Hot-water lithium bromide absorption-type water chilling unit driven by ultra-low-temperature waste heat

A technology of ultra-low temperature and lithium bromide, applied in the direction of adsorption machines, refrigerators, refrigeration components, etc., can solve the problems of high material cost and low coefficient of performance, and achieve a comprehensive economy of reducing heat transfer area, improving coefficient of performance, energy saving and emission reduction and the effect of social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

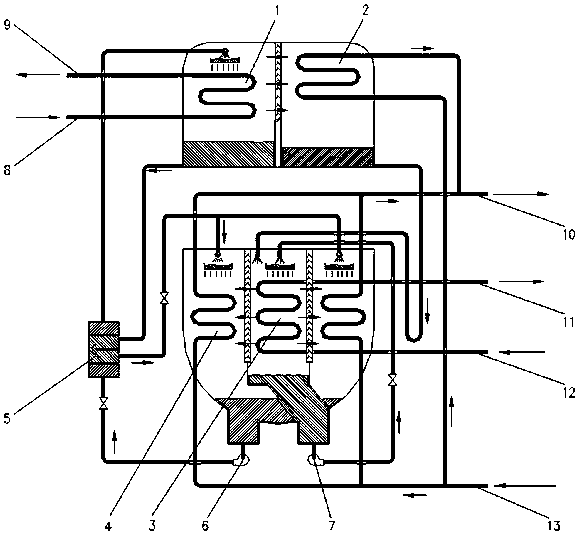

[0013] see figure 2 , the present invention relates to a hot water lithium bromide absorption chiller driven by ultra-low temperature waste heat, comprising a hot water generator 1, a condenser 2, an evaporator, an absorber, a heat exchanger 5, a generator pump 6 and a refrigerant pump 7, The ultra-low temperature residual hot water enters and exits the hot water generator 1 through the hot water inlet pipe 8 and the hot water outlet pipe 9, the cooling water enters and exits the unit through the cooling water inlet pipe 13 and the cooling water outlet pipe 10, and the cold water passes through the cold water inlet pipe 12 and the cold water outlet pipe 11 into and out of the unit, the evaporator is divided into a high-temperature section evaporator 19 and a low-temperature section evaporator 16, the absorber is divided into a high-temperature section absorber 20 and a low-temperature section absorber 15, and the concentrated solution of the hot water generator 1 The heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com