Small-size vibration and noise reduction frog structure for rail transit

A rail transit, vibration reduction and noise reduction technology, applied in the direction of tracks, roads, switches, etc., can solve the problems of station design difficulties, increase investment, etc., reduce maintenance, improve safety, reduce vibration and noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

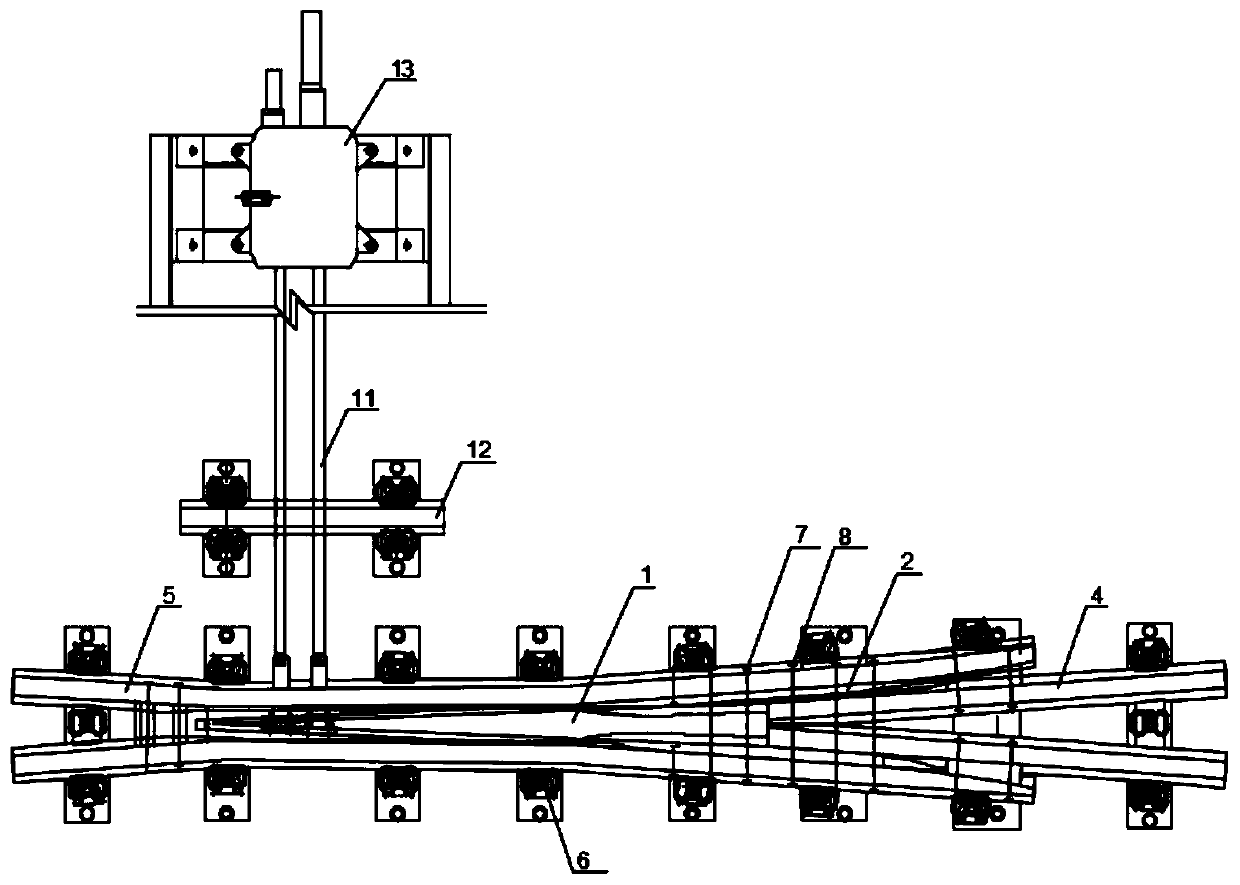

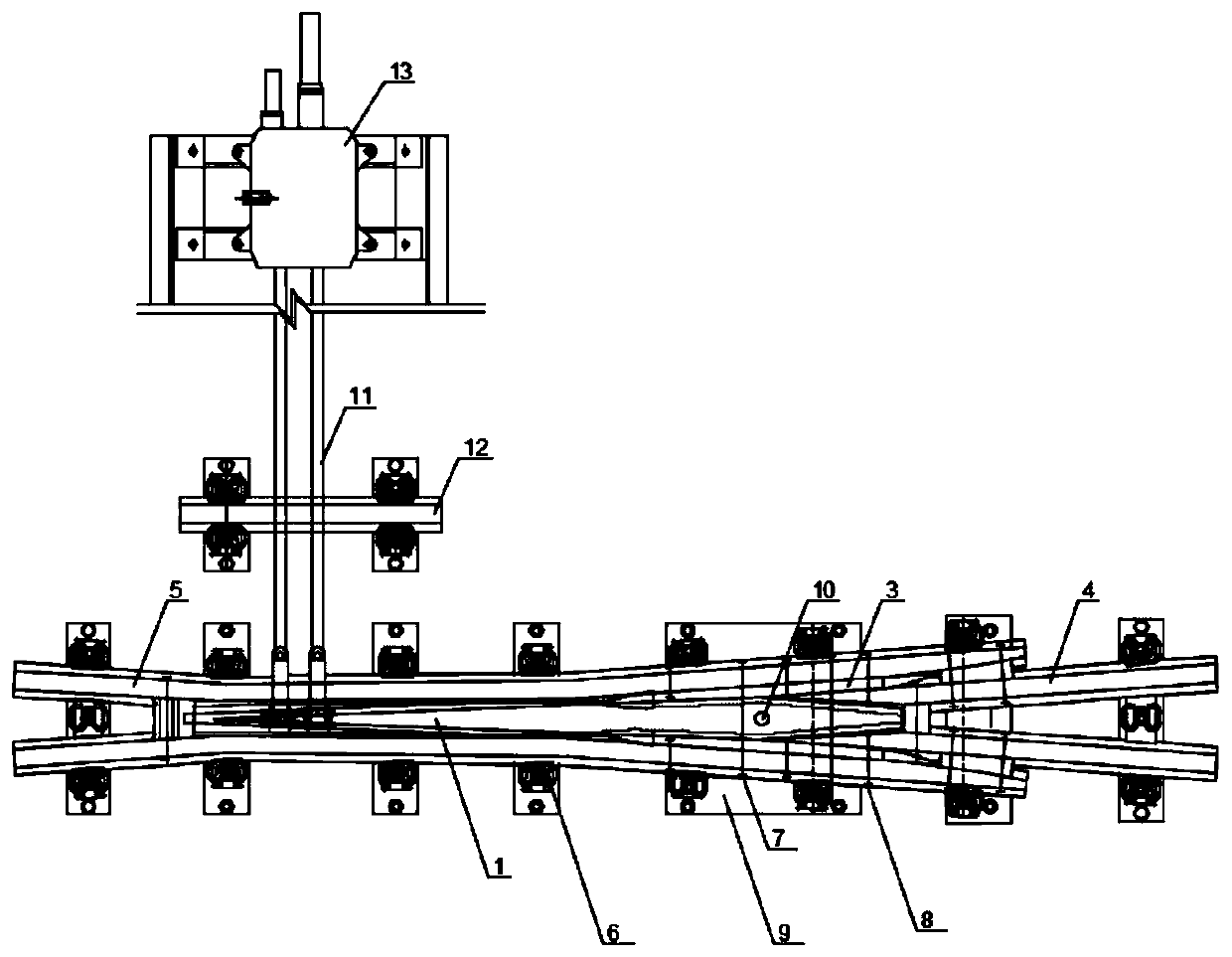

[0035] see figure 1 with 2 , respectively show two embodiments of the small-number vibration-damping and noise-reducing frog structure for rail transit of the present invention.

[0036] The small-number vibration-reducing and noise-reducing frog structure for rail transit can be an interval iron type live joint structure (see figure 1 ) or spaced iron double limb miter joint structure (see figure 2 ) two ways, which can mainly include core rail 1, wing rail 5, fork heel rail 4, spacer iron, conversion device 13 and other components.

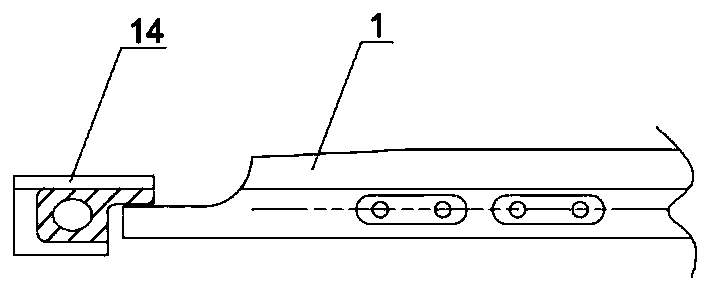

[0037] see figure 1 In the spacer iron type joint structure shown, the frog structure of the present invention mainly includes parts such as core rail 1, wing rail 5, fork heel rail 4, spacer iron 2, conversion device 13, and the heel end of the core rail 1 The front end of the fork and heel rail 4 adopts a spacer iron type joint structure, and the spacer iron 2 is divided into a front end and a rear end with the position of the rail gap wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com