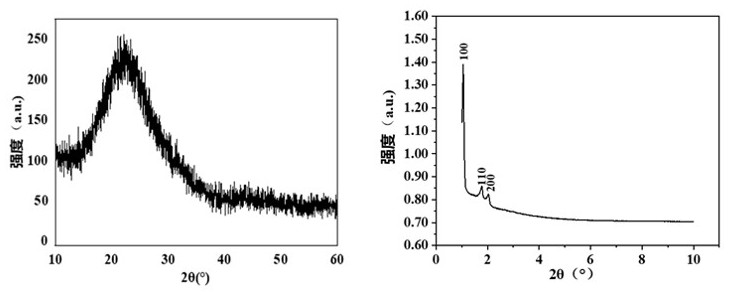

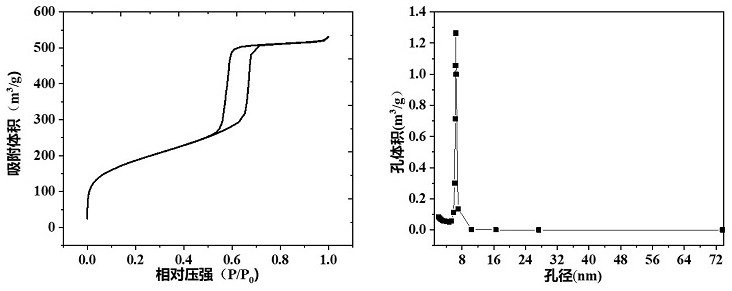

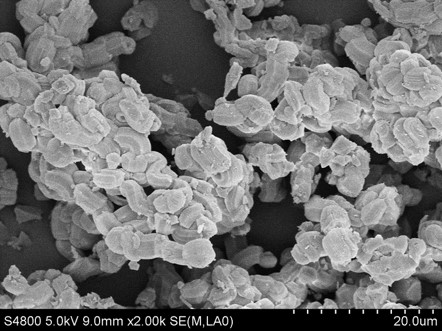

[0021] Example 1: Use an analytical balance to weigh 1 g of analytically pure P123 and disperse it in 2 mol / L concentrated hydrochloric acid with a volume of 50 ml, and stir in a 37°C water bath for 30 min until the solution is clear and colorless. Measure 0.308ml TEP and slowly add it dropwise to the above liquid, keep stirring for 30min, weigh 1.98g Ca(NO 3 ) 2 .4H 2 O was added to the above liquid, and when Ca(NO 3 ) 2 .4H 2 O is completely dissolved, add 0.028g SeO 2 , then slowly add 3.05ml TEOS dropwise, and after all the addition is completed, keep stirring in a water bath at 37°C for 12h. Then the above liquid was transferred to a 100ml polytetrafluoroethylene reactor and subjected to hydrothermal reaction at 100°C for 24h. After cooling to room temperature, discard the supernatant, add absolute ethanol and stir properly, after standing still, discard the supernatant, transfer the powder to a porcelain boat and dry in an electric blast drying oven at 60°C. The c...

Embodiment 2

[0022] Example 2: Use an analytical balance to weigh 1 g of analytically pure P123 and disperse it in 2 mol / L concentrated hydrochloric acid with a volume of 50 ml, and stir in a 37°C water bath for 30 min until the solution is clear and colorless. Measure 0.308ml TEP and slowly add it dropwise to the above liquid, keep stirring for 30min, weigh 1.98g Ca(NO 3 ) 2 .4H 2 O was added to the above liquid, and when Ca(NO 3 ) 2 .4H 2 O is completely dissolved, add 0.056g SeO 2 , then slowly add TEOS dropwise, and after all the addition is completed, keep stirring in a water bath at 37°C for 12h. Then the above liquid was transferred to a 100ml polytetrafluoroethylene reactor and subjected to hydrothermal reaction at 100°C for 24h. After cooling to room temperature, discard the supernatant, add absolute ethanol and stir properly, after standing still, discard the supernatant, transfer the powder to a porcelain boat and dry in an electric blast drying oven at 60°C. The complete...

Embodiment 3

[0023] Example 3: Use an analytical balance to weigh 1 g of analytically pure P123 and disperse it in 2 mol / L concentrated hydrochloric acid with a volume of 50 ml, and stir in a 37°C water bath for 30 min until the solution is clear and colorless. Measure 0.308ml TEP and slowly add it dropwise to the above liquid, keep stirring for 30min, weigh 1.98g Ca(NO 3 ) 2 .4H 2 O was added to the above liquid, and when Ca(NO 3 ) 2 .4H 2 O was completely dissolved, adding 0.112g SeO 2 , then slowly add TEOS dropwise, and after all the addition is completed, keep stirring in a water bath at 37°C for 12h. Then the above liquid was transferred to a 100ml polytetrafluoroethylene reactor and subjected to hydrothermal reaction at 100°C for 24h. After cooling to room temperature, discard the supernatant, add absolute ethanol and stir properly, after standing still, discard the supernatant, transfer the powder to a porcelain boat and dry in an electric blast drying oven at 60°C. The comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com