Rock porosity and permeability combined test device and test method under triaxial condition

A technology for rock porosity and joint testing, which is used in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

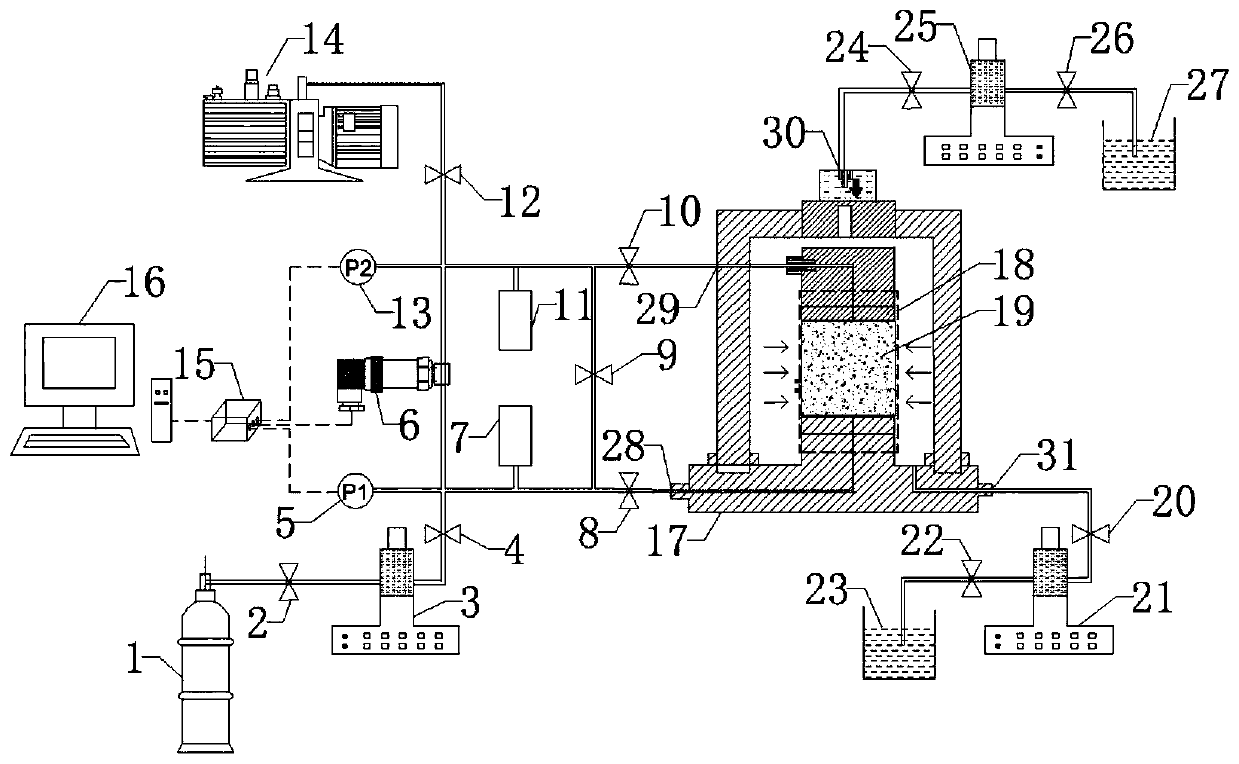

[0095] This embodiment provides a joint testing device for rock porosity and permeability under triaxial conditions, such as figure 1 As shown, the device includes: porosity and permeability measurement components, core holders, confining pressure loading components, axial pressure loading components, multi-channel data acquisition cards and data storage and processing modules; wherein the porosity and permeability measurement components, confining pressure loading components and axial pressure The loading assembly is connected to the core holder. The data acquisition card is used to collect the data of the first pressure sensor 5, the second pressure sensor 13 and the differential pressure gauge 6 in the porosity test pipeline, and transmit them to the data storage and processing module.

[0096] The porosity measurement assembly includes a high-pressure gas cylinder 1, a first valve 2, a pore pressure booster pump 3, a second valve 4, a first pressure sensor 5, a differentia...

Embodiment 2

[0105] In this embodiment, the joint test of rock porosity and permeability under triaxial conditions is carried out based on the above-mentioned device. The specific method includes the following steps:

[0106] Step 1: Put a standard cylindrical stainless steel sample 19 with a diameter of 25mm and a length of 50mm into the core holder 17, and seal it with a heat shrinkable tube 18 to isolate the confining pressure and pore pressure;

[0107] Step 2: Apply a certain confining pressure and axial pressure to the stainless steel sample through the confining pressure loading assembly and the axial pressure loading assembly, and then close it, so that the confining pressure and axial pressure are maintained at the design value, and ensure that the pore pressure is formed on the surface of the sample during the measurement process. surface flow;

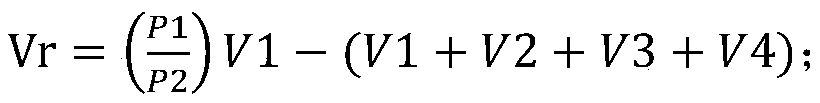

[0108] Step 3: Vacuumize the porosity and permeability measurement components. Close the second valve 4, keep the third valve 8, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com