Radiator with built-in integrated supporting structure and preparation method of radiator

A technology for supporting structures and radiators, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of poor flatness, manual placement of copper columns, and high labor costs, saving processes and improving cooling effects. , good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

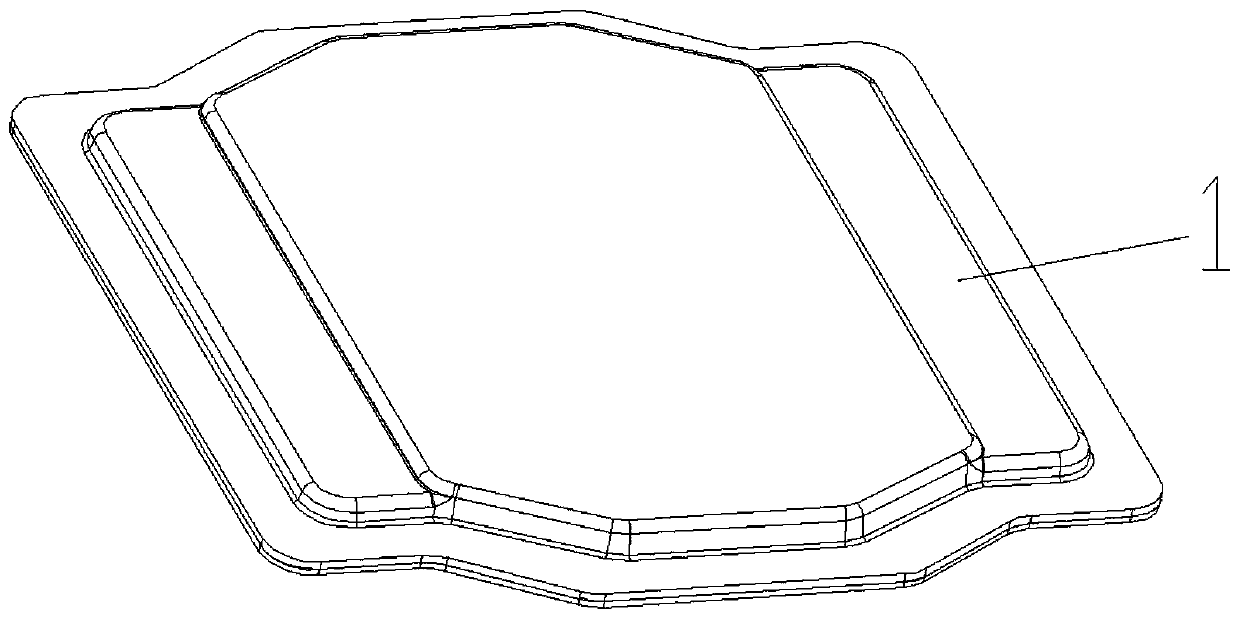

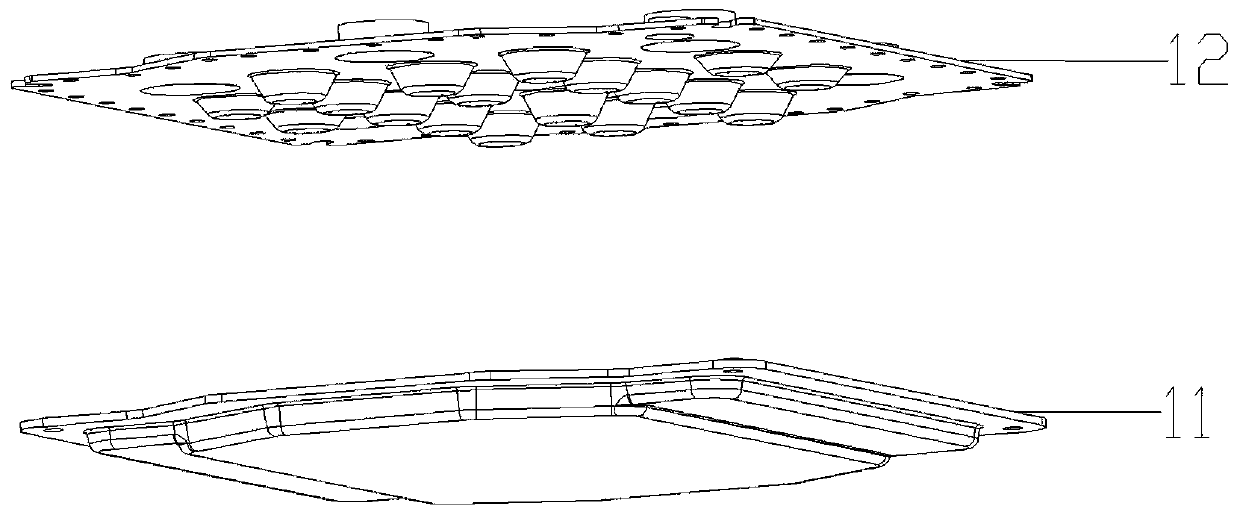

[0041] see Figure 1-10 As shown, a heat sink with a built-in integrated support structure includes a heat dissipation substrate 1. The heat dissipation substrate 1 is a VC structure. The heat dissipation substrate 1 includes a base and an upper plate. Edge sealing is carried out by means of material welding. The base 11 is provided with a cavity, and a supporting joint is arranged in the cavity. A circle of welding surface 112 is arranged outside the cavity, and a circle of solder is placed on the welding surface 112. The upper plate 12 is covered on the welding surface and closes the opening, and the base 11 and the upper plate 12 are assembled together for solder welding. When the base 11 and the upper plate 12 are heated to a temperature slightly higher than the melting point of the solder, The solder melts and is sucked and filled between the welding surface and the upper plate by capillary action, and the liquid solder diffuses and dissolves with the welding surface and ...

Embodiment 2

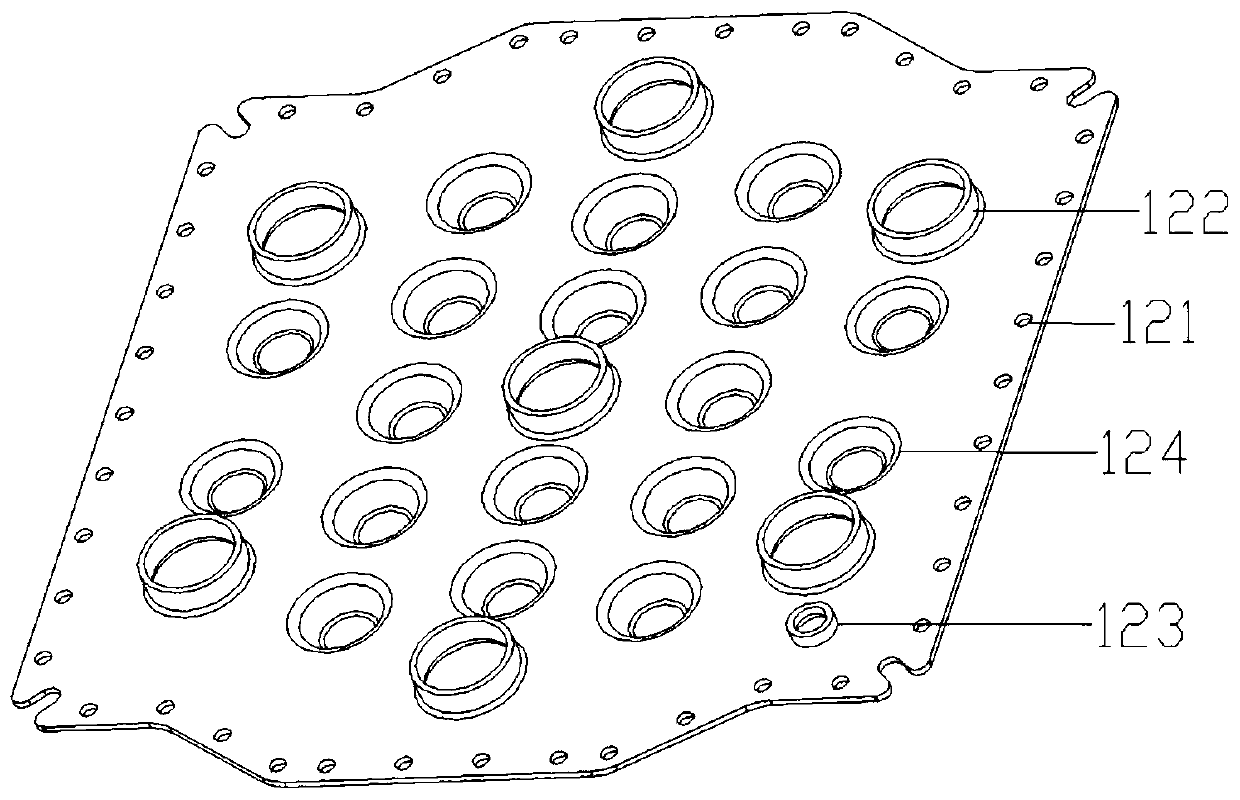

[0046] This embodiment is a modification of Embodiment 1, and the difference is that: the upper plate 12 is distributed with a circle of solder holes 121 on the edge corresponding to the position of the welding surface, and the solder holes 121 are used for injecting solder.

[0047] There are usually a large number of tiny cavities or cracks distributed on the welding surface (that is, the welding surface is uneven). When the upper plate is pressed to cover the opening of the base, the upper plate is pressed against the welding surface, which will seriously deform, twist or even break the solder on the welding surface , resulting in uneven and discontinuous structure of the brazing seam and large void area, which will affect the vacuum degree of the heat dissipation substrate, and may even overflow into the concave cavity of the base, and through the setting of the solder hole, the solder point is in the solder hole, Only the part of the injected brazing material in contact wi...

Embodiment 3

[0050] This embodiment is a modification of Embodiments 1 and 2. The change is that this embodiment is applied to a 3D heat sink, and the heat is conducted upwards through heat pipes to accelerate heat dissipation. Several heat pipes are provided on the heat dissipation substrate. , the heat pipe is provided with a set of fins, the heat pipe is a hollow tube with an opening at one end, the upper surface of the upper plate 12 is provided with a suction pipe 122 corresponding to the heat pipe, and the suction pipe 122 It includes a pre-punched hole and a flange integrated with the pre-punched hole. The flange is protruding relative to the upper surface of the upper plate. body through, and the outer wall surface of the opening end is connected to the inner wall surface of the flange in a planar manner. Changing the usual "line-surface" contact to "surface-surface" contact makes up for the shortcomings of weak welding between the heat pipe and the upper plate, and easy cracks aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com