A kind of solid-state fluorescent carbon dots based on nanoporous glass and preparation method thereof

A nanoporous, solid-state fluorescence technology, applied in the direction of nano-carbon, chemical instruments and methods, luminescent materials, etc., can solve the problems of limited preparation process, high preparation cost, and low carbon dot loading, and achieve high fluorescence intensity and method Simple, glow-steady effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

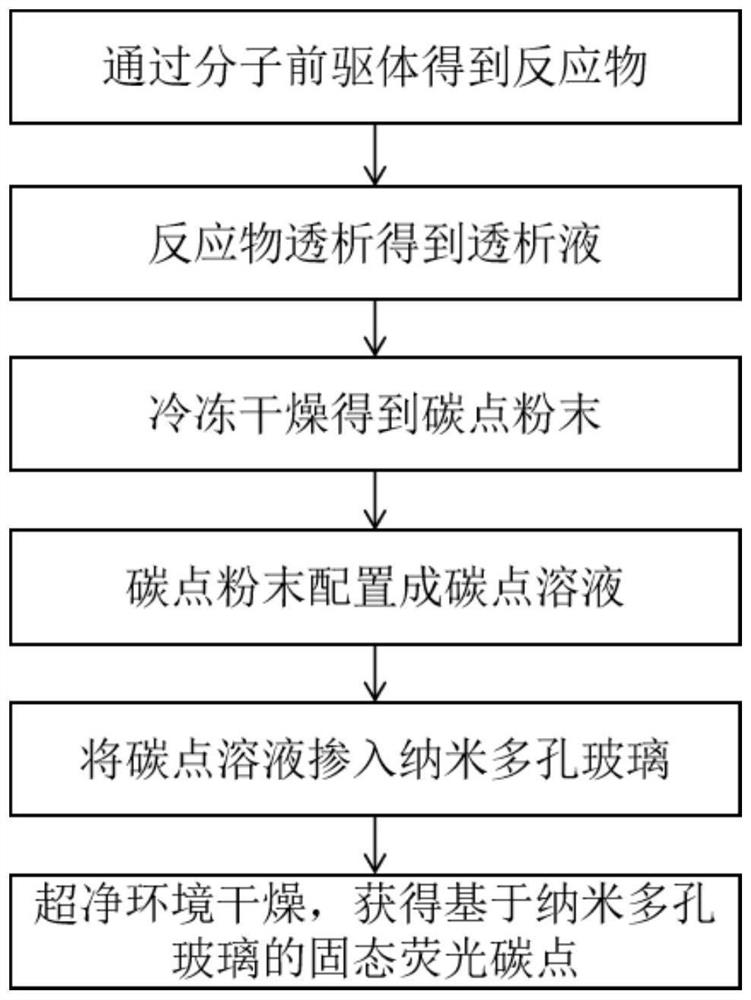

[0032] The embodiment of the present invention provides a method for preparing solid-state fluorescent carbon dots based on nanoporous glass, such as figure 1 shown, including the following steps:

[0033] S1, adopt a one-step high temperature method, stir a certain proportion of the carbon source molecular precursor evenly, then put it into the inner tank of the polytetrafluoroethylene hydrothermal kettle, and react at a reaction temperature of 160 ° C ~ 200 ° C for 6 ~ 12 hours to obtain Reactant;

[0034] Preferably, the carbon source molecular precursor is p-phenylenediamine and anhydrous aluminum chloride, and the molar ratio is 50:3 to 25:6, more preferably 50:3 or 35:3 or 25:6; or , the carbon source molecular precursor is citric acid and urea, and its mass ratio is 1:1 to 1:3, more preferably 1:2; or, the carbon source molecular precursor is citric acid and o-phenylenediamine , its mass ratio is 1:1 to 1:8, more preferably 1:6, so that it can fully react.

[0035] S...

Embodiment 1

[0046] Weigh 1 g of citric acid and 2 g of urea into a beaker, grind evenly, add 30 mL of deionized water, stir evenly, put it into the inner tank of a polytetrafluoroethylene reactor, put the reactor into an oven, and set the reaction temperature to 160 ℃, the reaction time is 6 hours; after the reaction is over, put it into a 3500D dialysis bag, and dialyze for 36 hours to further purify the reactant; collect the liquid in the dialysis bag, put it into a freeze dryer, and obtain a powder sample.

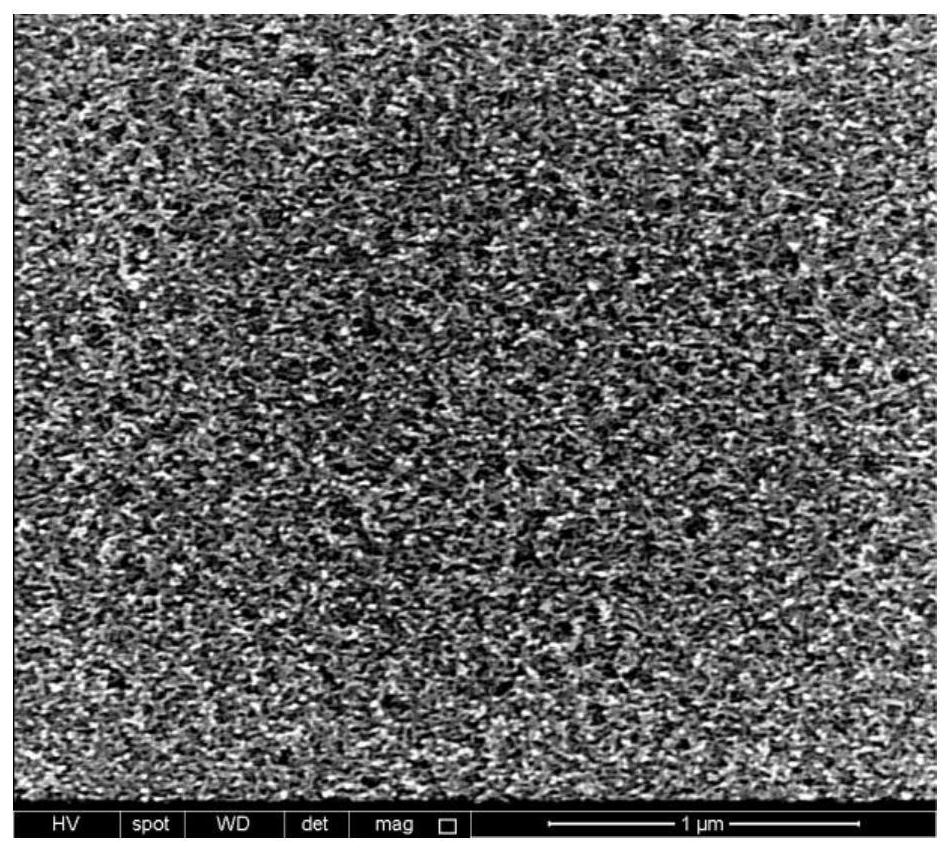

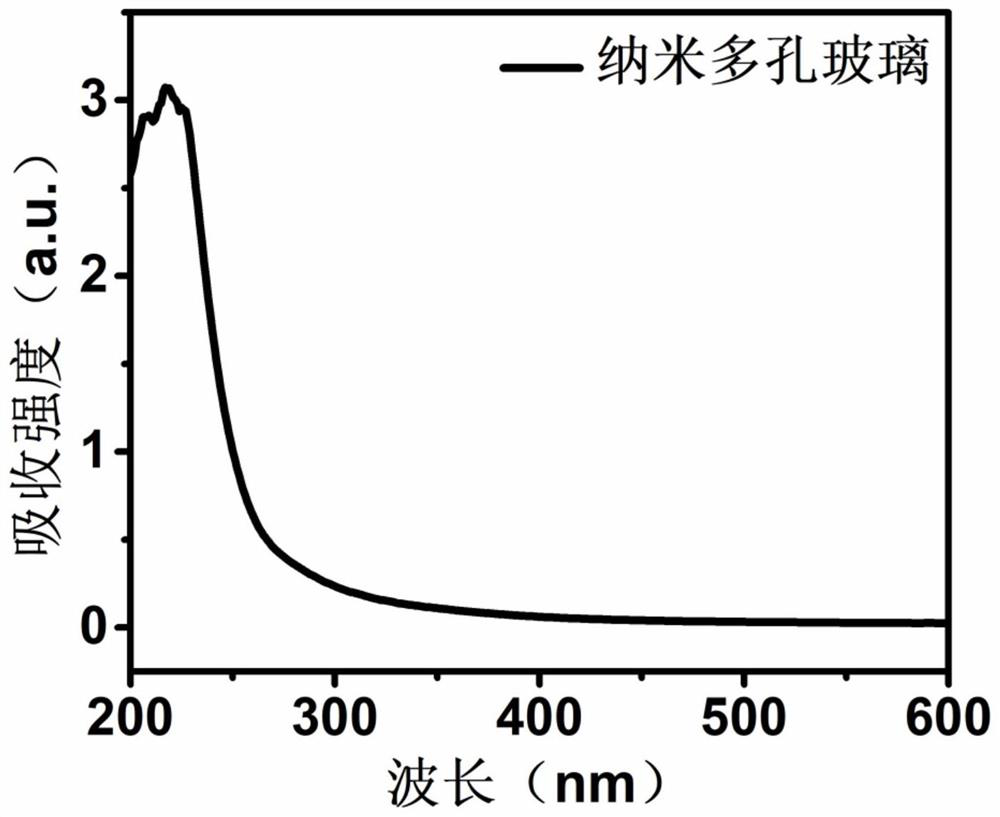

[0047] Dissolve 0.0078 g of powdered carbon dots in 10 ml of deionized water, and sonicate for 30 minutes to obtain a uniform carbon dot solution; take 1 piece of nanoporous glass sheet, and immerse the nanoporous glass sheet into the carbon dot solution by liquid phase method for 72 hours; then , and naturally dried for 1 day in a clean room environment to obtain solid carbon dots based on nanoporous glass sheets.

Embodiment 2

[0049] Weigh 0.2g of citric acid and 1.2g of o-phenylenediamine into a beaker, grind it evenly, put it into the inner tank of a polytetrafluoroethylene reaction kettle, put the reaction kettle into an oven, set the reaction temperature to 170 ° C, and the reaction time After the reaction is over, put it into a 3000D dialysis bag, and dialyze for 48 hours to further purify the reactant; collect the liquid in the dialysis bag, put it into a freeze dryer, and obtain a powder sample.

[0050] Dissolve 0.018g of powdered carbon dots in 20ml of deionized water, and sonicate for 30 minutes to obtain a uniform carbon dot solution; take 1 piece of nanoporous glass sheet, and immerse the nanoporous glass sheet into the carbon dot solution by liquid phase method for 72 hours; then , and naturally dried for 1 day in a clean room environment to obtain solid carbon dots based on nanoporous glass sheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com