Preparation method of hydrogen storage material

A technology of hydrogen storage materials and sol-gel method, which is applied in the field of preparation of hydrogen storage materials, achieves the effects of strong controllability, lower hydrogen desorption temperature, and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

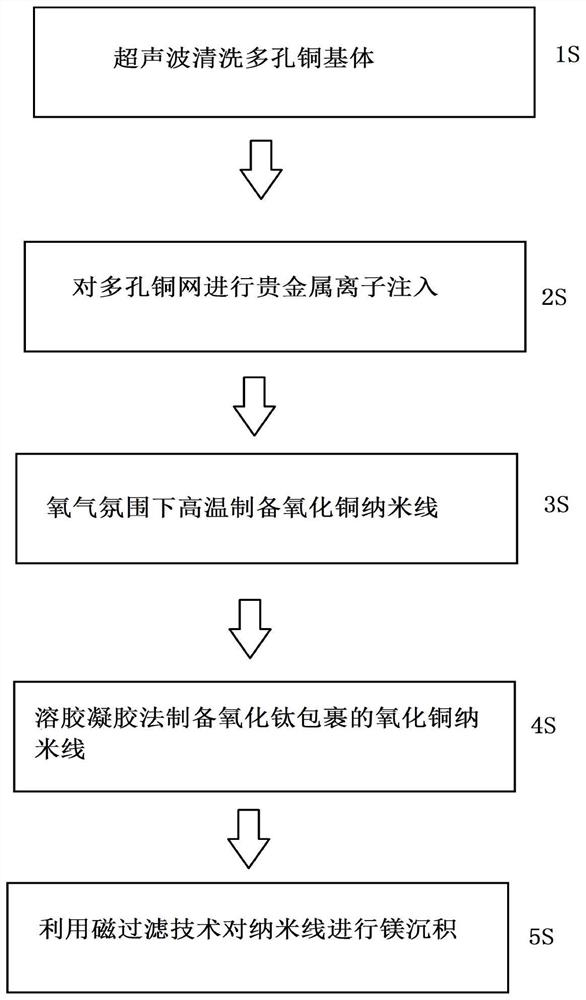

[0045] A kind of preparation method of hydrogen storage material of the present invention, comprises the following steps:

[0046] 1S: Ultrasonic cleaning of the porous copper mesh;

[0047] The thickness of the porous copper mesh is 0-2mm, and the mesh number of the copper mesh is 600-1200 mesh

[0048] 2S: Implantation of noble metal ions into the porous copper mesh;

[0049] The metal ion source is selected for implantation, the ion beam current is 0.2-1mA, the pulse width is 20-200μs, the implanted metal is Ag, Au, Pt, etc., the implantation energy is 0-4KeV, and the dose is 1×10 15 -1×10 16 / cm 2 ;

[0050] 3S: Preparation of copper oxide nanowires at high temperature under oxygen atmosphere;

[0051] The temperature for high temperature oxidation in vacuum equipment is 400-750°C, the gas in the vacuum chamber is oxygen gas, the pressure is 0.1-50Pa, the length of copper oxide nanowires is 30-100μm, and the density is 10-50 / μm 2 .

[0052] 4S: copper oxide nanowire...

Embodiment 1

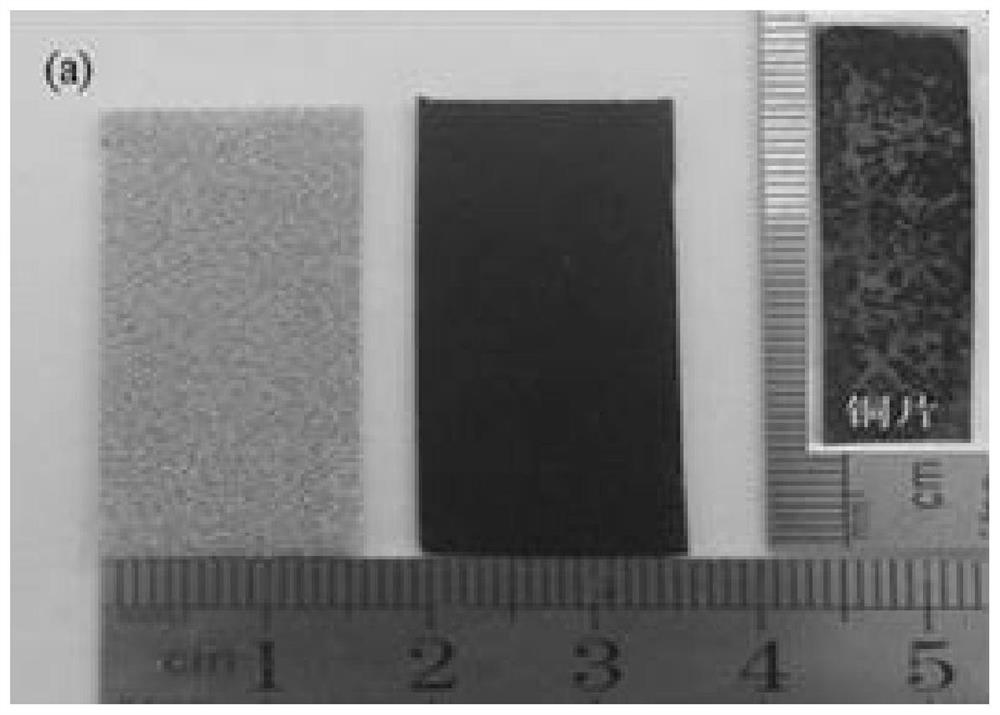

[0058] 1S: Ultrasonic cleaning of the porous copper mesh;

[0059] The thickness of the porous copper mesh is 0-2mm, and the mesh number of the copper mesh is 800 mesh

[0060] 2S: Implantation of noble metal ions into the porous copper mesh;

[0061] The metal ion source was selected for implantation, the ion beam current was 0.5mA, the pulse width was 50μs, the implanted metal was Ag, the implantation energy was 2KeV, and the dose was 1×10 15 -1×10 16 / cm 2 ;

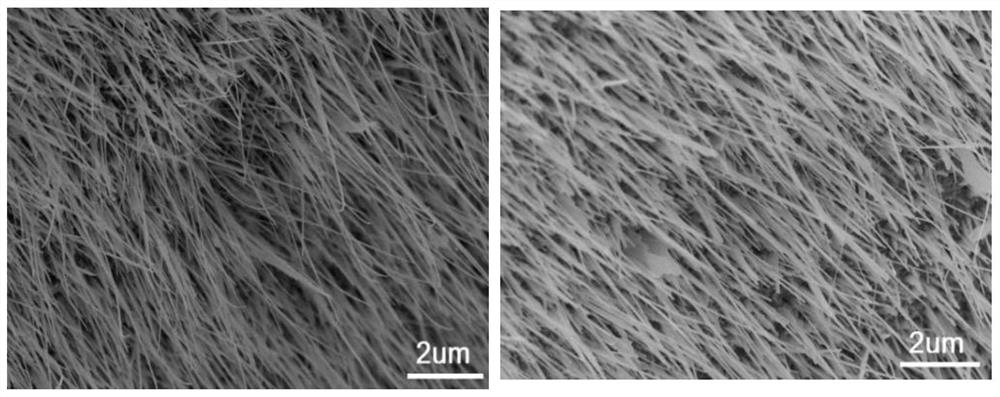

[0062] 3S: Preparation of copper oxide nanowires at high temperature under oxygen atmosphere;

[0063] When the vacuum equipment is oxidized at high temperature, the temperature is 650°C, the gas in the vacuum chamber is oxygen gas, and the pressure is 10Pa. The length of the prepared copper oxide nanowire is 30 μm, and the density is 30 / μm 2 .

[0064] 4S: copper oxide nanowires wrapped in titanium oxide by sol-gel method;

[0065] A wrapped titanium dioxide film is prepared by a sol-gel method, the solution i...

Embodiment 2

[0069] 1S: Ultrasonic cleaning of the porous copper mesh;

[0070] The thickness of the porous copper mesh is 0-2mm, and the mesh number of the copper mesh is 1000 mesh

[0071] 2S: Implantation of noble metal ions into the porous copper mesh;

[0072] The metal ion source was selected for implantation, the ion beam current was 0.6mA, the pulse width was 50μs, the implanted metal was Ag, the implantation energy was 3KeV, and the dose was 1×10 15 -1×10 16 / cm 2 ;

[0073] 3S: Preparation of copper oxide nanowires at high temperature under oxygen atmosphere;

[0074] The temperature of vacuum equipment is 700°C during high temperature oxidation, the gas in the vacuum chamber is oxygen gas, the pressure is 20Pa, the length of copper oxide nanowires is 40μm, and the density is 30 / μm 2 .

[0075] 4S: copper oxide nanowires wrapped in titanium oxide by sol-gel method;

[0076] A wrapped titanium dioxide film is prepared by a sol-gel method, the solution includes tetrabutyl ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com